To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

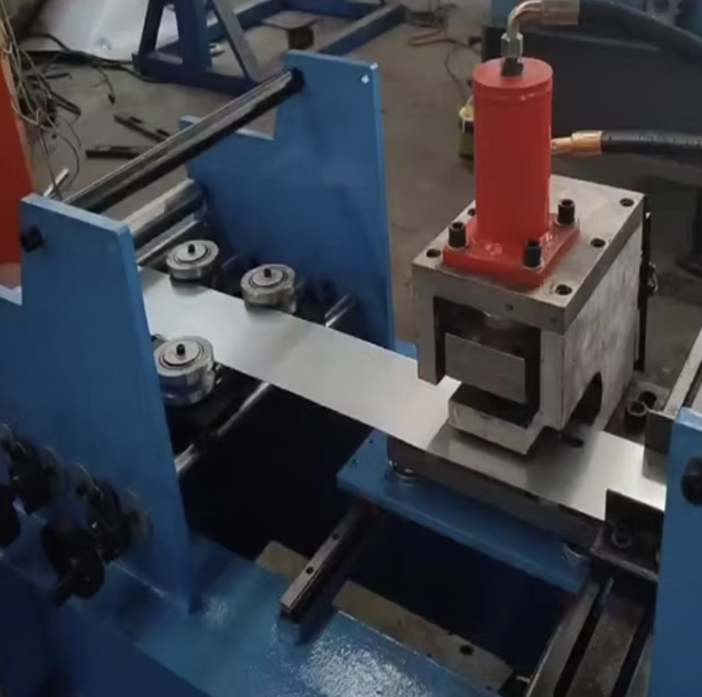

Ceiling bar roll forming machines are specialized industrial equipment designed for the efficient production of ceiling bar profiles used in suspended ceilings and lightweight construction systems. These machines offer precision, consistency, and high-speed production, making them ideal for meeting the demands of the construction and interior design industries in the USA.

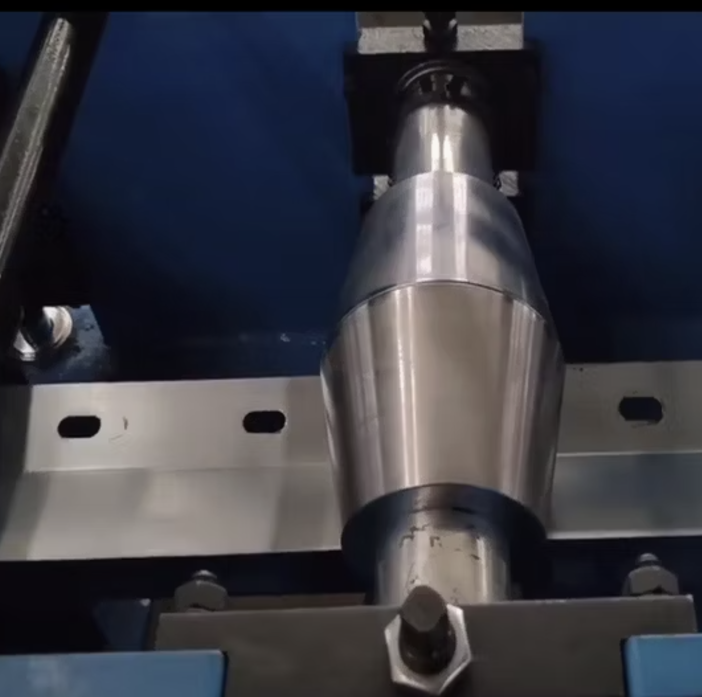

The ceiling bar roll forming machine is engineered to produce ceiling T-bars, L-bars, and other ceiling profile components. This machine uses advanced roll forming technology to shape galvanized steel, aluminum, or other lightweight metals into precise profiles.

Key features of the machine include:

Below are the typical specifications of a ceiling bar roll forming machine:

| Specification | Details |

|---|---|

| Material | Galvanized steel, aluminum |

| Material Thickness | 0.3mm – 1.0mm |

| Profile Types | T-bar, L-bar, cross-T, main T-bar |

| Roller Material | GCr15 steel with heat treatment |

| Roll Forming Stations | 12-20 stations (varies by profile type) |

| Forming Speed | 25-50 m/min |

| Main Motor Power | 5.5 kW – 7.5 kW |

| Hydraulic Cutting System | 4 kW |

| Control System | PLC system with touchscreen interface |

| Punching Mechanism | Hydraulic or servo-driven punching system |

| Voltage Requirements | 380V, 50/60Hz, 3-phase (customizable) |

| Machine Dimensions | Approx. 8m x 1.5m x 1.2m |

| Weight | 5-8 tons |

A1: The machine is designed to process galvanized steel, aluminum, and similar lightweight metals with a thickness range of 0.3mm to 1.0mm.

A2: Yes, it can manufacture various ceiling bar profiles, including T-bars, L-bars, main T-bars, and cross-T profiles, with quick die changes and adjustments.

A3: The machine operates at speeds ranging from 25 to 50 meters per minute, depending on the profile type and material used.

A4: Absolutely. The machine can be customized to meet USA voltage and power supply standards (typically 380V, 50/60Hz, 3-phase).

A5: Routine maintenance includes lubrication of moving parts, inspection of rollers and punches, and checking the hydraulic system for leaks. Detailed maintenance schedules are provided with the machine manual.

A6: Yes, it can be integrated with uncoilers, recoilers, and stacking systems for a seamless production workflow.

A7: The machine is shipped in secure packaging with installation and commissioning support available. Onsite training can also be provided.

A8: The typical lead time ranges from 6 to 10 weeks, depending on the machine's customization requirements.

Copyright 2026 © Machine Matcher.