To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

Dovetail Deck Roll Forming Machine – UAE Market

The Dovetail Deck Roll Forming Machine is a high-performance industrial solution engineered to manufacture precision dovetail steel deck profiles used in composite slab systems for multi-story commercial buildings, infrastructure, and industrial construction. Known for its excellent strength-to-weight ratio, dovetail decking ensures reliable structural performance, improved load distribution, and compatibility with mechanical fastening systems, making it a preferred choice for engineers and developers in the UAE’s booming construction sector.

Machine Matcher proudly supplies new, custom-built dovetail deck roll forming machines across the United Arab Emirates, including Abu Dhabi, Dubai, Sharjah, and beyond. Every unit is built to match customer-specific profile designs, material gauges, and performance requirements, with direct delivery from trusted global manufacturing partners.

The Dovetail Deck Roll Forming Machine is designed for continuous high-speed production of dovetail profiles with uniform accuracy and long-term durability. With a robust frame, precisely machined rollers, and a reliable hydraulic cutting system, this machine operates efficiently under UAE conditions and power standards, supporting high-output commercial steel deck manufacturing.

Ideal for:

Composite floor slab production

High-rise building construction

Parking garages

Warehouses and industrial structures

Steel frame buildings in seismic zones

Machine Type: Automatic Dovetail Deck Roll Forming Machine

Production Speed: 15–30 meters/min (adjustable based on material and design)

Material Thickness Range: 0.8mm – 1.5mm

Material Width Range: 1000mm – 1250mm

Material Types: Galvanized steel, Galvalume, Cold-rolled steel, Aluminum (on request)

Material Yield Strength: Up to 550 MPa

Roller Material: GCr15 (high-grade alloy steel), precision-machined

Roller Surface Treatment: Hard chrome plating for anti-rust and smooth forming

Number of Forming Stations: 20–26 (depending on profile complexity)

Roller Shaft Diameter: 70mm–90mm

Shaft Material: Solid 45# steel, quenched and tempered

Main Drive Type: Gearbox or chain drive (as per customization)

Power (UAE standard): 380V, 3 Phase, 50Hz

Motor Power: 15kW–22kW depending on configuration

Cutting Method: Hydraulic post-cut system for clean and accurate cutting

Blade Material: Cr12Mov high-grade steel with heat treatment

Control Type: PLC automatic control (brands like Siemens/Mitsubishi)

Operating Mode: Touchscreen HMI + manual/auto switch

De-coiling System: 5–10 ton manual or hydraulic uncoiler (optional)

