To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

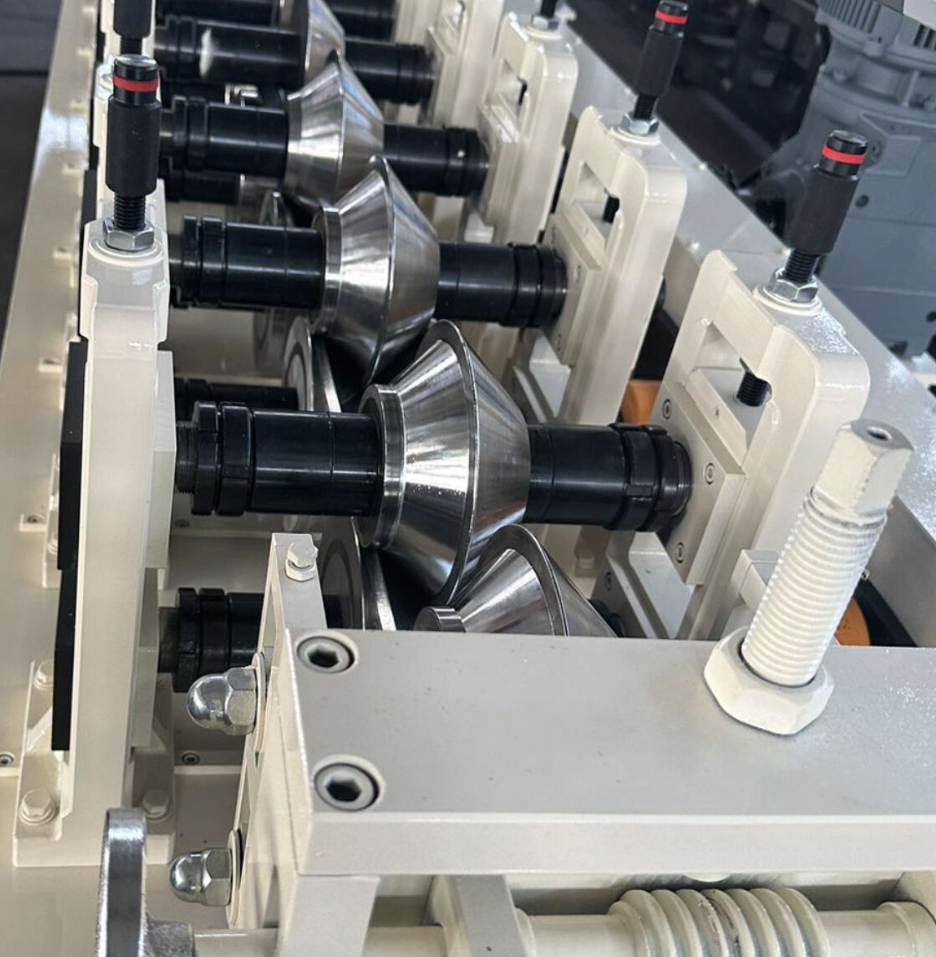

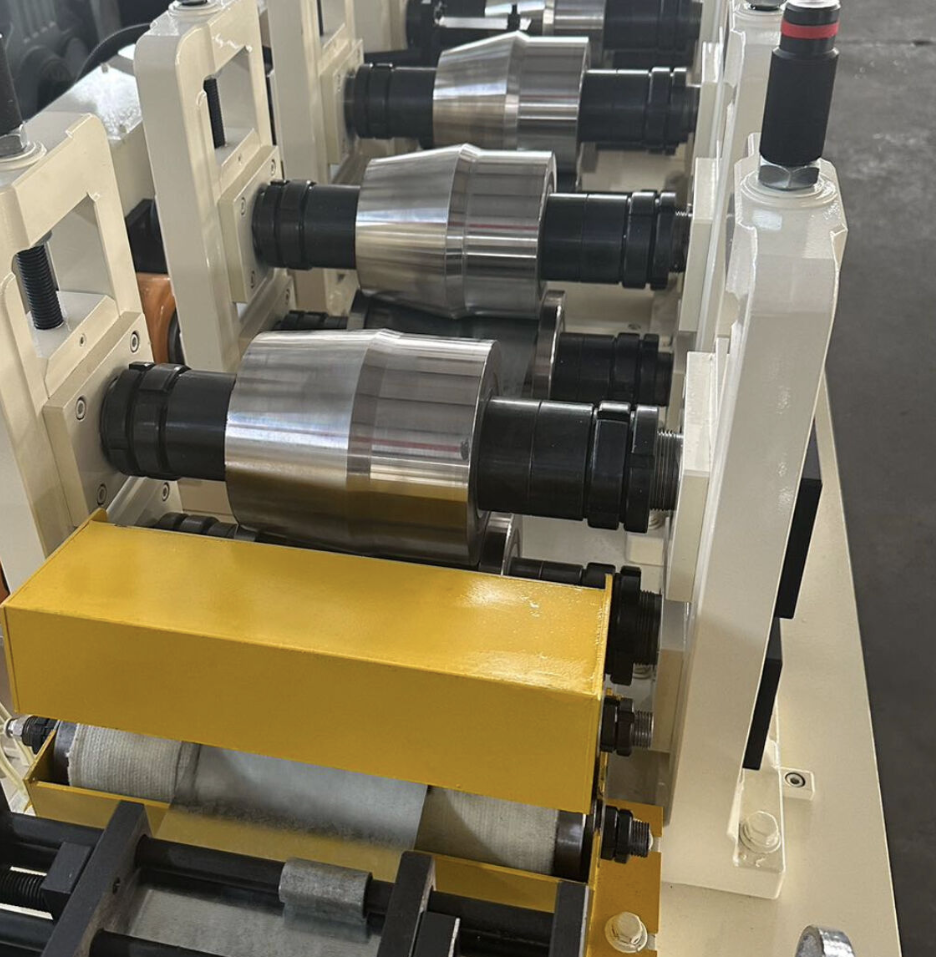

The high-speed drip edge cold roll forming machine is designed to efficiently produce drip edges used in roofing systems. These drip edges prevent water from penetrating beneath the roofing structure, ensuring durability and protection. This machine is ideal for contractors, manufacturers, and suppliers in the construction industry, particularly in Florida, where roofing is a critical component due to the state's weather conditions.

The machine features advanced technology to produce precise, consistent profiles at high speeds. Its compact design ensures easy installation and operation, while its automated system minimizes manual intervention, increasing productivity and reducing operational costs.

Q1: What industries in Florida benefit from the high-speed drip edge roll forming machine?

A1: Roofing contractors, construction companies, and metal product manufacturers in Florida widely use this machine to produce drip edges for residential, commercial, and industrial projects.

Q2: Can the machine handle different materials?

A2: Yes, it supports materials like aluminum, galvanized steel, stainless steel, and copper, making it versatile for various projects in Florida.

Q3: How fast can the machine produce drip edge profiles?

A3: The machine operates at speeds of up to 45 meters per minute, depending on the profile complexity and material thickness.

Q4: Is the machine compatible with Florida’s power supply standards?

A4: Yes, the machine’s power supply can be customized to match Florida’s standard voltage and frequency requirements.

Q5: What maintenance is required for the machine?

A5: Regular maintenance includes lubrication of moving parts, inspection of rollers and cutting systems, and software updates for the PLC system.

Q6: Can the machine’s output size be adjusted?

A6: Yes, the machine is highly customizable, allowing adjustments to profile width and thickness to meet specific project requirements.

Q7: Are optional features available for this machine?

A7: Yes, optional extras like automatic stackers, remote PLC systems, and advanced coil handling equipment can be added to enhance efficiency.

Q8: What is the delivery time for the machine in Florida?

A8: Delivery typically takes 6–8 weeks, depending on the customization level and shipping logistics.

Q9: Does the machine come with installation support?

A9: Yes, manufacturers provide installation assistance and training to ensure smooth operation.

Q10: How can I ensure compliance with Florida’s building standards?

A10: The machine’s precision ensures profiles meet Florida’s stringent roofing standards. Additionally, manufacturers can provide certifications for material compliance.

Copyright 2026 © Machine Matcher.