To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

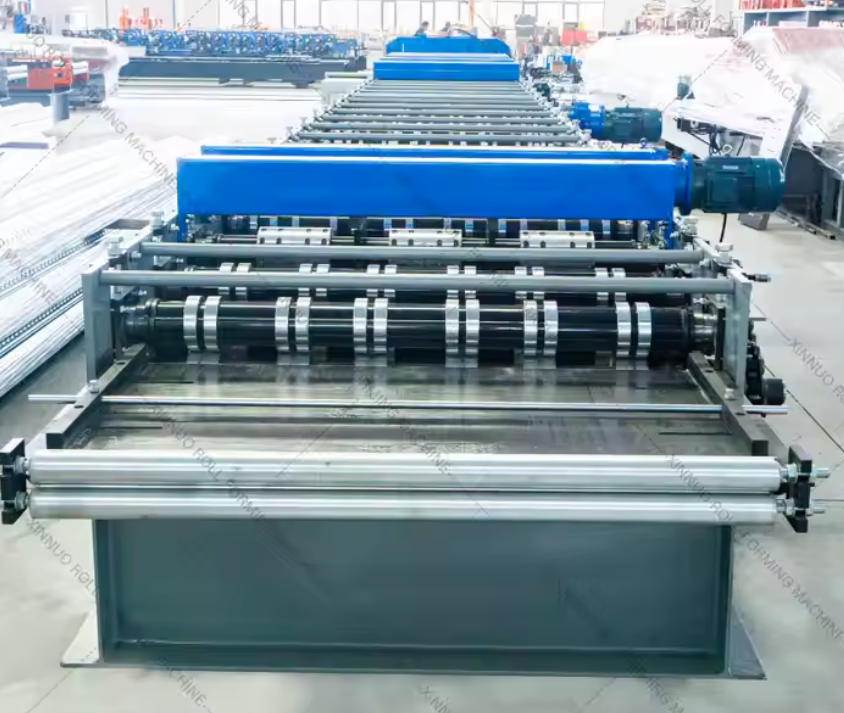

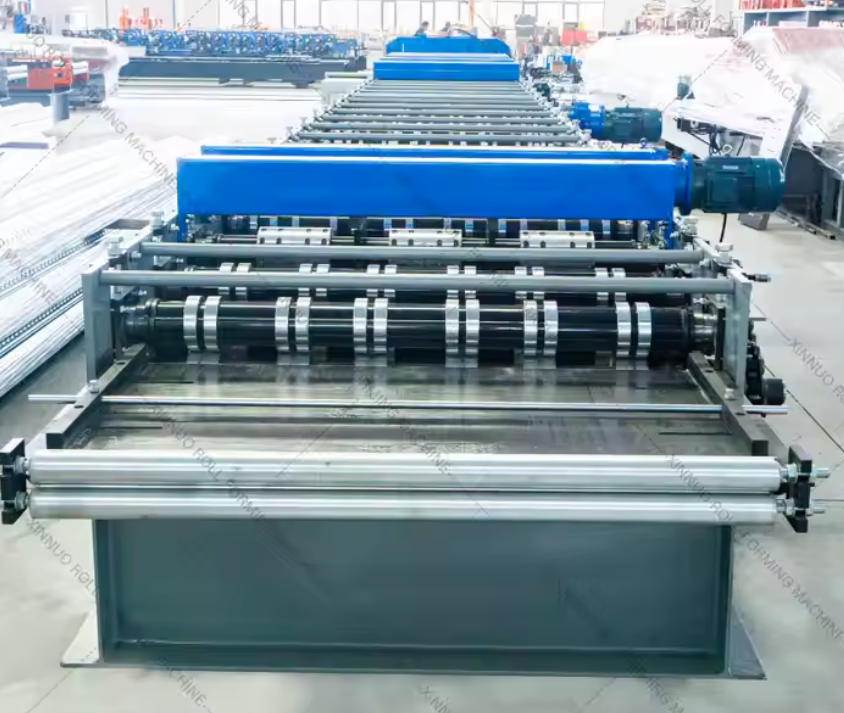

Heavy-Duty Composite Floor Deck Roll Forming Machine – UAE Market Edition

Engineered for strength. Built for the future. Delivered across the United Arab Emirates.

The Heavy-Duty Composite Floor Deck Roll Forming Machine is a precision-engineered solution designed to produce high-strength, load-bearing steel composite floor decking systems widely used in large-scale commercial, industrial, and infrastructure projects across the UAE. Designed for structural integrity and efficiency, this machine is capable of handling thicker gauge materials and higher tensile strength steel, meeting the demanding standards of UAE’s modern construction sector.

From Dubai skyscrapers to Abu Dhabi commercial hubs and Sharjah industrial zones, this machine is ideal for manufacturing composite floor deck panels used in concrete-steel composite slabs that support heavy structural loads. It supports fast on-site construction, improves slab performance, and reduces the need for traditional reinforcement.

All machines are new, custom-built, and delivered directly to your UAE location by Machine Matcher’s global partners.

