To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

| Material | Colored steel sheet, galvanized steel sheet, aluminum sheet |

| Thickness of coil sheet | 1.0-2.0mm |

| Efficiency width | 25/30mm |

| Machine details | |

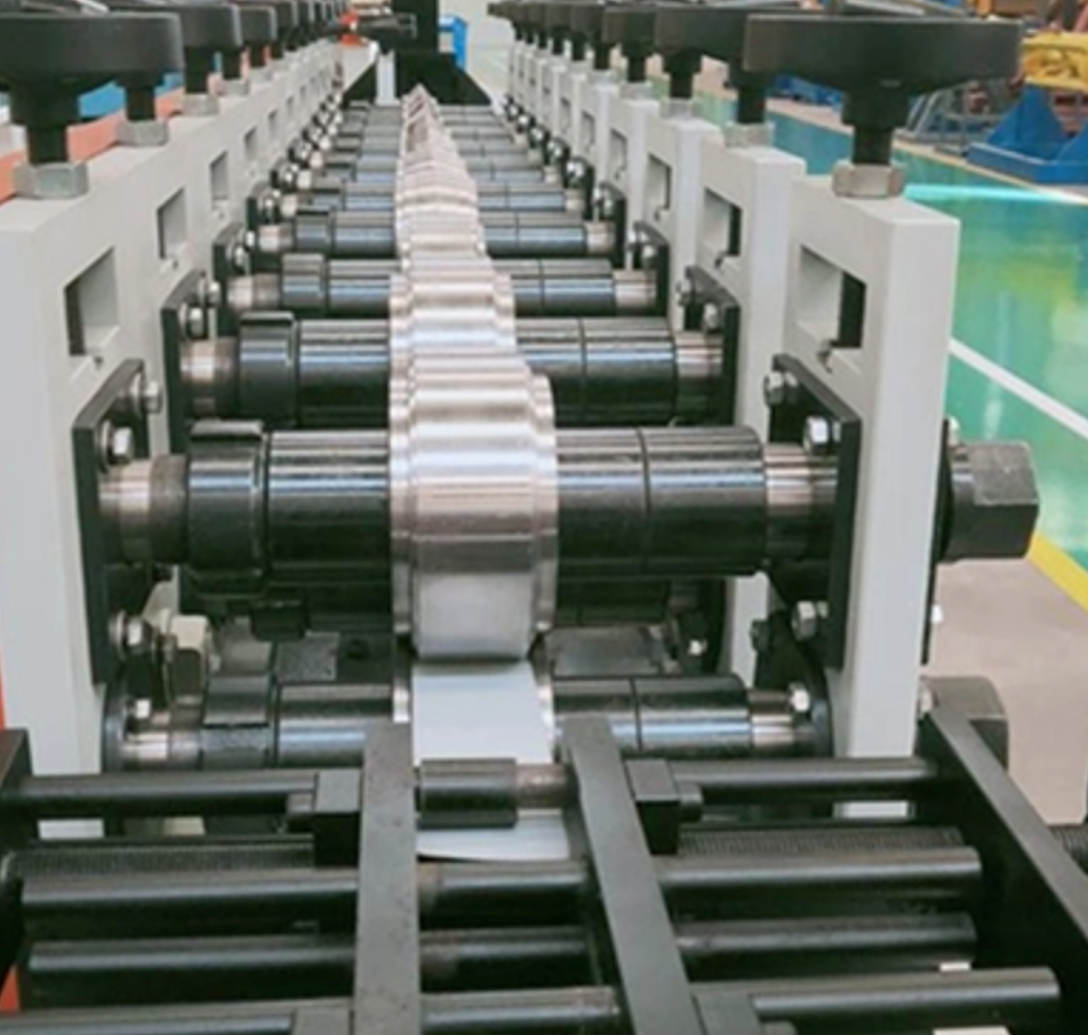

| Roller material | High grade NO. 45 forged steel |

| Shaft material | High grade NO. 45 carbon wrought steel |

| Cutting blade | Cr12 mould steel with quenched treatment |

| Diameter of shaft | 70mm or as your requirement |

| Main frame | 300 H steel |

| Forming steps | 16 stations |

| Productivity | 15-20m/min |

| Hydraulic station power | 4KW |

| Hydraulic pressure | 10-12MPa |

| Appearance size | 7700mm*1500mm*1500mm |

| Hydraulic oil | 40# hydraulic oil |

| Electric tension | 380V 50 Hz 3 Phase or as your requirement |

| Cut Mode | Hydraulic forming after cutting off |

| Cutter material | Cr12 Heat Treatment |

| Electronic control system | PLC, Touch Screen, Encoding counter |

Light gauge roll forming machines are specialized equipment designed for producing lightweight metal profiles and components, typically used in construction, manufacturing, and other industries. These machines are particularly adept at processing thin sheets of steel, aluminum, and other metals to create a variety of profiles, such as studs, tracks, and other structural elements. Here’s a more detailed overview:

Light gauge roll forming machines are essential tools for companies looking to optimize their production processes while maintaining high standards of quality and efficiency in their metal component manufacturing.

Copyright 2026 © Machine Matcher.