To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

Drip Edge Flashing Roll Forming Machine - Colorado, USA

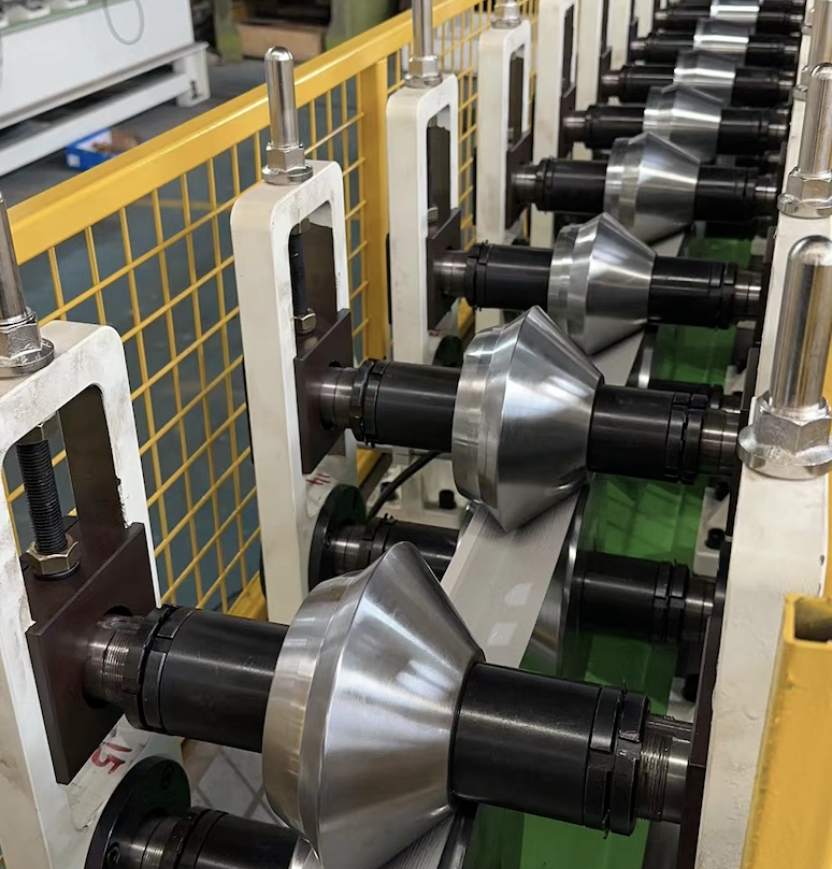

The Drip Edge Flashing Roll Forming Machine is an advanced solution for manufacturing high-quality drip edge profiles tailored for the roofing and construction industries. Designed to deliver precision, speed, and efficiency, this machine is ideal for businesses looking to streamline their metal trim production.

Manufactured to meet industry standards, this roll forming machine is equipped with 10 forming stands and an electric shear, ensuring clean and accurate cuts. With a maximum speed of 80 feet per minute, it provides high-output production without compromising on quality. The machine operates on 240V three-phase power at 60Hz, making it suitable for commercial and industrial applications across Colorado and the wider U.S. market.

The Drip Edge Flashing Roll Forming Machine is primarily used in roofing and construction industries for fabricating high-quality drip edge flashing. These components play a critical role in protecting roofs from water damage by directing runoff away from the fascia and preventing leaks. This machine is suitable for:

This machine supports multiple drip edge profiles and sizes to accommodate various project needs, including standard and custom profiles:

Each machine is new and custom-built to meet specific profile and production requirements. Once an order is confirmed, the machine is manufactured and shipped directly to the customer's location from our trusted production partner. Customization options include additional profile designs, automatic stackers, and remote PLC system integration.

Pricing is determined based on optional extras and specific customization requests. Contact Machine Matcher for a tailored quote.

Machine Matcher is a global supplier of roll forming equipment, including:

In addition to machine sales, we offer maintenance, repair, setup, and adjustment services for roll forming industries worldwide.

For quotes and inquiries, send profile drawings and specifications to [email protected].

The Drip Edge Flashing Roll Forming Machine can handle aluminum, galvanized steel, and copper. Material thicknesses range from 0.019 to 0.032 inches.

The machine operates at 80 feet per minute, allowing for high-volume production.

Yes! We offer custom profile manufacturing based on your specific requirements. Send us your profile drawings for a custom quote.

The machine runs on 240V three-phase power at 60Hz, which is standard for industrial applications in the U.S.

All machines come with a 1-year warranty from the date of dispatch. Maintenance and repair support are available.

Shipping timelines vary based on customization and order volume. Contact us for an estimated lead time.

Yes! We offer installation and setup assistance, ensuring that your machine is fully operational upon delivery.

For additional questions or a custom quote, contact us at [email protected] or visit our website.

Copyright 2026 © Machine Matcher.