To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

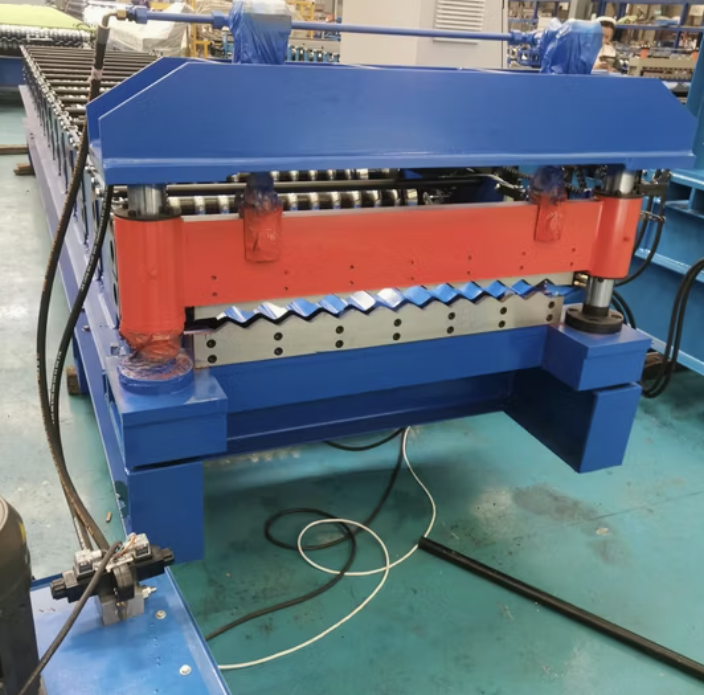

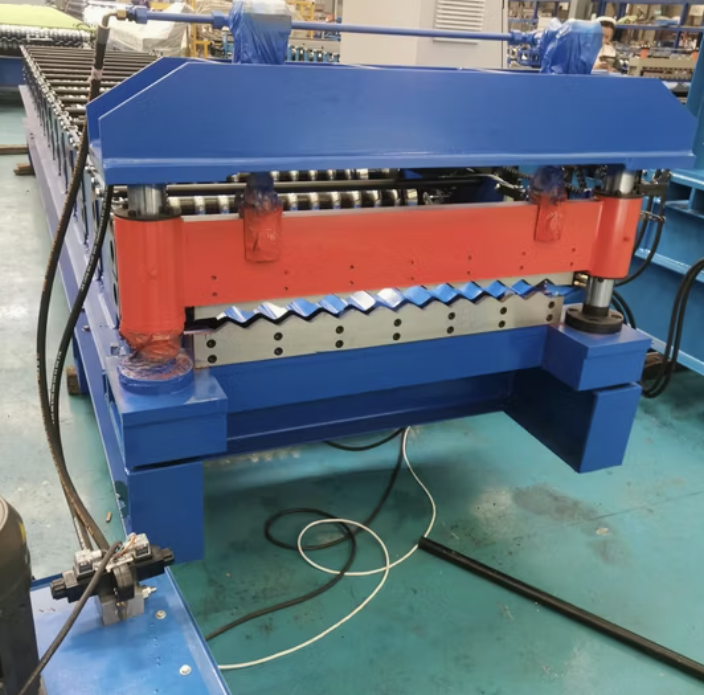

A cladding roll forming machine is a specialized piece of equipment designed to produce high-quality cladding panels used in construction for walls, roofs, and facades. These machines are engineered to handle various material types like steel, aluminum, and galvanized sheets, forming them into durable and aesthetically pleasing cladding profiles. Cladding roll forming machines are popular for their precision, efficiency, and ability to produce consistent profiles, making them ideal for construction and architectural applications in the USA.

Q1: What is the typical production capacity of a cladding roll forming machine?

A1: The production capacity depends on the material thickness and machine configuration. Typically, it ranges from 10–40 meters per minute.

Q2: Can this machine produce multiple cladding profiles?

A2: Yes, many machines come with modular tooling or adjustable rollers, allowing for multiple profile productions.

Q3: Is it possible to use recycled materials with this machine?

A3: Yes, provided the recycled material meets the necessary strength and thickness requirements.

Q4: How long does it take to set up the machine for a new profile?

A4: Profile changes typically take 1–3 hours, depending on the complexity of the design and operator experience.

Q5: What are the main applications for cladding panels produced with this machine?

A5: Cladding panels are commonly used in industrial buildings, commercial complexes, residential constructions, and agricultural structures.

Q6: What is the warranty period for cladding roll forming machines in the USA?

A6: Most manufacturers offer a warranty of 12–24 months, covering parts and labor.

Q7: Can the machine be integrated with other automation systems?

A7: Yes, modern cladding roll forming machines often come with integration capabilities for stackers, conveyors, and automated packaging systems.

Q8: What is the expected lifespan of the machine?

A8: With proper maintenance, a cladding roll forming machine can last 10–15 years or more.

Q9: Are there financing options available for buyers in the USA?

A9: Many manufacturers and distributors offer financing or lease-to-own programs to make the investment more manageable.

Q10: How can I ensure compliance with USA safety standards?

A10: Ensure the machine includes safety features such as emergency stops, enclosed guards, and OSHA-compliant designs. Regularly train operators on safety protocols.

This detailed guide will help buyers and users in the USA understand everything about cladding roll forming machines, including specifications, installation, maintenance, and usage.

Copyright 2026 © Machine Matcher.