To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

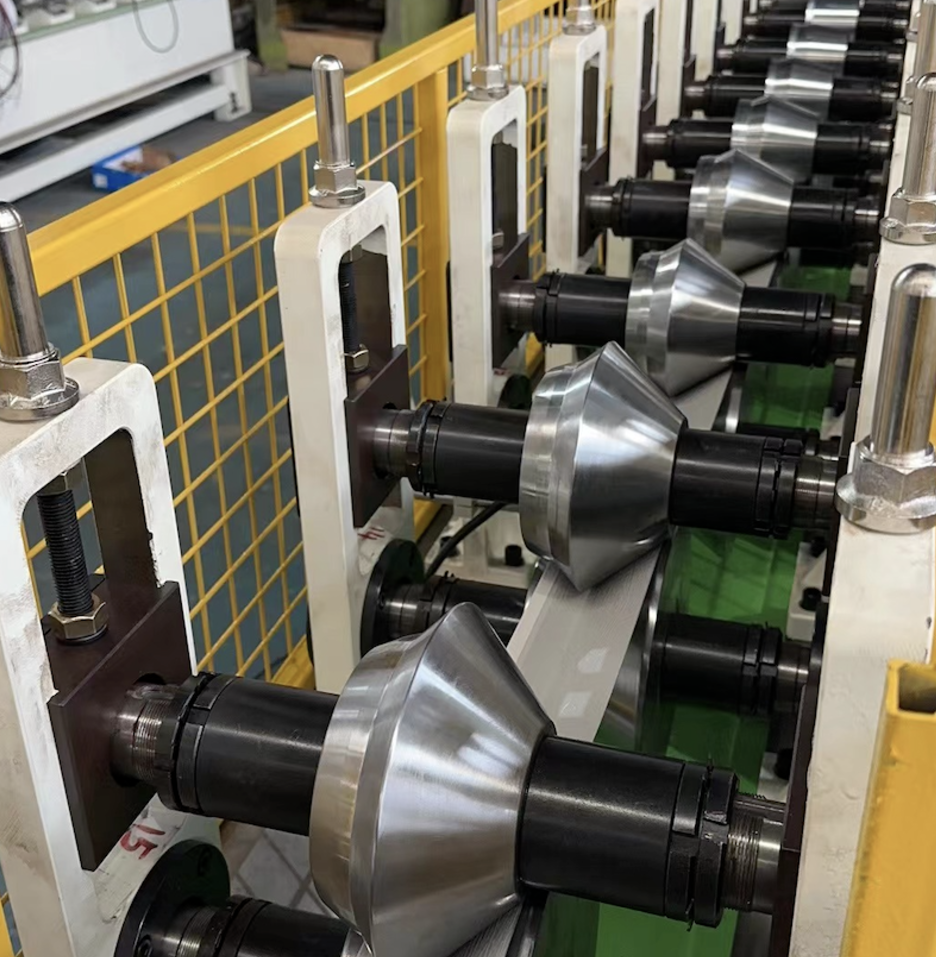

The F4 Drip Edge Cold Roll Forming Machine is a high-precision, automated system designed to produce drip edge profiles for roofing and siding applications. These profiles are widely used to protect building exteriors by directing water away from roofs and walls, enhancing durability and appearance. This machine is ideal for manufacturers looking to produce consistent, high-quality drip edge profiles with efficiency and reliability.

The F4 model offers advanced technology, including a computerized PLC system for accurate control, a durable frame for stability, and precision rollers crafted from high-grade materials to ensure consistent shaping and long-term use. The machine is equipped with an efficient hydraulic cutting system for clean and precise cuts, even on thicker gauges.

The machine is designed to produce a variety of drip edge profiles, including straight, curved, and custom shapes as per client requirements. Profile drawings are essential for custom configurations.

The machine supports galvanized steel, aluminum, and pre-painted steel with a thickness ranging from 0.3 mm to 0.8 mm. Additional materials can be tested upon request.

The machine includes an optional uncoiler for smooth material feeding. The feeding system ensures minimal wastage and precise alignment.

Yes, the machine can be equipped with a remote PLC monitoring system, allowing operators to oversee operations and troubleshoot issues from a distance.

With a forming speed of 15–30 meters per minute, production time depends on the batch size and complexity of the profile.

Absolutely! The machine can be tailored to meet specific requirements, including unique profiles, speed adjustments, and additional safety features.

The F4 model includes full safety enclosures, emergency stop buttons, and complies with international safety regulations to ensure operator safety.

The machine comes with a 12-month warranty covering parts and labor, excluding wear-and-tear components like rollers and blades.

The typical lead time is 30–60 days, depending on customization and shipping requirements.

Yes, the power supply can be customized to match the standards of your region, such as 220V/60Hz or 400V/50Hz.

Copyright 2026 © Machine Matcher.