Punching/Notching System: Optional inline hydraulic system available

Machine Frame: Welded steel structure with stress relief

Thickness of Frame Steel: 18–22mm

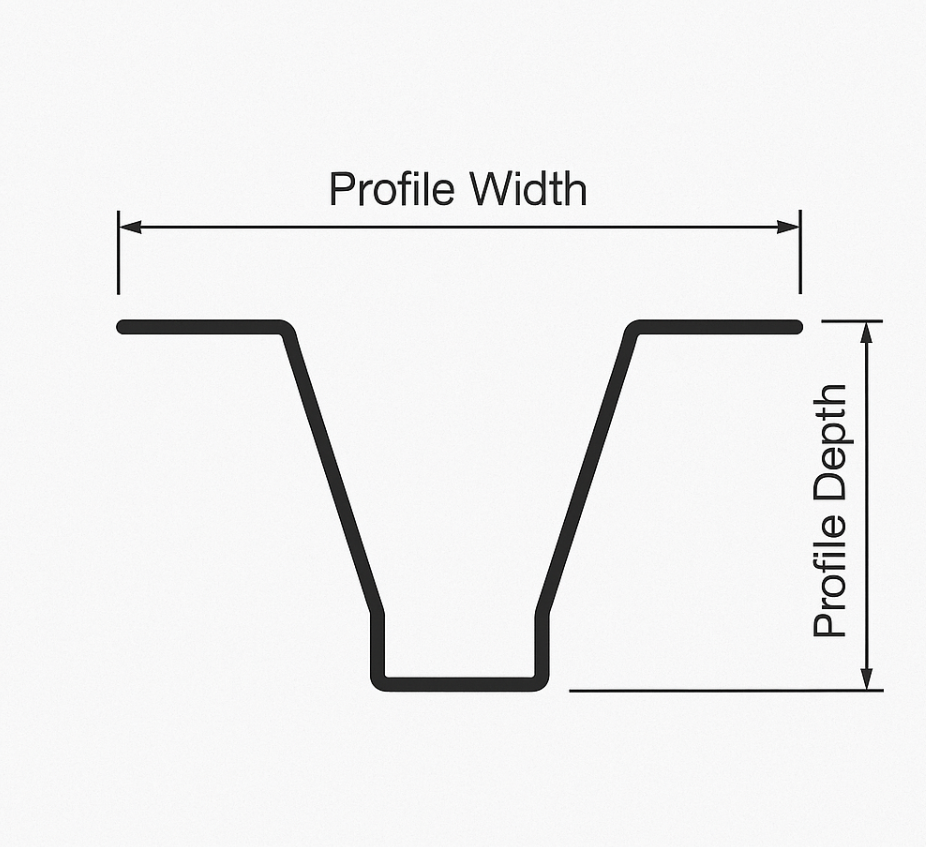

Profile Shape: Dovetail deck with interlocking side ribs and flat top

Profile Width and Depth: Approx. 600mm–750mm wide, 50–75mm deep (customizable)

Length Tolerance: ±2mm per 6m

Safety Features:

Protective Covers/Guards over moving parts

Emergency Stop Button

Overload Protection System

Fault detection alarms and sensors

Prices Start From: Approx. $65,000 USD (basic model)

What Affects Final Price:

Profile design complexity

Required thickness range

Punching or embossing features

Hydraulic vs. manual uncoiler

Control system brand (Siemens, Mitsubishi, Delta, etc.)

Speed and automation level

Installation and training services

All machines are new and custom-built. Delivery is available anywhere in the United Arab Emirates. We provide complete support from design confirmation to after-sales service.

With the UAE’s rapid expansion in real estate, infrastructure, and high-rise development, dovetail deck systems are increasingly popular in:

Multi-story commercial buildings

Industrial complexes

Metro and rail projects

Modular structures

Airports and terminals

Builders in Dubai and Abu Dhabi especially favor dovetail deck profiles for use in fire-rated floor systems and areas requiring composite action between steel and concrete.

All machines are delivered directly to your site in UAE

Covered by a 1-year warranty from date of dispatch

Lifetime technical support and durable maintenance packages available

Remote and on-site commissioning support provided as needed

To ensure the most accurate quote, customers are encouraged to send:

Profile drawing with dimensions

Preferred thickness range

Required output speed

Power supply details

Delivery location in UAE

Send all details to: [email protected]

Q1: Can I use this machine to make other profiles besides dovetail deck?

A1: This machine is optimized for dovetail deck only. However, custom multi-profile or interchangeable tooling options are available upon request.

Q2: Is installation included in the price?

A2: Installation is not included by default, but on-site or remote installation support and operator training are available as add-ons.

Q3: How long does it take to manufacture and deliver the machine to the UAE?

A3: Standard lead time is 70–90 days from order confirmation to dispatch, plus shipping time to UAE.

Q4: Can I use this machine in hot and dusty environments like construction zones in the UAE?

A4: Yes. The machine is designed with robust materials and sealed electronics to handle high temperatures and industrial conditions.

Q5: What is the required maintenance schedule?

A5: Basic maintenance includes weekly lubrication, monthly inspection of electrical components, and roller cleaning. A full preventive maintenance checklist is provided with each machine.

This machine is available for delivery across all Emirates:

Dubai, Abu Dhabi, Sharjah, Ajman, Umm Al Quwain, Ras Al Khaimah, and Fujairah.

Machine Matcher is your trusted partner in delivering custom-engineered roll forming machines to your UAE construction projects. With expert guidance, global sourcing, and localized support, we ensure you receive the right machine at the right price, fully backed by after-sales care.

Copyright 2026 © Machine Matcher.