To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

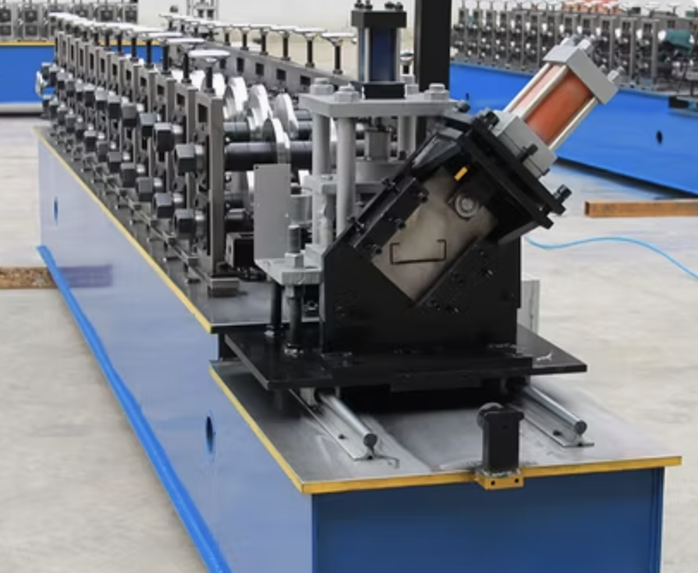

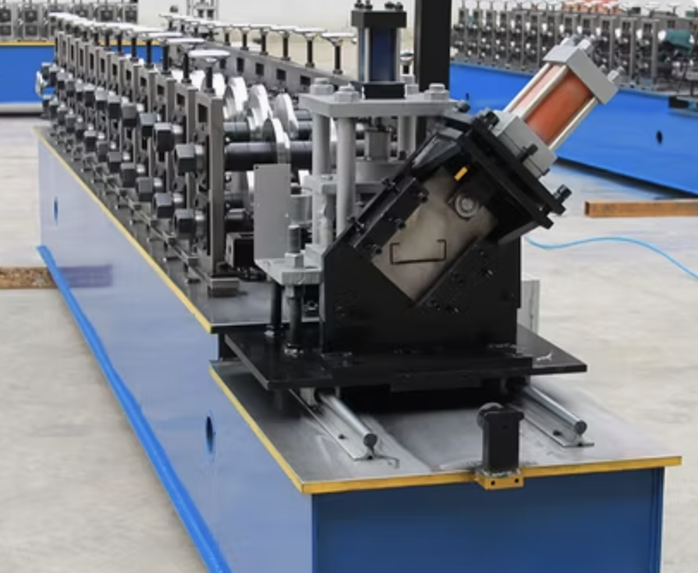

Light gauge roll forming machines are designed to manufacture thin and lightweight metal profiles used in construction, especially for framing, roofing, and partition systems. These machines are essential for producing light steel framing (LSF) components like studs, tracks, and channels, widely used in residential, commercial, and industrial building projects. Known for their precision and efficiency, light gauge roll forming machines offer a reliable solution for mass-producing profiles with consistent quality.

1. Machine Components:

2. Performance:

3. Safety Features:

4. Optional Extras:

Light gauge roll forming machines cater to the construction industry in the UK by providing lightweight, sustainable, and efficient solutions for building frameworks. These machines are integral to:

Q1: What profiles can a light gauge roll forming machine produce?

A: These machines can manufacture various profiles, including C-studs, U-tracks, Z-purlins, and custom shapes, depending on the dies and rollers installed.

Q2: Is the machine compatible with UK power supply standards?

A: Yes, most light gauge roll forming machines are compatible with the UK’s standard 415V, 50Hz, three-phase power supply.

Q3: What material thicknesses are supported?

A: The machine supports material thicknesses from 0.3 mm to 1.2 mm, suitable for light framing applications.

Q4: Can I customize the profiles for specific construction projects?

A: Yes, the machine can be equipped with customizable dies and rollers for project-specific profile designs.

Q5: How much space is required for installation?

A: A typical light gauge roll forming machine requires a floor area of approximately 10–15 meters in length and 2–3 meters in width.

Q6: What are the maintenance requirements?

A: Regular lubrication of moving parts, periodic alignment checks for rollers, and monitoring of the PLC system are essential for maintaining the machine's performance.

Q7: Are training and support available in the UK?

A: Many manufacturers and distributors in the UK provide installation, training, and ongoing support for their machines.

Q8: What is the cost of a light gauge roll forming machine?

A: Prices range from £30,000 to £80,000, depending on machine capabilities, optional features, and production capacity.

Copyright 2026 © Machine Matcher.