To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

|

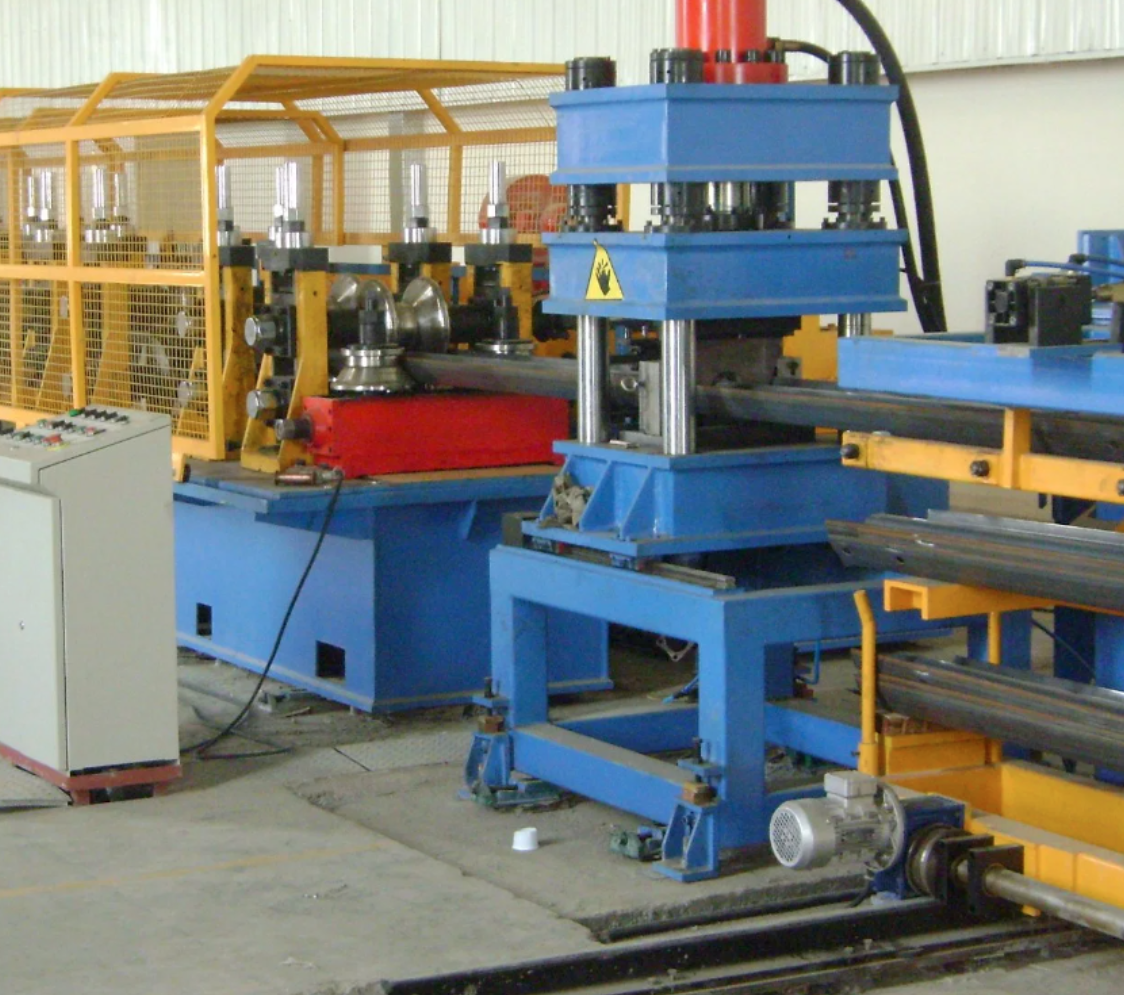

Material: |

Cold rolled mild steel |

|

Raw material yield strength |

235 Mpa |

|

Tensile strength of raw materials |

550 Mpa |

|

Coils OD |

1600 mm |

|

Coils ID |

508mm |

|

Strips width |

750mm |

|

Strips thickness |

2.3~4mm |

|

Coils weight |

7000 kg |

|

Line speed |

4 pcs/min(for sample Length 4320mm) |

As Saudi Arabia continues to invest in its infrastructure, the demand for durable, high-quality highway guardrails has never been greater. Highway guardrails play a crucial role in road safety, protecting drivers and pedestrians from accidents and vehicle runoff. To meet this demand, roll forming machines have become indispensable in the manufacturing process. Here’s an in-depth look at how roll forming technology is shaping the production of highway guardrails in Saudi Arabia.

Highway guardrails are essential safety features designed to prevent vehicles from veering off the road and into dangerous areas, such as steep embankments or oncoming traffic. With the increasing number of vehicles on Saudi Arabia’s roads and the expansion of highway networks, ensuring that these safety features are both effective and reliable is critical.

The rapid expansion of Saudi Arabia's infrastructure, including new highways and urban development projects, has led to a surge in demand for highway guardrails. Roll forming machines are well-positioned to meet this demand due to their efficiency, precision, and adaptability.

Manufacturers in Saudi Arabia can benefit from investing in advanced roll forming technology that not only meets local safety regulations but also enhances production capabilities. Collaborating with local contractors and suppliers can further improve supply chain efficiency, ensuring that guardrails are available where and when they are needed.

As technology advances, the future of guardrail production will likely incorporate even more automation and innovative manufacturing techniques. Smart manufacturing, utilizing IoT and data analytics, could optimize production processes, further increasing efficiency and reducing costs.

Additionally, as sustainability becomes a key focus in construction and manufacturing, the use of recycled materials in guardrail production may gain traction, aligning with global environmental standards.

Roll forming machines are revolutionizing the way highway guardrails are produced in Saudi Arabia. Their ability to deliver high-quality, durable products at scale makes them an essential tool for manufacturers looking to support the country's ambitious infrastructure goals. By embracing advanced roll forming technology, Saudi Arabia can ensure its highways are equipped with the safety features necessary to protect its drivers and promote safe travel for all.

Investing in roll forming machines not only enhances production capabilities but also contributes to the overall safety and efficiency of the country’s expanding transportation network.

Copyright 2026 © Machine Matcher.