To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

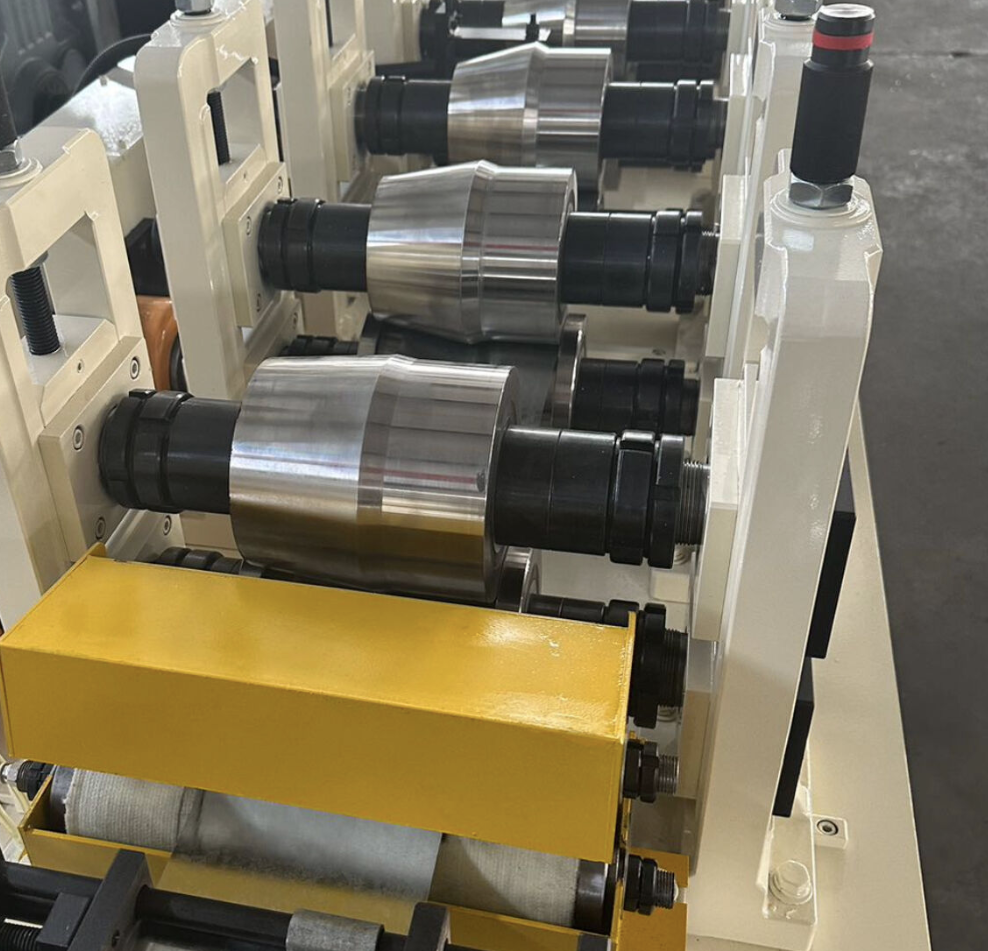

A drip edge roll forming machine is designed to produce drip edges, an essential component in roofing systems. Drip edges are metal strips installed along roof edges to direct water away from the fascia and into the gutter system, protecting roofs and underlying structures from water damage. These machines offer precision, efficiency, and customization for producing high-quality drip edges suitable for residential, commercial, and industrial roofing applications.

Arizona's unique climate, characterized by intense sun and occasional monsoonal rains, makes high-quality drip edges crucial for protecting buildings from water damage and maintaining structural integrity. The drip edge roll forming machines cater to this demand, enabling manufacturers and contractors in Arizona to meet local building codes and customer requirements effectively.

| Component | Specification |

|---|---|

| Roller Materials | High-grade chromium-plated steel for durability and corrosion resistance. |

| Frame Size | Heavy-duty welded steel frame, typically ranging from 350mm to 450mm in width. |

| Motors | Servo motor-driven rollers for precision; motor power ranges from 7.5 kW to 15 kW. |

| PLC System | Advanced PLC control for easy operation, automatic adjustment, and high efficiency. |

| Machine Speed | Up to 30m/min (adjustable depending on material type and thickness). |

| Material Thickness | 0.3mm - 0.8mm (varies by model). |

| Profile Materials | Galvanized steel, aluminum, and coated steel sheets suitable for Arizona's climate. |

| Cutting System | Hydraulic cutting system with a tolerance of ±0.5mm for precise profile lengths. |

| Safety Features | Safety guards and emergency stop buttons for operator safety. |

| Power Supply | Compatible with Arizona’s standard power supply (typically 220V/60Hz or 440V/60Hz). |

| Dimensions | Machine length ranges from 6m to 10m, with a width of 1.5m to 2m, depending on customization. |

| Weight | Approximately 5 tons, varies with machine size and configuration. |

Drip edge roll forming machines are highly relevant for Arizona’s roofing industry due to the state’s unique climate challenges. Roofing contractors, construction firms, and metal fabrication businesses in Arizona can leverage these machines to produce drip edges tailored to local requirements, ensuring compliance with state building codes and durability against extreme weather conditions.

Q1. What materials can be processed by the drip edge roll forming machine?

A1. The machine can process galvanized steel, aluminum, and coated steel sheets, which are ideal for Arizona's climatic conditions.

Q2. What is the production speed of the machine?

A2. The production speed is up to 30m/min, depending on the material thickness and profile design.

Q3. Can the machine be customized for different drip edge profiles?

A3. Yes, the machine can be customized to produce various profiles to meet specific project requirements.

Q4. What is the power requirement for the machine?

A4. The machine is compatible with 220V/60Hz or 440V/60Hz power supplies, suitable for Arizona’s industrial standards.

Q5. How long does installation and setup take?

A5. Installation and setup typically take 1-2 days, depending on the site and operator experience.

Q6. Are there any additional features to improve efficiency?

A6. Optional features like stackers, remote PLC systems, and uncoilers/recoilers can enhance production efficiency.

Copyright 2026 © Machine Matcher.