To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

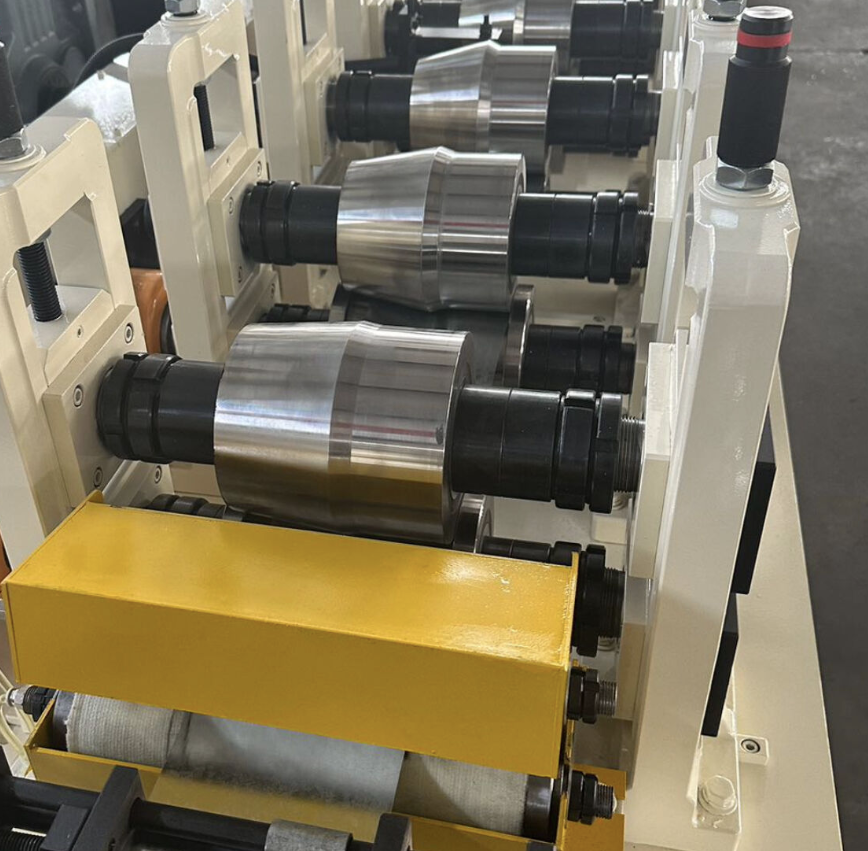

GALV DRIP EDGE 2” X 2” ROLL FORMING MACHINE - CALIFORNIA, USA

The GALV DRIP EDGE 2” X 2” Roll Forming Machine is designed for precision manufacturing of galvanized drip edge profiles used in residential and commercial roofing systems. This high-speed, durable, and efficient machine is built to meet the rigorous demands of metal fabrication businesses, roofing contractors, and construction material manufacturers across California and beyond.

With a robust electric shear, 80 ft/min production speed, and 10 forming stands, this roll forming machine ensures seamless and consistent output. The machine is custom-built to match specific profile requirements and shipped directly from our manufacturing partner to the customer’s location.

Our roll forming machine supports a variety of drip edge profiles and sizes, ensuring versatility for different roofing applications.

The GALV DRIP EDGE 2” X 2” Roll Forming Machine is primarily used in:

All machines are new and custom-built to meet customer-specific profile and machine requirements. This machine will be shipped directly from our manufacturing partner to the customer’s location in California, USA.

Machine Matcher supplies customers worldwide with a wide range of roll forming equipment, including:

We also provide full service support including machine sales, maintenance, repairs, setup, and adjustments.

If you have profile drawings or specific machine requirements, send your details to [email protected] to receive a customized quote.

Q: What is the power requirement for this machine?

A: The machine operates on 240V three-phase, 60 Hz, which is standard for industrial applications in the USA.

Q: Can this machine produce custom drip edge profiles?

A: Yes, we can customize the roll forming machine to produce specific profiles based on your requirements.

Q: What is the production speed of this machine?

A: This machine operates at a high speed of 80 feet per minute, ensuring efficient production.

Q: What materials can this machine process?

A: The machine is designed to work with aluminum, galvanized steel, and copper, covering a wide range of industry applications.

Q: Does the machine come with a warranty?

A: Yes, all our machines come with a one-year warranty from the dispatch date, along with ongoing maintenance and repair support.

Q: How do I get a quote?

A: You can email your profile drawings or specific requirements to [email protected], and we will provide a tailored quote.

Q: Can Machine Matcher assist with machine setup and maintenance?

A: Yes, we offer full service support including machine sales, setup, adjustments, repairs, and maintenance.

For more details, contact us today and let us help you find the perfect roll forming solution for your business!

Copyright 2026 © Machine Matcher.