To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

A double-layer roll forming machine is a highly efficient and versatile solution for manufacturing two different types of profiles within a single machine. This equipment is ideal for industries requiring multiple roof or wall panel designs but with limited factory space or budget constraints. The machine is commonly used for producing roofing sheets, wall panels, and other metal construction products in a variety of profiles, such as corrugated, trapezoidal, and standing seam.

The machine features two layers of roll forming stations, enabling it to produce two different profiles without the need for additional equipment or extensive changeover time. Double-layer roll forming machines are widely used in the construction, industrial, and commercial sectors in the USA.

The double-layer roll forming machine allows seamless production of two distinct profiles, such as trapezoidal roofing sheets and corrugated panels. The switching between layers is controlled through the PLC system, ensuring quick and efficient transitions.

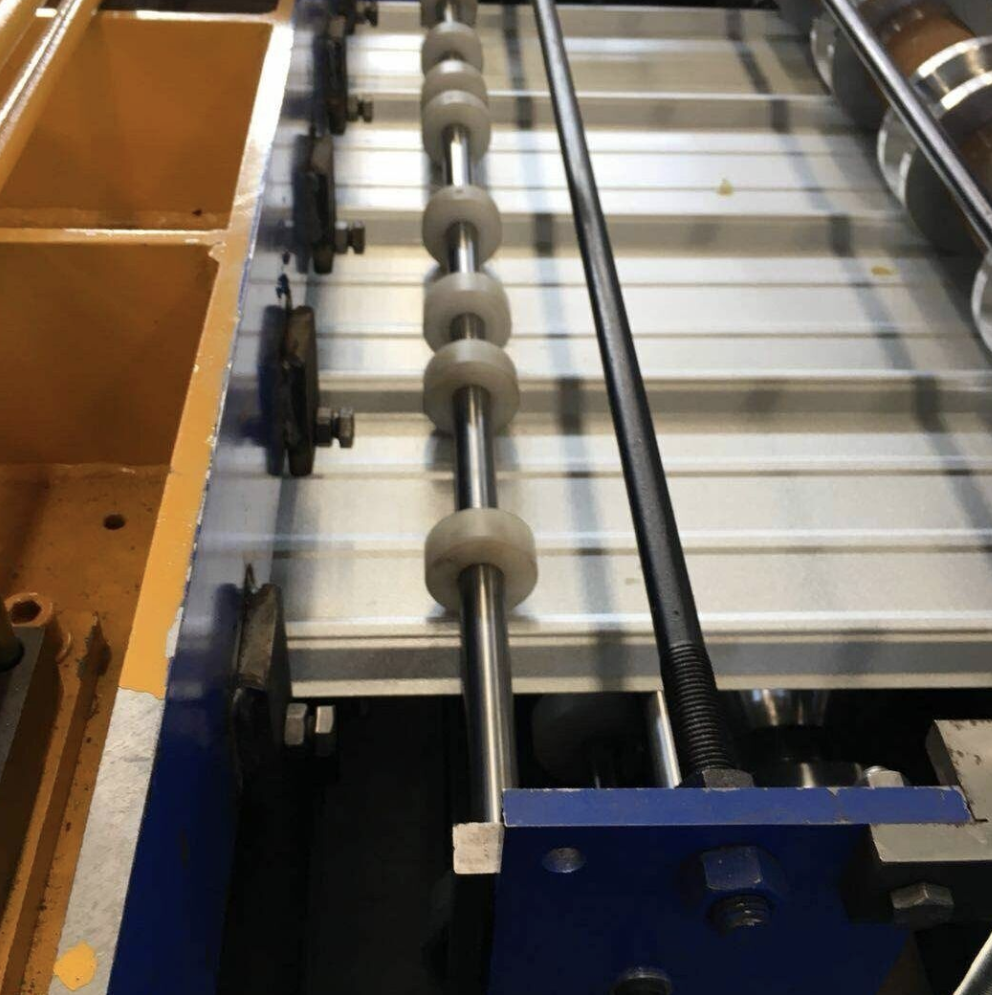

The machine is equipped with precision-ground rollers, a robust hydraulic cutting system, and an ergonomic design for operator convenience. The compact footprint makes it suitable for manufacturers with limited factory space. Its ability to produce diverse profiles without needing two separate machines offers significant cost savings for businesses.

The double-layer design also minimizes downtime by eliminating the need to change rollers frequently, making it an ideal solution for high-volume production in the competitive US market.

Yes, the machine can be customized to produce profiles that comply with ASTM standards and local building codes in the USA.

The machine is compatible with galvanized steel, aluminum, pre-painted steel, and zinc-coated sheets commonly used in the USA.

The PLC control system ensures precise roll forming operations and accurate cuts with an error margin of ±1mm. The rollers are CNC-machined for consistency.

Yes, optional add-ons such as embossing rollers, hydraulic pre-cutting, and automatic stackers can be included based on customer needs.

The delivery time ranges from 30 to 60 days, depending on the level of customization required.

Pricing typically ranges between $30,000 and $60,000, depending on the features, customization, and manufacturer.

Yes, the machine can be shipped to any US location. Installation and training are usually provided by the manufacturer or local distributors.

Most machines come with a warranty of 12–18 months for critical components, including the motor, rollers, and PLC system.

A double-layer roll forming machine is an investment that boosts productivity and flexibility while maintaining the quality demanded by the US market.

Copyright 2026 © Machine Matcher.