To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

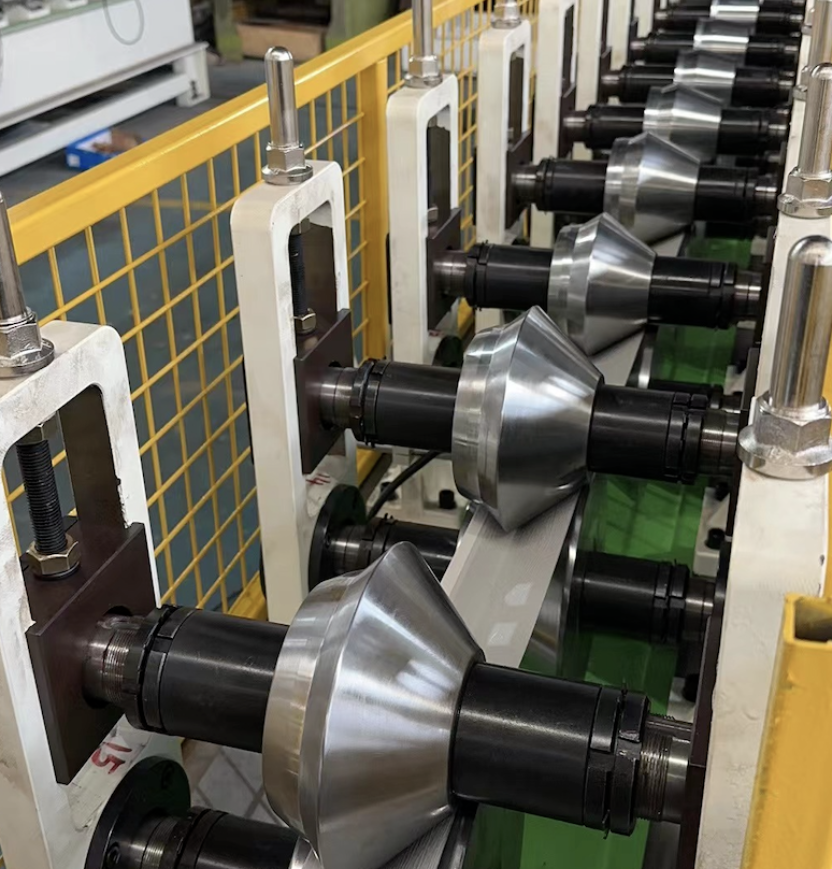

Machine Matcher is proud to present the Drip Edge Fascia Roll Forming Machine – a top-of-the-line solution for manufacturing precision drip edge profiles in Alaska, USA. Designed for the demanding conditions of the Alaskan roofing and construction industries, this machine combines robust construction, precision engineering, and customization capabilities to meet specific profile and production requirements.

The Drip Edge Fascia Roll Forming Machine is built to create a variety of drip edge profiles, ensuring superior protection against water infiltration for both residential and commercial roofing systems. With the ability to produce profiles with different face sizes and material thicknesses, this machine is an ideal choice for metal roofing contractors, building suppliers, and manufacturers specializing in roofing components in Alaska.

Manufactured with high-grade components, the machine offers durability and reliability even in the challenging weather conditions of Alaska. It comes with an electric shear for clean, accurate cuts and operates at an impressive speed of 80 feet per minute, making it perfect for high-volume production needs.

Standard Drip Edge Sizes:

Common Widths (Horizontal Overhang):

Other Profiles:

The Drip Edge Fascia Roll Forming Machine is a valuable asset for:

All machines are new and custom-built to match specific profile and machine requirements. Optional extras and customization features are available to enhance productivity and efficiency.

Pricing: Determined based on optional extras and customization requirements.

For a tailored quote, contact us directly or email your requirements, including profile drawings, to [email protected].

1. What profiles can the Drip Edge Fascia Roll Forming Machine produce?

This machine can produce a range of standard and custom profiles, including C5, C6, F4, 90 Degree, D Style, FHA, and others. Custom profiles can be designed based on your specifications.

2. What is the lead time for delivery to Alaska?

Lead times vary based on customization requirements. Typically, delivery can take between 6 to 10 weeks. Contact us for a more accurate estimate based on your order.

3. Is training included with the machine purchase?

Yes, comprehensive training on setup, operation, and maintenance is included to ensure smooth integration into your production line.

4. What is the warranty coverage for this machine?

The machine comes with a 1-year warranty covering parts and service from the date of dispatch.

5. Can this machine handle thicker materials for commercial roofing applications?

Absolutely! The machine is capable of processing materials with thicknesses of 0.019 inch, 0.024 inch, and 0.032 inch, making it suitable for both residential and commercial applications.

6. How can I get a quote?

To get a tailored quote, please send your profile drawings or any specific requirements to [email protected] or use our contact form on Machine Matcher.

7. Does Machine Matcher provide after-sales support in Alaska?

Yes, we offer full after-sales support, including maintenance, repair services, and spare parts, to ensure uninterrupted production.

Ready to Upgrade Your Production Capabilities?

Contact Machine Matcher today for a tailored quote and to learn more about how the Drip Edge Fascia Roll Forming Machine can streamline your production in Alaska.

Email: [email protected]

Website: Machine Matcher

Invest in precision and efficiency with the Drip Edge Fascia Roll Forming Machine – custom-built for the Alaskan market!

Copyright 2026 © Machine Matcher.