To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

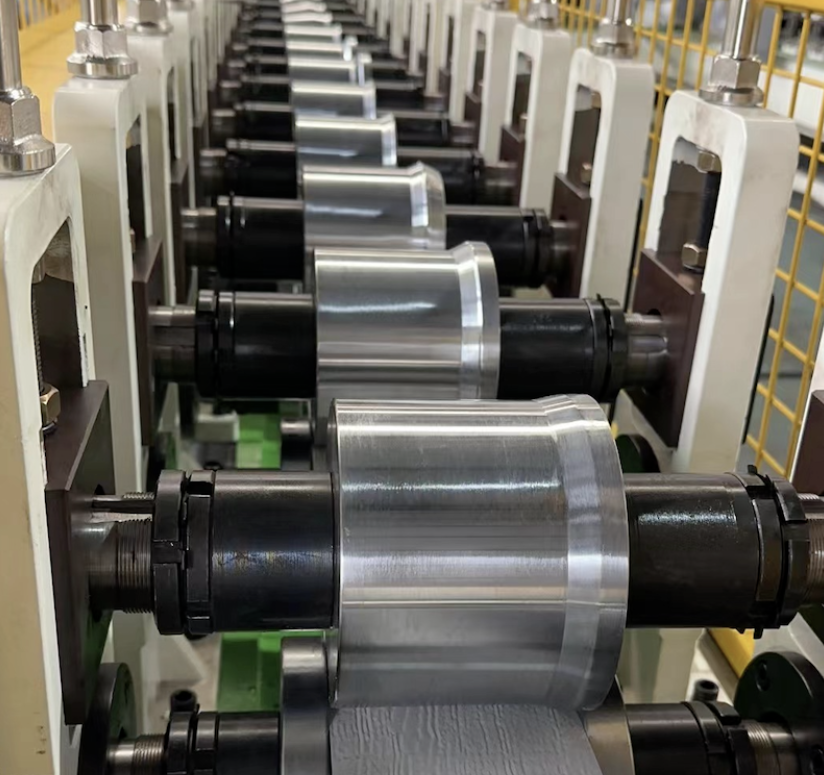

The Copper Drip Edge Roll Forming Machine is a specialized piece of equipment designed for the precise and efficient production of copper drip edges. Copper drip edges are essential components used in roofing systems to ensure proper water runoff and protection against moisture penetration. This machine is tailored to meet the specific requirements of the roofing and construction industries in the USA, where copper drip edges are highly sought after for their durability and aesthetic appeal.

The Copper Drip Edge Roll Forming Machine is engineered to produce drip edge profiles from copper sheets with exceptional precision and consistency. It is equipped with advanced features to handle the unique properties of copper, ensuring smooth operations and high-quality outputs. The machine is versatile, capable of producing various drip edge designs, and is suitable for both large-scale industrial use and smaller-scale manufacturing setups.

A copper drip edge is a metal flashing installed along the edges of roofs to direct water away from the fascia and underlying roof structures. It is crucial for protecting roofs from water damage and enhancing the roof's lifespan. Copper drip edges are particularly popular due to their corrosion resistance and elegant appearance.

Yes, the machine can also process materials like aluminum and galvanized steel, provided the thickness and properties fall within the specified range.

The production capacity depends on the profile design and material thickness. On average, it can produce 300-500 linear meters of drip edges per day under standard conditions.

Yes, training can be arranged as part of the installation package. Operators will be guided on programming, maintenance, and troubleshooting.

Installation typically takes 5-7 days, including testing and operator training.

The machine comes with a 1-year warranty covering parts and service. Extended warranties can be purchased separately.

Regular maintenance involves cleaning the rollers, inspecting the hydraulic system, and ensuring the PLC system is updated. Detailed maintenance instructions are provided in the user manual.

Yes, the machine can be customized to produce specific drip edge profiles based on the customer’s requirements.

The lead time ranges from 4-6 weeks, depending on customization and production schedules.

Yes, financing options are available through partnered financial institutions for customers in the USA.

The Copper Drip Edge Roll Forming Machine is a cutting-edge solution for manufacturers looking to produce high-quality copper drip edges efficiently. Its robust design, advanced automation, and versatility make it an indispensable tool in the roofing industry. Whether you are a large-scale producer or a small manufacturer, this machine can be tailored to meet your specific needs, ensuring superior outputs and long-term reliability.

Copyright 2026 © Machine Matcher.