To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

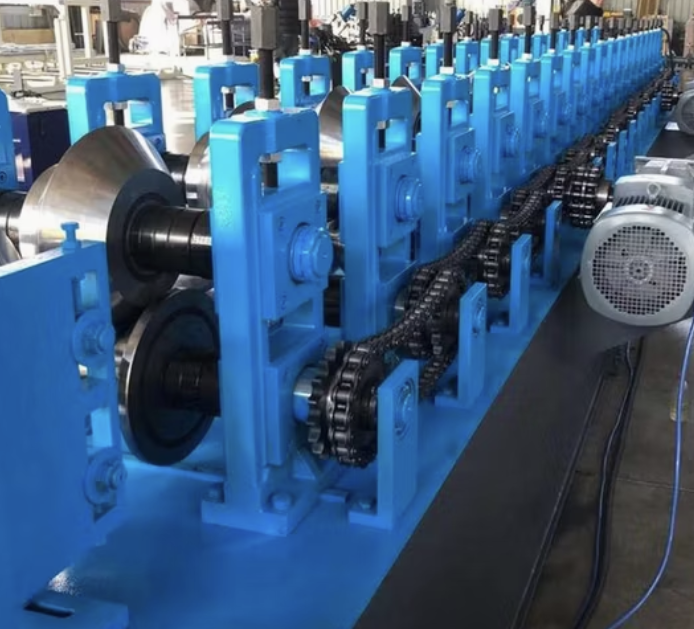

A Flashing Roll Forming Machine is a specialized piece of equipment designed to produce various types of flashing used in construction and roofing projects. Flashings are essential for sealing and directing water away from critical building areas like roof edges, chimneys, and skylights. This machine offers high precision, efficiency, and durability for manufacturers in the roofing and building industry.

A flashing roll forming machine fabricates metal flashing profiles by progressively bending metal sheets or coils into desired shapes. These machines are versatile and can handle a variety of materials, including galvanized steel, aluminum, and pre-painted steel. Flashing roll forming machines are equipped with advanced automation systems, ensuring consistent production quality and minimal material wastage.

Flashing roll forming machines are widely used in industries such as:

Q1: What materials can the flashing roll forming machine handle?

A: It can process galvanized steel, aluminum, stainless steel, copper, and pre-painted steel with a thickness of 0.3 mm to 1.2 mm.

Q2: What is the maximum production speed?

A: The machine can produce profiles at a speed of 20–30 meters per minute, depending on the profile complexity.

Q3: Can the machine produce custom flashing profiles?

A: Yes, the machine is customizable and can produce various flashing shapes, including drip edges, step flashings, and valley flashings.

Q4: What type of cutting system is used in the machine?

A: The machine uses a hydraulic or servo motor-driven cutting system for precision and durability.

Q5: Is the machine suitable for small-scale operations?

A: While designed for high efficiency, the machine can be adjusted for lower production volumes, making it suitable for both small and large-scale operations.

Q6: What is the average maintenance requirement?

A: Regular cleaning, lubrication, and periodic inspections ensure optimal performance and longevity.

Q7: Are there any additional components available?

A: Yes, optional extras include stackers, remote PLC systems, uncoilers, and automatic leveling systems.

A flashing roll forming machine is an essential investment for manufacturers aiming to meet the growing demand for high-quality construction flashings in the USA. Its precision, speed, and versatility make it a valuable tool for roofing and construction projects.

Copyright 2026 © Machine Matcher.