To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

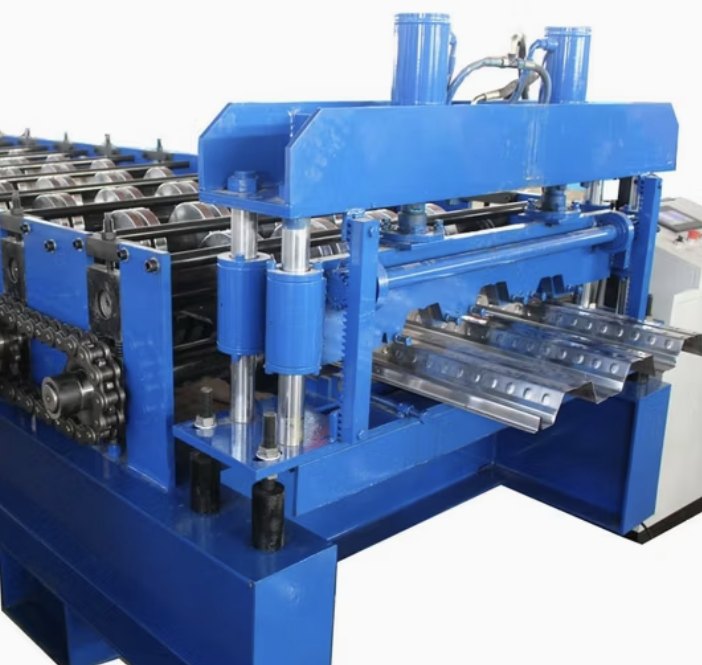

Deck roll forming machines are specialized equipment designed to produce high-quality metal decking profiles used in construction projects, such as flooring and roofing. These machines are integral in manufacturing structural steel decking panels that offer excellent strength, durability, and load-carrying capabilities. Below, we provide a full description, specifications, and a detailed question-and-answer section tailored for the U.S. market.

A deck roll forming machine is engineered to produce various types of deck profiles, such as floor decking and roof decking, widely used in commercial and industrial construction. These profiles typically serve as a base for concrete or as a roof structure for insulation and waterproofing systems.

The machine is designed for high-speed production, precise cutting, and seamless automation, making it suitable for large-scale manufacturing. It can process galvanized steel or aluminum coils to create durable and lightweight deck panels.

Deck roll forming machines cater to a wide range of U.S. industries, including:

The price can range from $50,000 to $350,000 depending on the features, speed, and level of customization required.

Typical lead time is 8 to 12 weeks, including production, quality testing, and shipping.

Yes, most manufacturers offer customization options for roller designs, punching patterns, and cutting dimensions.

The machine can be configured for either 220V/60Hz or 380V/50Hz, common in the U.S. industrial power grid.

Yes, reputable manufacturers ensure spare parts availability or offer fast shipping from their warehouses.

Many suppliers include operator training and installation support in their package.

Standard warranty periods range from 12 to 18 months, covering major components like the rollers, motors, and control system.

Yes, it is designed to handle a range of gauges from 0.7mm to 1.5mm, but consult with the manufacturer for specific configurations.

Machines should comply with UL, ANSI, and OSHA standards for safety and performance.

Most machines include a scrap management system or optional stackers to manage waste efficiently.

For businesses in the U.S., a deck roll forming machine is a vital investment that delivers efficiency, versatility, and long-term value for construction projects. Make sure to evaluate your specific requirements and consult with manufacturers to ensure the machine meets your needs

Copyright 2026 © Machine Matcher.