To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

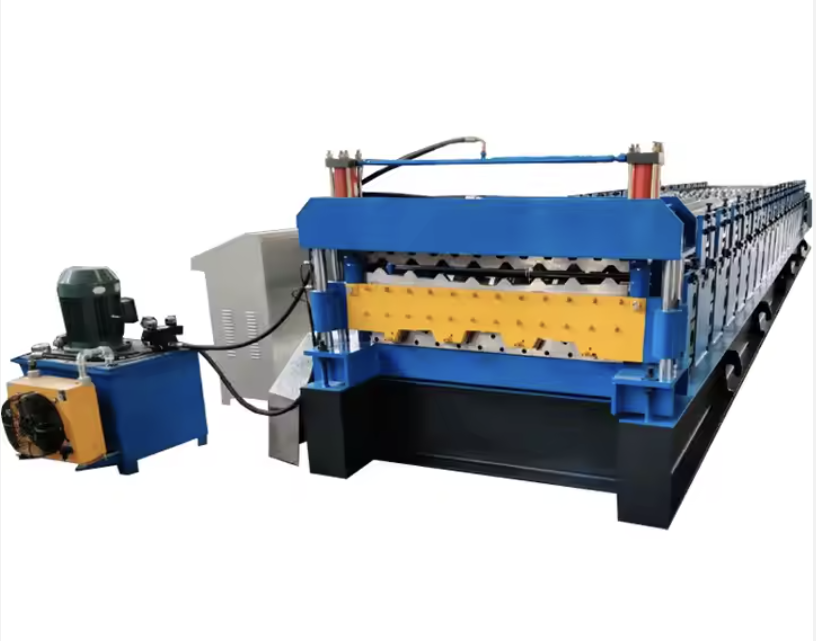

Corrugated Metal Decking Roll Forming Machine – UAE Edition

High-Speed Production with Custom Profile Capability for the UAE Construction and Steel Fabrication Industries

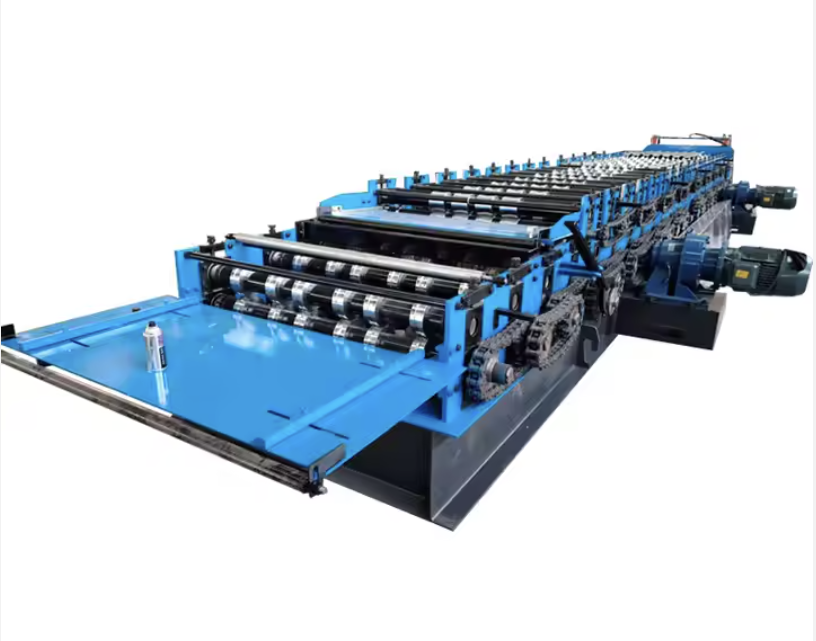

The Corrugated Metal Decking Roll Forming Machine is engineered for high-precision, continuous production of structural metal decking panels, widely used in commercial, industrial, and high-rise building construction across the United Arab Emirates. Built to handle the demanding standards of the UAE's booming infrastructure and real estate development sectors, this machine delivers exceptional speed, durability, and profile consistency.

Whether you're manufacturing floor decking for skyscrapers in Dubai, steel decking for commercial complexes in Abu Dhabi, or roofing sheets in Sharjah, this machine offers the performance and customization to meet every project’s need.

All machines are newly built and tailored to your specific profile and production requirements, and delivery is available across the UAE—from Dubai, Abu Dhabi, Sharjah, Ajman, Fujairah, Ras Al Khaimah to Umm Al Quwain.

