To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

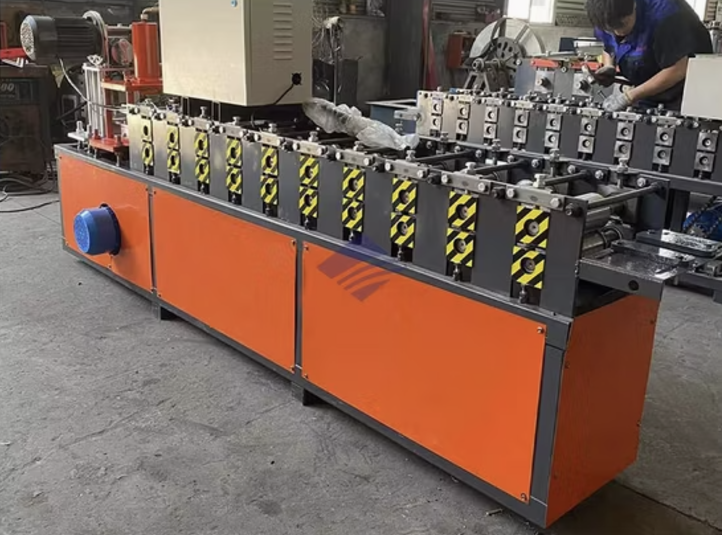

Door roll forming machines are specialized equipment designed to fabricate metal door profiles efficiently and accurately. These machines cater to industries such as residential construction, commercial establishments, and industrial facilities. Their precision and automation make them ideal for producing a variety of door profiles, including steel doors, garage doors, and industrial-grade doors.

A door roll forming machine transforms metal coils into door profiles by feeding the material through a series of rollers. Each roller station incrementally shapes the metal, ensuring high precision and uniformity. The machine can handle various materials, including galvanized steel, aluminum, and stainless steel, and is equipped with advanced features for customization and ease of operation.

This machine can manufacture a variety of door profiles, including:

Yes, the machine is versatile and can process galvanized steel, stainless steel, and aluminum with thicknesses ranging from 0.8 mm to 3.0 mm.

The machine operates at a speed of 10–20 meters per minute, depending on the complexity of the profile.

Yes, the machine can be customized to produce unique profiles. You can provide the profile drawing or sample for precise machine design.

For operations in the USA, the machine is compatible with a 220V or 440V power supply.

Optional features include punching and embossing units, automatic stackers, and remote PLC access for monitoring and control.

Depending on customization, the lead time for manufacturing and delivery ranges from 60 to 90 days.

The machine requires minimal maintenance. Regular lubrication, inspection of rollers, and periodic cleaning of the PLC system are sufficient.

Copyright 2026 © Machine Matcher.