To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

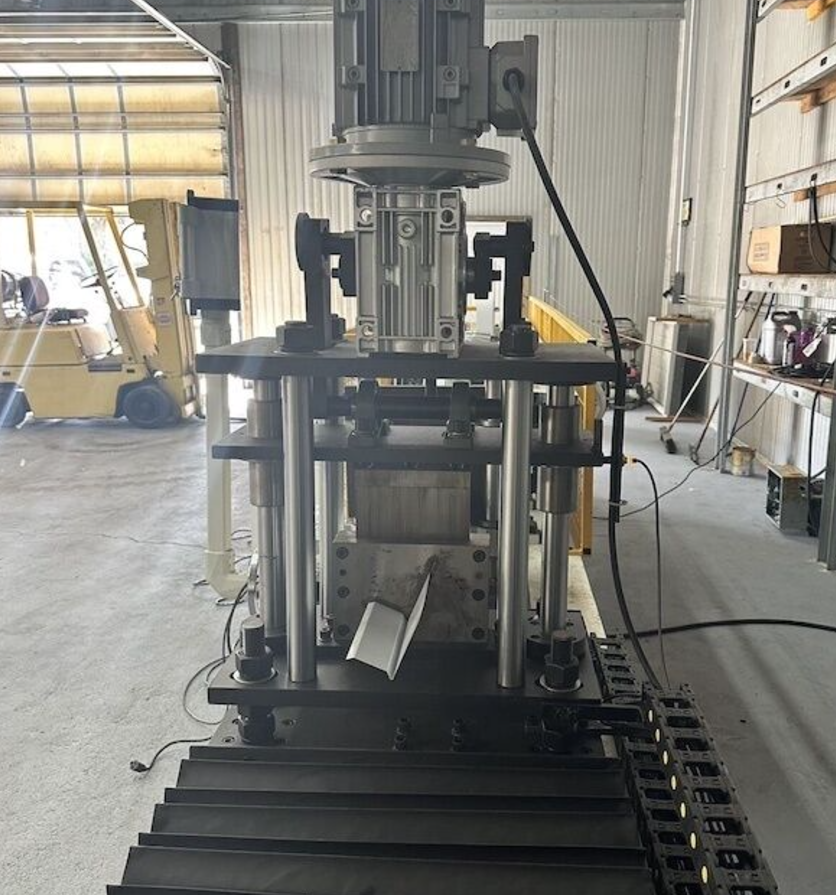

The Fascia Drip Edge Roll Forming Machine is a highly specialized piece of equipment used to produce fascia drip edge profiles, which are essential for roofing systems. These profiles enhance the aesthetics and functionality of buildings by ensuring proper water runoff while protecting fascia boards and roof edges from damage. The machine is designed to create high-quality, consistent profiles suitable for commercial and residential construction projects in Florida, where extreme weather conditions demand durable roofing solutions.

| Feature | Specification |

|---|---|

| Roller Material | High-grade chromium steel (hardened and polished) for long-lasting performance. |

| Frame Size | Heavy-duty steel frame, typically 300–450mm thickness, ensuring stability. |

| Motors | Energy-efficient motors with power ranging from 5.5 kW to 7.5 kW. |

| Hydraulic Cutting System | High-precision hydraulic cutter with hardened steel blades for clean cuts. |

| Punching System | Optional punching and notching system for customizations like nail slots. |

| Speed | Production speed of up to 30–50m/min depending on profile complexity. |

| Control System | PLC (Programmable Logic Controller) with touchscreen interface for automation. |

| Material Thickness | Capable of processing materials ranging from 0.3mm to 0.8mm thickness. |

| Material Types | Galvanized steel, aluminum, copper, or coated sheets. |

| Safety Features | Safety guards, emergency stops, and enclosures for operator protection. |

| Profile Width | Customizable to fit specific fascia drip edge dimensions, typically 50–150mm. |

| Optional Add-Ons | Coil car tippers, automatic stackers, and remote PLC control systems. |

Yes, the machine can process aluminum sheets, making it ideal for lightweight and corrosion-resistant profiles.

Delivery times typically range from 6–12 weeks, depending on customization and shipping arrangements.

Yes, the profiles produced can be customized to meet Florida’s roofing standards and codes.

Absolutely. The machine can be equipped with an optional punching and notching system for added functionality.

The machine requires a workspace of approximately 15–20 feet, including material feeding and output areas.

Most manufacturers offer a one-year warranty covering parts and labor. Extended warranties may be available.

The motors are designed for energy efficiency, ensuring low operational costs while maintaining high performance.

Copyright 2026 © Machine Matcher.