Commercial & Industrial Construction

Infrastructure & Public Works

Prefabricated Building Manufacturers

Steel Fabrication Workshops

Real Estate Development Firms

Oil & Gas and Utility Infrastructure Projects

Corrugated decking provides excellent load-bearing support, acoustic insulation, and formwork for concrete slabs—making this machine a staple in the UAE’s rapidly growing construction industry.

| Feature | Specification |

|---|---|

| Machine Type | Corrugated Metal Decking Roll Forming Machine |

| Production Speed | Up to 20–30 meters per minute (adjustable) |

| Material Thickness Range | 0.8mm to 1.5mm |

| Material Width Range | 1000mm to 1500mm (varies by profile) |

| Material Types | Galvanized Steel, Galvalume, Cold Rolled Steel |

| Material Yield Strength | Up to 550 MPa |

| Roller Material | High-grade GCr15 steel (quenched and polished) |

| Roller Surface Treatment | Hard chrome coating for wear resistance |

| Number of Forming Stations | 20 to 32 stations (based on profile) |

| Roller Shaft Diameter | 75mm |

| Shaft Material | Solid 45# Steel, precision-machined |

| Main Drive Type | Chain or gearbox-driven (based on client preference) |

| Power (UAE compatible) | 380V / 50Hz / 3-Phase |

| Motor Power | 22 kW |

| Cutting Method | Hydraulic post-cutting system |

| Blade Material | Cr12MoV hardened tool steel |

| Control Type | PLC control system (Siemens or Delta) with HMI touch screen |

| Operating Mode | Fully Automatic, Semi-Automatic, Manual |

| De-coiling System | Hydraulic or manual de-coiler (optional 5T to 10T capacity) |

| Punching/Notching System | Optional hydraulic punching system for joint holes |

| Machine Frame | Welded steel frame with precision machining |

| Thickness of Frame Steel | 18mm |

| Profile Shape | Trapezoidal or sinusoidal corrugated deck profile |

| Profile Width and Depth | Customizable (e.g., 688mm to 960mm width, 50mm to 75mm depth) |

| Length Tolerance | ±1.0mm |

| Safety Features | Emergency stop, interlock covers, overload protection |

| Protective Covers/Guards | Yes – for chain, rollers, and moving components |

| Emergency Stop Button | Included at multiple points along the machine |

| Overload Protection System | Built into motor control systems |

This machine is built-to-order and shipped directly from our manufacturing partner to your UAE facility. Whether you're based in Dubai, Abu Dhabi, Sharjah, or any other emirate, our team ensures end-to-end logistics, setup guidance, and on-call technical support.

All Machines Are New – Customized for your profile specs

One-Year Warranty – From dispatch date

Installation & Maintenance Support – Available through our expert team

After-Sales Service – Durable parts, upgrades, and technical help

Email your profile drawings and requirements to:

📩 [email protected]

Q1: Can I customize the profile design to match UAE market standards?

A: Yes. We build the machine according to your exact profile drawing and decking shape. You can send us your dimensions and material gauge preferences for a precise quote.

Q2: What is the lead time for delivery in the UAE?

A: Lead time generally ranges from 6–10 weeks, depending on customization, shipping logistics, and optional features requested.

Q3: Is the machine suitable for heavy-duty decking used in high-rise construction?

A: Absolutely. This machine supports material up to 1.5mm thick and 550 MPa strength, ideal for structural deck applications in high-load environments.

Q4: What maintenance is required?

A: Regular lubrication of the rollers and shaft bearings, hydraulic oil level checks, electrical inspections, and keeping the PLC control system updated.

Q5: Can Machine Matcher help with installation and training?

A: Yes. We offer remote assistance, and can coordinate onsite installation and training if required.

Q6: What options are available for the de-coiler and punching units?

A: You can choose between manual or hydraulic de-coilers (up to 10T), and add hydraulic punching for holes, notches, or slab interlocks.

Q7: What is the price of the machine?

A: Pricing is based on your required profile, speed, materials, and extra systems (e.g., stackers, de-coilers, punching). Contact us with your specs for a customized quote.

Whether you're a steel fabricator in Sharjah or a construction contractor in Dubai, we can match the best corrugated decking roll forming machine for your business. Send us your:

Profile drawing or sketch

Preferred material and gauge

Estimated production speed

Power requirements

Delivery location in the UAE

📩 Email everything to [email protected]

Our team in the UK and USA is ready to assist you globally with technical advice, inspection arrangements, and custom manufacturing solutions.

Copyright 2026 © Machine Matcher.