To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

Premium-Condition Line | G-Frame Production | EUR 39,000

This Roll Forming Machine for Galvanized Pocket Filter Frames is a highly specialized and fully operational production line, meticulously engineered for manufacturing galvanized steel frames used in pocket filters. It is ideal for HVAC filter manufacturers and industrial filter frame producers who require high-precision forming, durability, and consistent output for G-profile frames.

This system is offered in top working condition, having undergone a partial overhaul to ensure longevity and performance. It comes with a six-month warranty, providing added confidence and peace of mind for buyers. At a competitive price of EUR 39,000 (excluding VAT), this roll forming machine delivers exceptional value for businesses seeking high output, reliability, and reduced downtime.

NOTE: Price excludes handling and shipping.

Fully functional and in top condition

Partially overhauled for optimal performance

Six-month warranty

Tailored for galvanized G-profile frame production

High production output with precise forming

Includes tooling, cut-off units, lubrication, and control system

This roll forming line has been configured to deliver efficient, high-speed production of galvanized pocket filter frames using G-profiles. Here is an overview of its major specifications and included components:

ENTRY SECTION

This section handles the raw material input and prepares the coil for forming. It includes a single uncoiler capable of handling coils up to 800 kg, with integrated double precutting of strip edges to ensure clean processing and avoid burrs at the V-cutouts.

Entry Material (Coil) Parameters:

Max Coil Width: 100 mm

Max Thickness: 0.8 mm

Material Type: Galvanized Steel

Max Coil Weight: 800 kg

Inner Coil Diameter: 480 – 520 mm

Outer Coil Diameter: Max. 1200 mm

This setup ensures smooth feeding, precise material handling, and minimizes error in downstream forming processes.

The machine is engineered specifically for the production of G-profile frames—commonly used in pocket filters for HVAC systems. The produced profiles are known for their strength, light weight, and compatibility with modern air filter standards.

Profile Type: G-profile

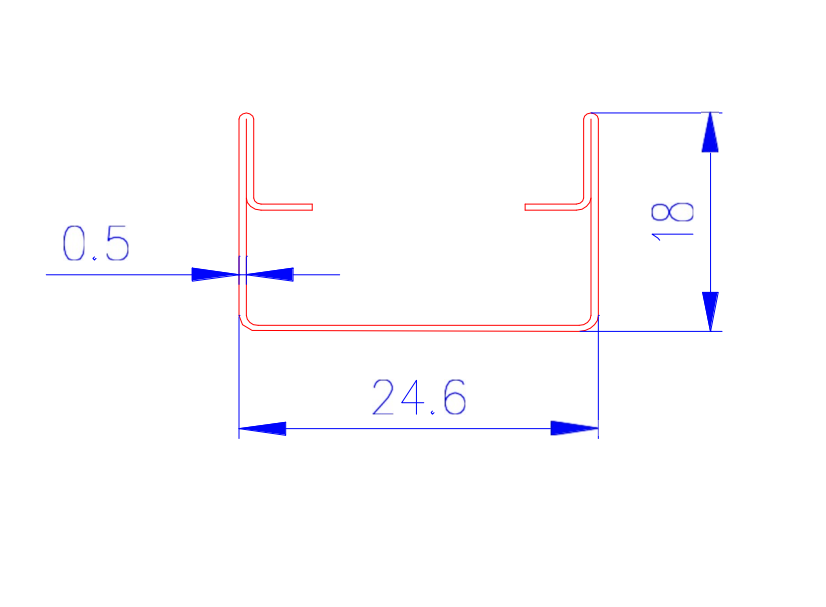

Profile Dimensions (W x H x Thickness): 24.6 mm x 18 mm x 0.5 mm

Rivet Holes per Frame: 1

Production Length Range: 1100 mm – 4000 mm

These parameters make the system versatile for a variety of frame sizes and configurations, ideal for both standard and custom-sized pocket filters.

The heart of the machine—the forming section—has been designed with 11 forming positions, each meticulously aligned for consistent shape and material flow. The section includes gearboxes, a straightening head, and precision drives to maintain forming integrity across extended production runs.

Key Features:

Forming Tables

Straightening Rolls

Gearboxes + Drive (11 Stations)

Automatic Micro Lubrication System

Uses evaporating emulsion for clean and efficient lubrication

11 Forming Stands

Straightening Head (1x)

Electrical System: Includes cabling, drives, frequency converters, control units, and user interface software

This configuration supports reliable long-term production, reducing wear on rollers and ensuring minimal profile deviation.

This section includes two flying V-shape cutout units, synchronized for on-the-fly trimming and high-speed output. A pneumatic run-out table throws finished frames directly into collection bins or boxes for streamlined packaging and assembly.

Cutting and Run-Out Highlights:

2x Flying V-Shape Cut-Out Units

Precision V-cutting at production speed

Run-Out Table with Pneumatic Ejection

Efficient sorting and stacking of completed frames

A complete set of tooling for G-frame profile production is included with the machine. This ensures that the buyer can begin manufacturing immediately upon installation without the need for additional tooling investment.

Max Forming Speed: 15 meters/min

Production Rate for 592 x 592 mm Frame: Up to 4 pcs/min*

Length Tolerance: ±1.0 mm for standard-sized frame (592 x 592 mm)

This line is optimized for mass production of air filter frames with consistent output and high repeatability. Operators can expect tight length tolerance and stable throughput, making it suitable for demanding production environments.

Understanding the footprint and environmental conditions is essential for integrating this machine into an existing facility:

Machine Length: ~20 meters

Machine Width: ~3.5 meters

Machine Height: ~3.0 meters

Profile Axis Height from Ground: 1100 mm

Machine Weight: ~8 tons

Required Operating Temperatures:

During Production: +10°C to +40°C

During Shutdown: 0°C to +50°C

These parameters ensure flexibility for a range of production environments across Europe, the Middle East, and beyond.

Total Installed Power Input: ~20 kW

Power supply specifications should be confirmed before installation to ensure compatibility with local infrastructure.

Machine Price: EUR 39,000

Excluding VAT, Handling & Shipping

Warranty: 6 months from date of delivery or commissioning

This is an exceptional value for a high-precision, low-maintenance forming line tailored to one of the most widely used HVAC filter frame profiles.

This machine is ideal for:

HVAC filter manufacturers

OEMs and contract manufacturers of air filtration systems

Workshops expanding into filter frame production

Metal forming businesses looking for specialized G-profile forming

It’s particularly suitable for companies targeting industrial air filtration, cleanroom environments, commercial HVAC systems, and custom filter fabrications.

Ready-to-run: Immediately operable with minimal setup required

High precision: Accurate forming and V-cutting capabilities

Complete line: Includes uncoiler, forming unit, flying cutter, tooling, controls

Reliable: Built to endure high-volume industrial use

Compact footprint: Despite its full capabilities, the machine fits within standard factory spaces

Cost-effective: Priced competitively vs. new units, with warranty assurance

Machine Matcher connects industrial buyers with high-quality machinery around the world. This roll forming line is backed by industry experience and technical expertise.

Need help with inspection, installation, or logistics? We offer:

International shipping coordination

On-site setup and commissioning

Spare parts sourcing

Remote and on-site training

Copyright 2026 © Machine Matcher.