To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

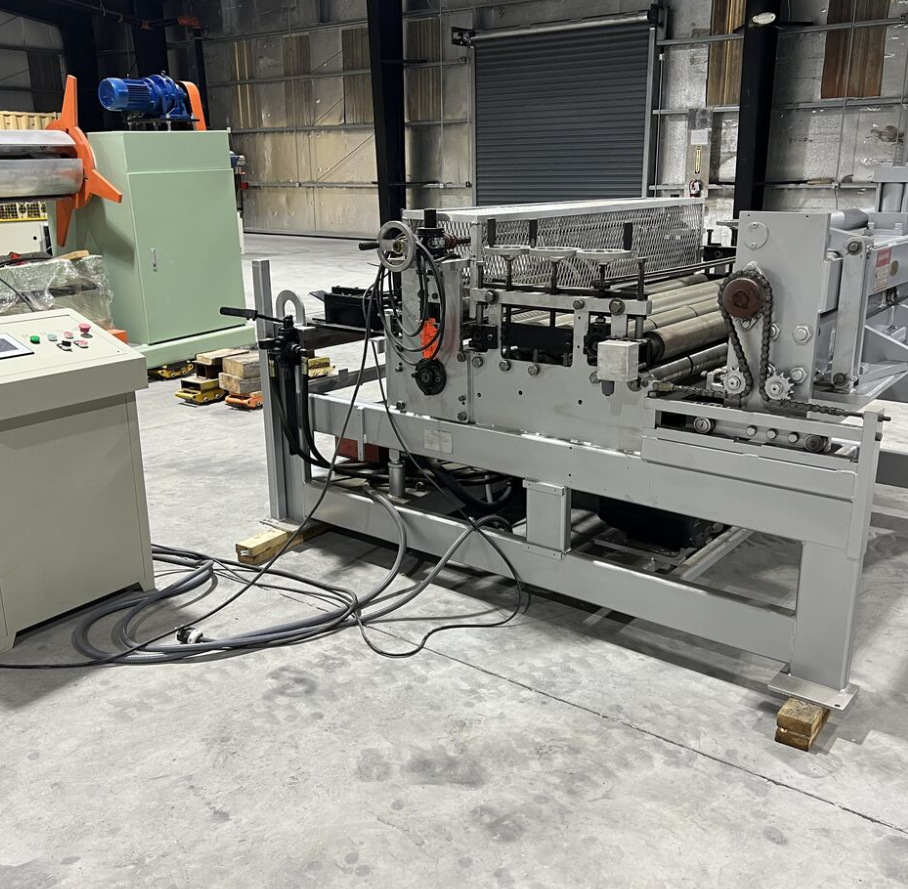

A coil slitter line machine is designed to slit large metal coils into narrower strips that can be further processed for industrial applications. This machine is essential in industries like construction, automotive, packaging, and appliance manufacturing. It efficiently cuts coils of various materials, such as steel, aluminum, copper, and stainless steel, into specific widths to meet precise manufacturing requirements.

The coil slitter line machine typically consists of components like an uncoiler, slitter head, tensioner, recoiler, and auxiliary support systems. In Florida, with its robust industrial landscape, these machines are critical for metal processing and manufacturing facilities. The state’s thriving industries rely on the precision and productivity of coil slitter lines to ensure high-quality outputs.

Q1: What industries in Florida commonly use coil slitter line machines?

A1: Industries such as construction (metal roofing and siding), automotive manufacturing, HVAC systems, and shipbuilding in Florida rely heavily on coil slitter line machines.

Q2: Can a single machine handle multiple materials like steel and aluminum?

A2: Yes, most modern coil slitter lines are designed to process various materials, but operators must adjust settings like blade pressure and tension for each material type.

Q3: What are the power requirements for a typical coil slitter line?

A3: The power requirement depends on the machine size and capacity but generally ranges from 380V to 460V, three-phase.

Q4: How do I choose the right coil slitter line machine for my business?

A4: Consider factors like coil dimensions, material type, production speed, automation features, and your specific industry needs.

Q5: Are there specific regulations for using these machines in Florida?

A5: Florida businesses must comply with OSHA regulations for machinery safety and ensure proper operator training and maintenance protocols.

Q6: What is the average lifespan of a coil slitter line machine?

A6: With proper maintenance, these machines typically last 15–20 years or more.

Q7: Can I upgrade an existing coil slitter line with new features?

A7: Yes, many manufacturers offer upgrade options, such as advanced PLC systems or additional blade configurations.

Copyright 2026 © Machine Matcher.