To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

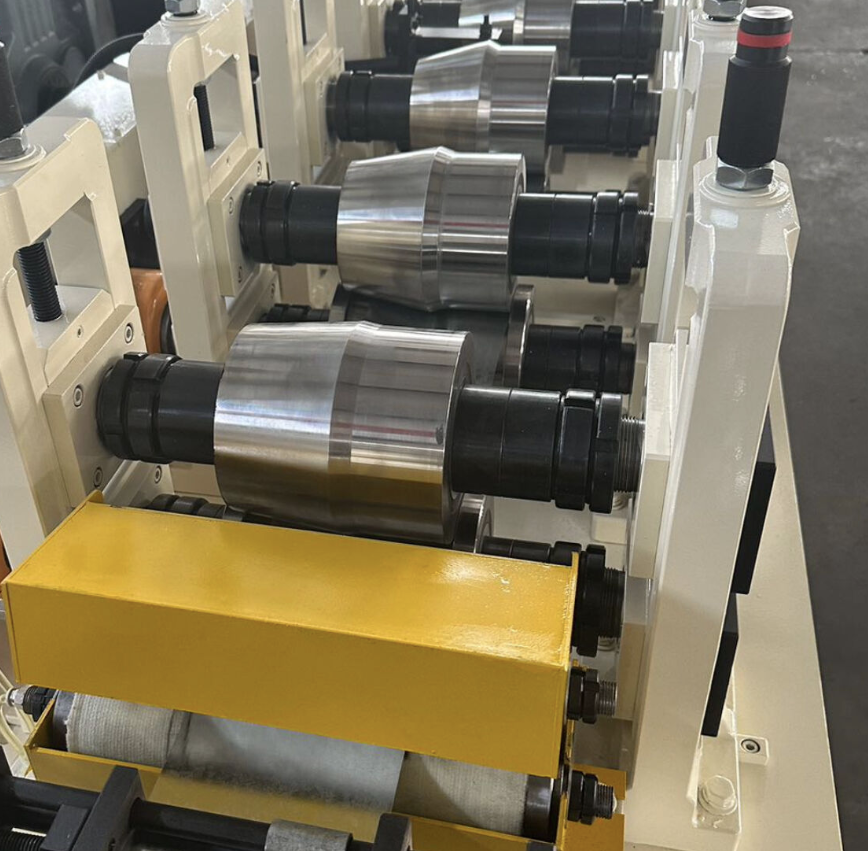

Corrugated Drip Edge Roll Forming Machine - California, USA

The Corrugated Drip Edge Roll Forming Machine is a high-speed, precision-engineered machine designed to manufacture a variety of drip edge profiles for residential and commercial roofing applications. This machine is built with durability and efficiency in mind, ensuring high-quality production at an impressive speed of 80 feet per minute. It is ideal for fabricators, contractors, and roofing manufacturers in California, USA, looking for reliable and customizable roll-forming solutions.

Industry Applications: This machine is primarily used in the roofing and construction industry, specifically for manufacturing drip edges used in residential, commercial, and industrial buildings. Drip edges are essential for directing water away from fascia boards and protecting roofs from water damage, thereby enhancing the longevity of roofing systems.

The machine can produce various drip edge profiles, including but not limited to:

Standard Drip Edge Sizes:

Common Widths (Horizontal Overhang):

Material Thickness (Gauge):

Common Materials:

All machines are new and custom-built to meet the customer’s specific profile and production requirements. Upon ordering, the machine will be shipped directly to the customer’s location from our manufacturing partner. Additional customization options, such as profile-specific rollers, enhanced control systems, and automatic stackers, are available to suit individual needs.

Machine Matcher supplies customers worldwide with high-quality roll forming machines for various applications, including:

We also provide machine sales, maintenance, repair, setup, and adjustment services for businesses in the roll-forming industry.

Pricing is determined based on optional extras and customization requirements. For a tailored quote, customers can send their profile drawings and specifications to: 📧 [email protected]

1. What power supply does the machine require? The Corrugated Drip Edge Roll Forming Machine operates on 240V three-phase power at 60 Hz, making it compatible with standard industrial power supplies in the USA.

2. How fast does the machine produce drip edges? The machine runs at a speed of 80 feet per minute, allowing for high-volume production.

3. What types of materials can the machine process? This machine is designed to handle aluminum, galvanized steel, and copper in various gauges (0.019”, 0.024”, and 0.032”).

4. Are custom profiles available? Yes, we can manufacture machines with custom roller dies to create specific drip edge profiles upon request.

5. How is the machine shipped to California? Once the order is confirmed, the machine is custom-built and then shipped directly from our manufacturing partner to your location in California.

6. What warranty comes with the machine? All machines include a one-year warranty from dispatch, covering manufacturing defects and major component failures.

7. Can you provide installation and training? Yes! Machine Matcher offers installation guidance and training to help customers set up and operate the machine efficiently.

For additional questions or inquiries, feel free to contact us at [email protected].

Copyright 2026 © Machine Matcher.