To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

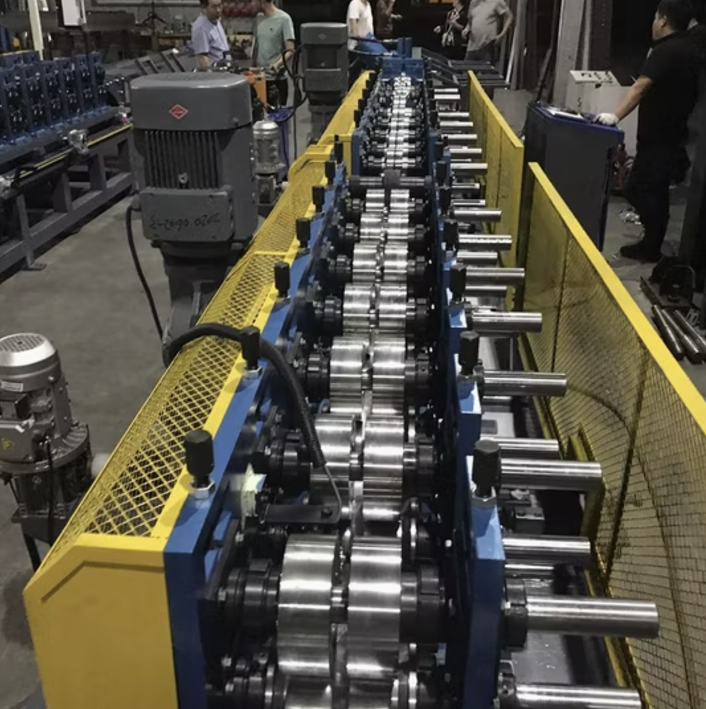

A J Channel Metal Siding Roll Forming Machine is a specialized equipment designed to produce high-quality J-channel profiles used in siding applications. These profiles are widely utilized in residential, commercial, and industrial construction for securing siding edges and providing a clean, finished look to buildings. The machine is designed for high-speed, precision manufacturing and can handle a variety of materials to meet the needs of the construction industry in the USA.

Here are the detailed specifications for a J Channel Metal Siding Roll Forming Machine:

The J Channel Metal Siding Roll Forming Machine is engineered for efficiency, precision, and reliability. It transforms metal coils into finished J-channel profiles through a series of rollers that shape, cut, and punch the metal to exact specifications. This machine is essential for manufacturers in the siding and construction industries, as it can produce large volumes of J-channels with consistent quality and minimal waste.

The USA market prioritizes durable and high-performance machines, and this roll forming machine meets those expectations. Its robust construction, advanced PLC control, and hydraulic cutting systems ensure precision in every profile. Whether used for small-scale production or high-volume manufacturing, this machine adapts to various operational needs.

Q1: What materials can the J Channel Metal Siding Roll Forming Machine process?

A: The machine can process galvanized steel, aluminum, and stainless steel, with a thickness range of 0.3-1.2mm.

Q2: Can the machine handle custom profile designs?

A: Yes, the rollers and punching systems can be customized to produce various J-channel designs.

Q3: What is the average production speed of the machine?

A: The machine can produce profiles at a speed of 10-20 meters per minute, depending on the complexity of the profile.

Q4: Is it possible to integrate an automatic stacker with the machine?

A: Yes, an automatic stacker is available as an optional add-on for efficient stacking of finished profiles.

Q5: How is the machine controlled?

A: The machine uses a PLC system with a touchscreen interface, which allows for precise control and easy programming of production parameters.

Q6: What safety features does the machine have?

A: Safety covers, emergency stop buttons, and overload protection are included to ensure safe operation.

Q7: Can this machine handle heavy-duty production?

A: Yes, its heavy-duty frame and robust motor are designed for continuous, high-volume production.

Q8: What is the delivery time for the machine in the USA?

A: Delivery times typically range from 30-60 days, depending on customization and stock availability.

Q9: How much maintenance is required for this machine?

A: Routine maintenance includes lubrication of rollers and motors, inspection of cutting blades, and cleaning of the machine to prevent debris buildup.

Q10: What is the cost range for the J Channel Metal Siding Roll Forming Machine?

A: Prices vary based on specifications and customizations but generally range between $40,000 and $100,000.

Copyright 2026 © Machine Matcher.