To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

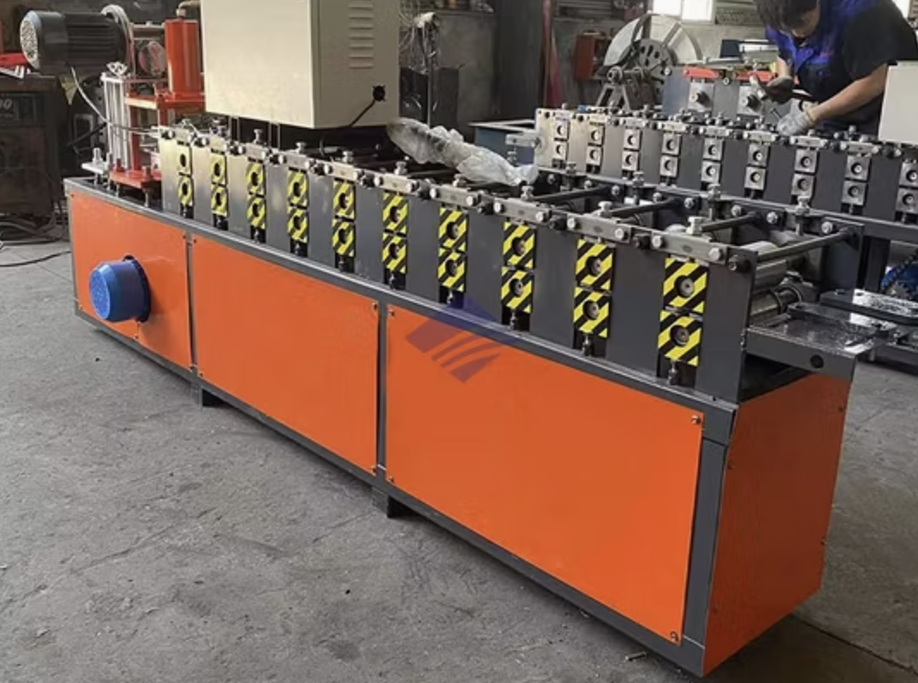

Door roll forming machines are critical in the manufacturing of high-quality door profiles for residential, commercial, and industrial use. These machines are engineered to produce consistent, precise, and durable profiles, ensuring efficiency and cost-effectiveness for manufacturers. This guide will provide a detailed overview of door roll forming machines, including their specifications, description, and a dedicated Q&A section focusing on the Brazilian market.

A door roll forming machine is designed to fabricate metal door profiles from steel, aluminum, or other metals. It is equipped with a series of rollers that progressively shape the metal strip into the desired profile. These machines are ideal for producing a variety of door components, including frames, jambs, and decorative trims.

Key features include:

1. What materials can be used with a door roll forming machine?

These machines are compatible with galvanized steel, stainless steel, and aluminum, with thicknesses ranging from 0.8mm to 2.0mm.

2. How does the machine handle customization?

Most door roll forming machines include adjustable rollers and PLC systems that allow for easy customization of profiles to suit specific requirements.

3. What power supply is needed in Brazil?

Typically, these machines operate on a 380V, 50Hz three-phase power supply, which aligns with Brazil's industrial electrical standards.

4. Are there maintenance requirements?

Yes, regular lubrication of rollers and checking of hydraulic and electrical systems are essential for optimal performance and longevity.

5. Can the machine handle high-volume production?

Absolutely, with speeds up to 25m/min, these machines are ideal for mass production.

6. Are technical support and training available?

Most manufacturers provide installation, training, and technical support, ensuring smooth operation for Brazilian users.

7. Is it possible to import these machines into Brazil?

Yes, machines can be imported. Ensure compliance with Brazilian import regulations and tariffs for industrial equipment.

Copyright 2026 © Machine Matcher.