To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

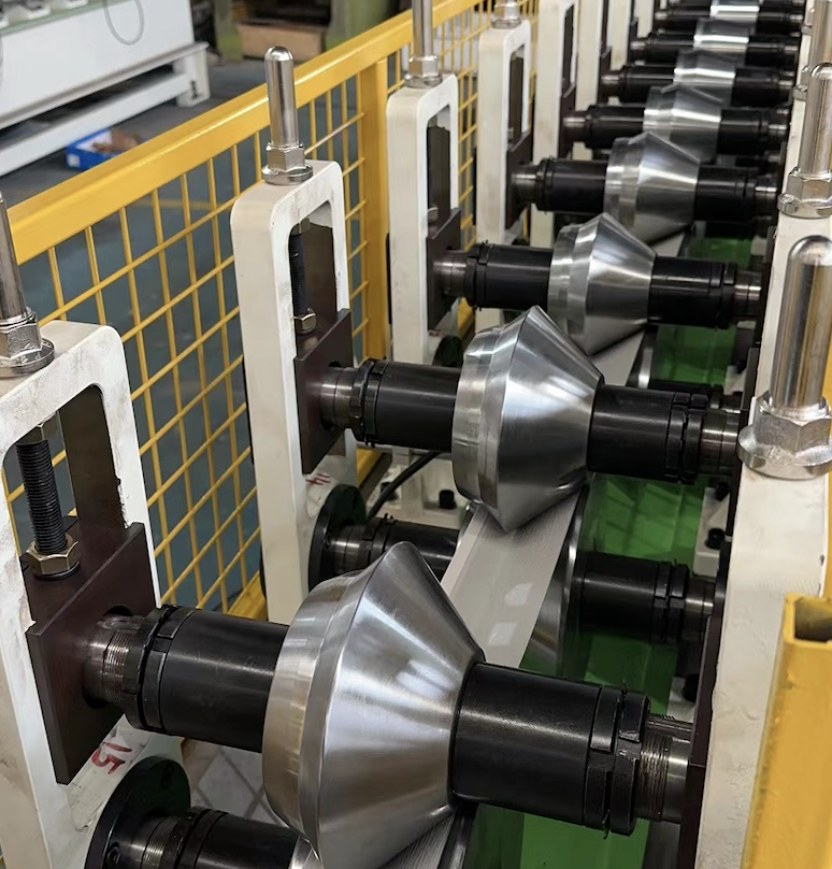

The Drip Edge 2” x 2” Roll Forming Machine is a high-performance solution designed to manufacture precise and durable drip edges for residential and commercial roofing systems. Located in Arizona, USA, this machine is custom-built to meet specific profile and operational requirements, ensuring compatibility with a wide range of materials and roofing applications.

Manufactured by our trusted partners, this machine is shipped directly to the customer’s location, providing a seamless purchase and installation experience. With a focus on quality and precision, the Drip Edge Roll Forming Machine is ideal for contractors, roofing companies, and manufacturers seeking efficiency and reliability in drip edge production.

This roll forming machine is tailored for the roofing and construction industries, where drip edges are essential for directing water away from roofs and preventing damage to underlying structures. It is suitable for producing drip edges for:

Standard Drip Edge Sizes:

Common Widths (Horizontal Overhang):

Material Thickness (Gauge):

Materials:

Available Profiles:

Pricing for the Drip Edge 2” x 2” Roll Forming Machine is determined based on optional extras and specific customization requirements. For a detailed and tailored quote, please contact us with your specifications.

Email: [email protected]

Phone: Available upon request.

1. What is the lead time for the Drip Edge 2” x 2” Roll Forming Machine?

Answer: Lead times vary based on customization and production schedules. Typically, it ranges from 6 to 8 weeks. Contact us for more accurate timelines.

2. Can this machine produce custom drip edge profiles?

Answer: Yes, we offer customization to accommodate unique profile requirements. Provide your profile drawings to [email protected] for a detailed quote.

3. What materials can this machine process?

Answer: It can process aluminum, galvanized steel, and copper in various gauges, ensuring flexibility for different roofing applications.

4. How is the machine shipped to Arizona?

Answer: The machine is shipped directly from our manufacturing partner to your location in Arizona, USA. We handle all logistics to ensure safe and timely delivery.

5. What power requirements does this machine have?

Answer: It requires a 240V three-phase 60 Hz power supply, which is standard for industrial equipment in the USA.

6. Does Machine Matcher provide installation and training?

Answer: Yes, we offer setup assistance and training to ensure efficient operation of the machine.

For more information or to get a personalized quote, contact us at [email protected].

Copyright 2026 © Machine Matcher.