To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

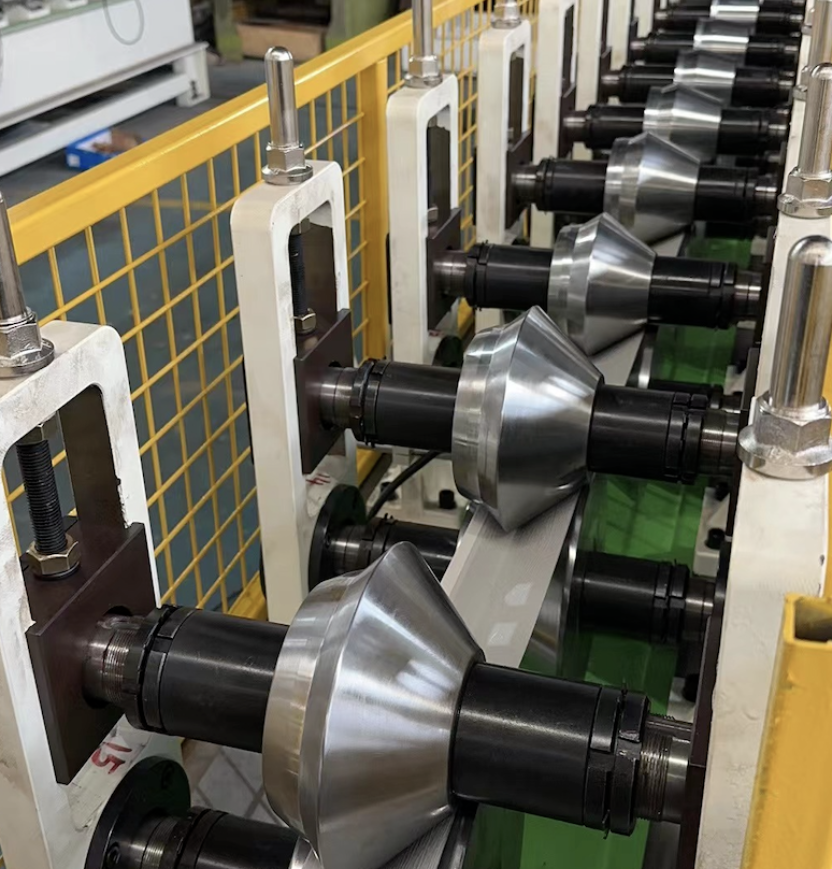

The Drip Edge Flashing Roll Forming Machine is a custom-built, high-precision solution designed for manufacturers and contractors in the roofing industry across Arkansas, USA. This machine is engineered to produce a wide range of drip edge profiles efficiently, making it ideal for both residential and commercial roofing applications. With a focus on quality and customization, each machine is built to meet specific profile and performance requirements, ensuring a seamless fit for your production needs.

Machine Matcher supplies this advanced roll forming equipment directly from our manufacturing partners, ensuring top-notch quality and timely delivery to your location. We also offer comprehensive maintenance, repair, and setup services to keep your production line running smoothly.

The machine can produce a variety of drip edge profiles to suit different roofing needs:

The Drip Edge Flashing Roll Forming Machine is widely used in the roofing industry, serving:

This machine ensures precise and efficient production of drip edges, enhancing the longevity and performance of roofing systems by directing water away from the roof and preventing damage.

These add-ons help optimize productivity and reduce manual handling, making the production process more efficient.

All machines are new and built to order, ensuring they meet your specific profile and production requirements. The machine will be shipped directly to your location in Arkansas from our manufacturing partner. Pricing is customized based on the optional extras and specific requirements. Contact us for a tailored quote.

Email your profile drawings or specifications to: [email protected] to get the best quote.

A1: This machine can process aluminum, galvanized steel, and copper in various thicknesses, including 0.019, 0.024, and 0.032 inches.

A2: Yes, it is fully customizable to produce custom profiles based on your requirements. Simply provide your profile drawings to get started.

A3: The machine operates at a maximum speed of 80 feet per minute, ensuring efficient production.

A4: Yes, we offer comprehensive support, including maintenance, repair, and adjustments. The machine also comes with a 1-year warranty.

A5: Pricing is based on your customization needs and optional extras. Contact us for a tailored quote.

A6: Yes, our team can help with setup and integration into your existing production line, ensuring seamless operation.

For more information or to request a quote, contact Machine Matcher or send an email to [email protected].

Copyright 2026 © Machine Matcher.