To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

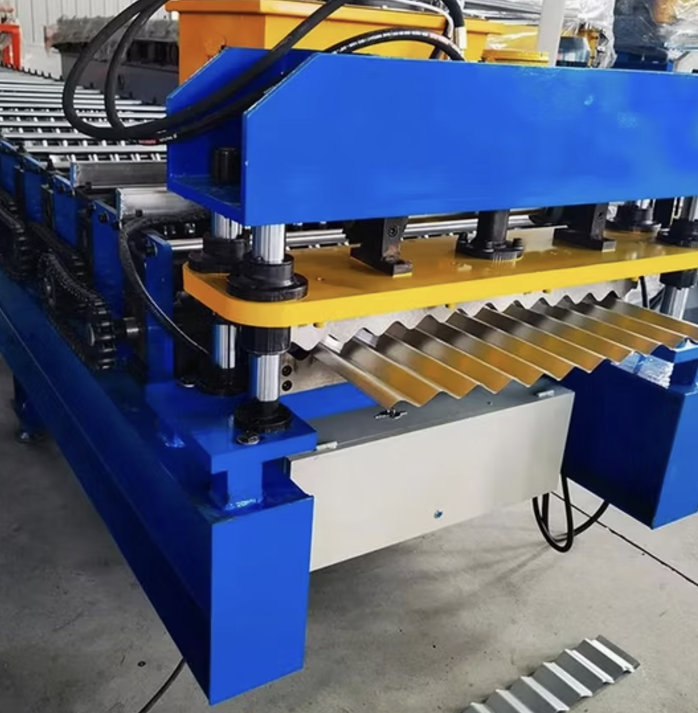

A corrugated roof panel roll forming machine is designed to produce corrugated metal panels used for roofing, cladding, and siding applications. These panels are widely recognized for their durability, aesthetic appeal, and ability to withstand harsh environmental conditions. The machine operates by feeding metal sheets into a series of rollers that shape them into the desired corrugated profile. It is an essential piece of equipment for manufacturers in the construction, agricultural, and industrial sectors.

The corrugated roof panel roll forming machine is a high-performance industrial system engineered for efficiency and precision. Equipped with advanced technology, it is capable of producing panels at high speeds while maintaining consistency in profile dimensions. The machine typically includes a decoiler, feeding mechanism, forming rollers, cutting system, and an optional stacking unit for automated operation.

Key Features:

| Feature | Details |

|---|---|

| Roller Material | High-grade steel with chrome plating for durability |

| Forming Stations | 15–20 stations (depending on the profile) |

| Material Width | 914mm–1250mm (customizable based on panel requirements) |

| Material Thickness | 0.3mm–0.8mm |

| Forming Speed | 15–25 meters per minute |

| Cutting System | Hydraulic cutting with high precision |

| Motor Power | 5.5 kW–7.5 kW (forming motor) |

| Hydraulic Station Power | 4.0 kW–5.5 kW |

| Control System | PLC with a touchscreen interface |

| Machine Dimensions | Approx. 7000mm x 1500mm x 1400mm |

| Weight | 6–8 tons |

| Optional Features | Automatic stacker, remote PLC system, and coil car |

Q1: What materials can the machine process?

A1: The machine can process galvanized steel, aluminum, pre-painted steel, and other metal sheets with a thickness range of 0.3mm–0.8mm.

Q2: Is the machine suitable for customized profiles?

A2: Yes, the machine can be customized to produce specific corrugated profiles based on customer requirements.

Q3: How easy is it to operate the machine?

A3: The machine features a user-friendly PLC control system with a touchscreen interface, making it easy to operate and adjust settings.

Q4: What maintenance is required for the machine?

A4: Regular maintenance includes cleaning and lubricating the rollers, checking the hydraulic system, and inspecting the electrical components for wear and tear.

Q5: What is the average production speed of the machine?

A5: The machine can produce corrugated panels at a speed of 15–25 meters per minute, depending on material type and thickness.

Q6: Can this machine handle large-scale production?

A6: Yes, the machine is designed for high-volume production, making it ideal for large-scale manufacturing operations.

Q7: Are there optional features for automation?

A7: Optional features include automatic stackers, remote PLC systems, and coil handling equipment for fully automated production lines.

Q8: How is the machine delivered and installed in the USA?

A8: The machine is shipped in parts and includes a detailed installation guide. Manufacturers may offer on-site installation and training services in the USA.

Copyright 2026 © Machine Matcher.