To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

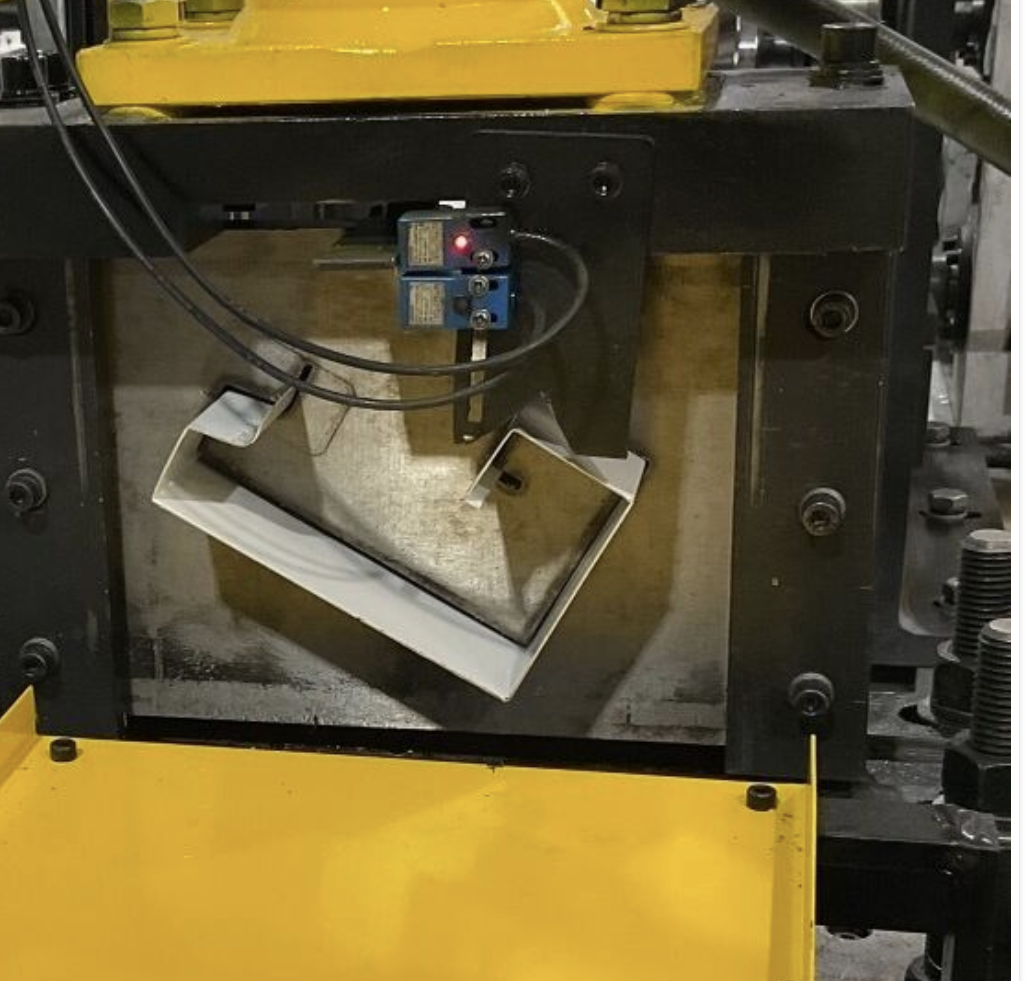

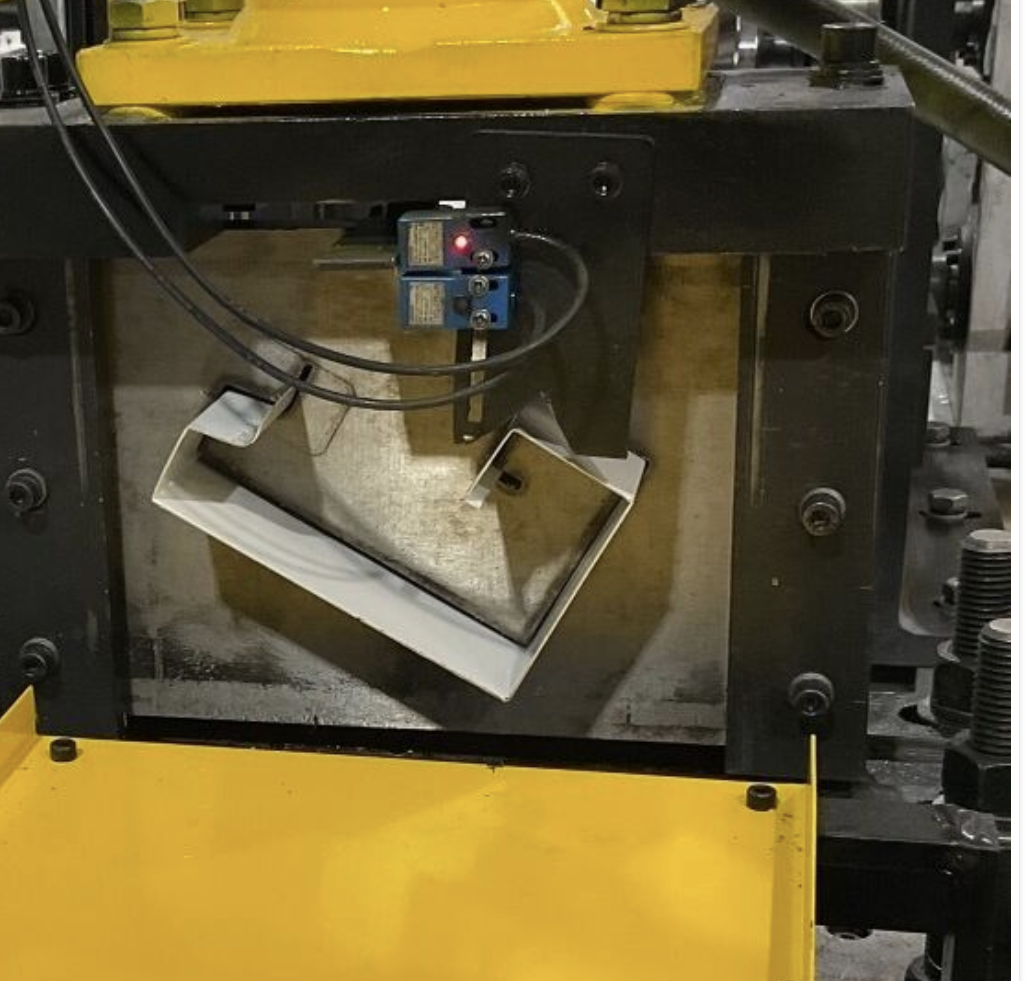

A gutter roll forming machine is specialized equipment used to produce seamless gutters for residential, commercial, and industrial applications. These machines offer precision, efficiency, and customization, making them essential for businesses in the roofing and gutter industry. In the USA, where seamless gutters are in high demand, these machines cater to a growing need for durable and aesthetically appealing drainage systems.

The gutter roll forming machine is designed to create continuous lengths of metal gutters in a variety of profiles, such as K-style and half-round. It uses advanced roll forming technology to transform coiled metal sheets into finished gutter products with consistent quality and accuracy.

Below are the standard specifications commonly offered for gutter roll forming machines in the USA:

Q1. What types of gutters can be produced with this machine?

A: Gutter roll forming machines can produce K-style, half-round, and box gutters in varying sizes, such as 5-inch and 6-inch, which are popular in the USA.

Q2. Is this machine suitable for aluminum gutters?

A: Yes, it works perfectly with aluminum, galvanized steel, copper, and other materials commonly used for gutters.

Q3. Can I produce multiple profiles with one machine?

A: Yes, many models come with adjustable rollers or interchangeable cassettes to switch between profiles like K-style and half-round.

Q4. How fast can the machine operate?

A: Standard models operate at speeds of 10–15 meters per minute, while high-speed versions can reach up to 20 meters per minute.

Q5. What are the power requirements for USA operations?

A: Most machines are compatible with 220V/60Hz or 480V/60Hz, 3-phase power supplies, adhering to USA standards.

Q6. Do I need additional equipment for the machine?

A: Optional equipment includes decoilers, stackers, coil cars, and in-line punching systems, depending on your production needs.

Q7. What is the price range for a gutter roll forming machine?

A: Prices range from $30,000 to $95,000, depending on the machine’s specifications and optional features.

Q8. What is the lifespan of a gutter roll forming machine?

A: With proper maintenance, a high-quality machine can last over 10 years.

A gutter roll forming machine is an essential investment for businesses in the USA's roofing and gutter industry. With its versatility, precision, and efficiency, this machine enables seamless gutter production, meeting diverse market demands. Whether you need a standard or high-speed model, selecting the right machine can streamline your operations and enhance profitability.

Copyright 2026 © Machine Matcher.