Commercial Building Construction

Infrastructure Development (Airports, Bridges, Tunnels)

Industrial Facilities & Warehouses

High-Rise Residential Towers

Pre-Engineered Building (PEB) Fabrication

Steel Structure Projects across UAE

| Specification | Details |

|---|---|

| Machine Type: | Heavy-Duty Composite Floor Deck Roll Forming Machine |

| Production Speed: | 15–25 meters/min (depending on profile and material) |

| Material Thickness Range: | 0.8mm – 1.5mm |

| Material Width Range: | 1000mm – 1300mm |

| Material Types: | Galvanized Steel (GI), Galvalume (GL), Cold Rolled Steel (CR), High-Tensile Steel |

| Material Yield Strength: | Up to 550 MPa |

| Roller Material: | GCr15 (high-grade bearing steel) |

| Roller Surface Treatment: | Hard chrome plating for corrosion resistance |

| Number of Forming Stations: | 20–26 stations (depending on profile depth and design) |

| Roller Shaft Diameter: | 75mm–95mm |

| Shaft Material: | High-strength 40Cr |

| Main Drive Type: | Gearbox drive system for heavy-duty performance |

| Power (UAE Standard): | 380V / 50Hz / 3 Phase |

| Motor Power: | 22kW–30kW (customizable based on profile) |

| Cutting Method: | Hydraulic cutting system |

| Blade Material: | Cr12Mov (heat-treated high-strength tool steel) |

| Control Type: | PLC automatic control (Siemens/Delta) with HMI touchscreen |

| Operating Mode: | Fully automatic with manual override |

| De-coiling System: | Hydraulic uncoiler – 5 Ton or 10 Ton optional |

| Punching/Notching System (if included): | Hydraulic punching system with pre-cut options |

| Machine Frame: | Welded H-Beam steel frame |

| Thickness of Frame Steel: | 20–30mm base plate for vibration resistance |

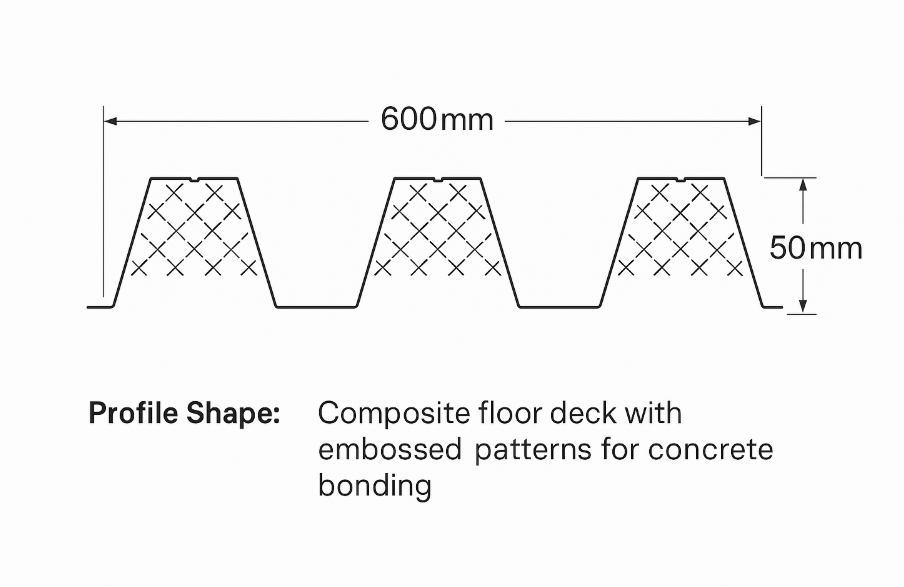

| Profile Shape: | Composite floor deck with embossed patterns for concrete bonding |

| Profile Width and Depth: | Width: 600mm–1000mm / Depth: 50mm–76mm (standard profiles) |

| Length Tolerance: | ±1.5mm |

| Safety Features: | CE-compliant |

| - Full protective covers | |

| - Emergency stop buttons | |

| - Overload protection system |

Prices start from: USD $85,000

(Depending on profile size, punching, uncoiler size, and automation level)

What affects the final price?

Profile complexity and width

Embossing requirements

Level of automation

Type and size of uncoiler

Punching/notching systems

Output speed and motor power

Country-specific electrical and safety customizations

All machines are custom-built and brand new, delivered throughout the UAE including Dubai, Abu Dhabi, Sharjah, Ajman, Fujairah, and Al Ain. Installation support, training, and maintenance services are available.

Warranty: 1 year from dispatch

Support: Full maintenance & parts availability

Remote troubleshooting & operator training available

To receive a tailored quote, please email your profile drawing, required thickness, speed, and power requirements to:

[email protected]

Q1: Can this machine produce custom profile shapes or embossing patterns?

A: Yes. The machine can be designed to match your custom composite floor deck profile and embossing requirements for improved bonding with concrete.

Q2: Is installation and training available in the UAE?

A: Yes. On-site installation and operator training can be arranged throughout the UAE.

Q3: What type of steel coils can be used in this machine?

A: The machine supports galvanized steel, galvalume, and high-tensile steel coils with yield strength up to 550 MPa.

Q4: Can this machine be connected to a coil handling system or stacker?

A: Yes. Optional extras such as automatic stackers, coil cars, hydraulic uncoilers, and leveling systems can be integrated based on your production needs.

Q5: How long is the delivery time to the UAE?

A: Average delivery time is 45–75 days after order confirmation, depending on machine complexity and shipping schedule.

Q6: Is remote technical support available?

A: Yes. Remote diagnostics, setup guidance, and troubleshooting are part of our after-sales support package.

Machine Matcher connects you with globally trusted manufacturers of heavy-duty roll forming machines, ensuring you get the right equipment at competitive pricing—customized to your UAE standards, delivered with expert advice, and backed by full after-sales support.

Get Started Today.

Email your profile drawing and requirements to [email protected] and receive a competitive quote from our expert team.

All machines are new, built to your exact specifications, and delivered directly to your location in the UAE.

Copyright 2026 © Machine Matcher.