To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

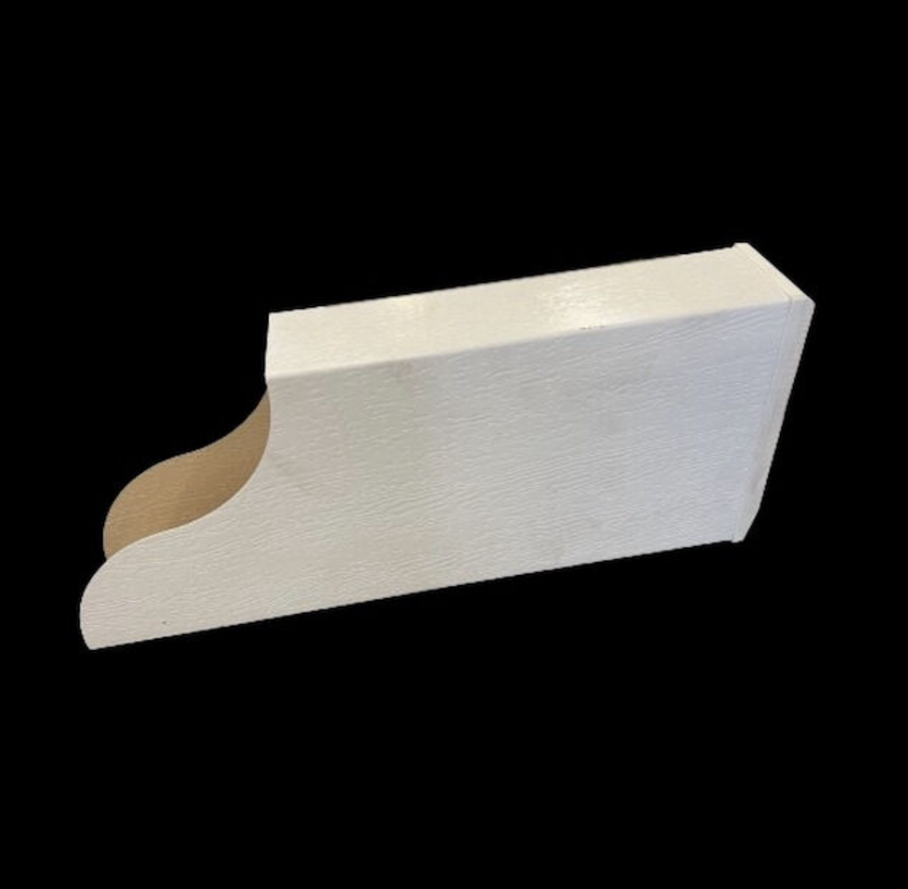

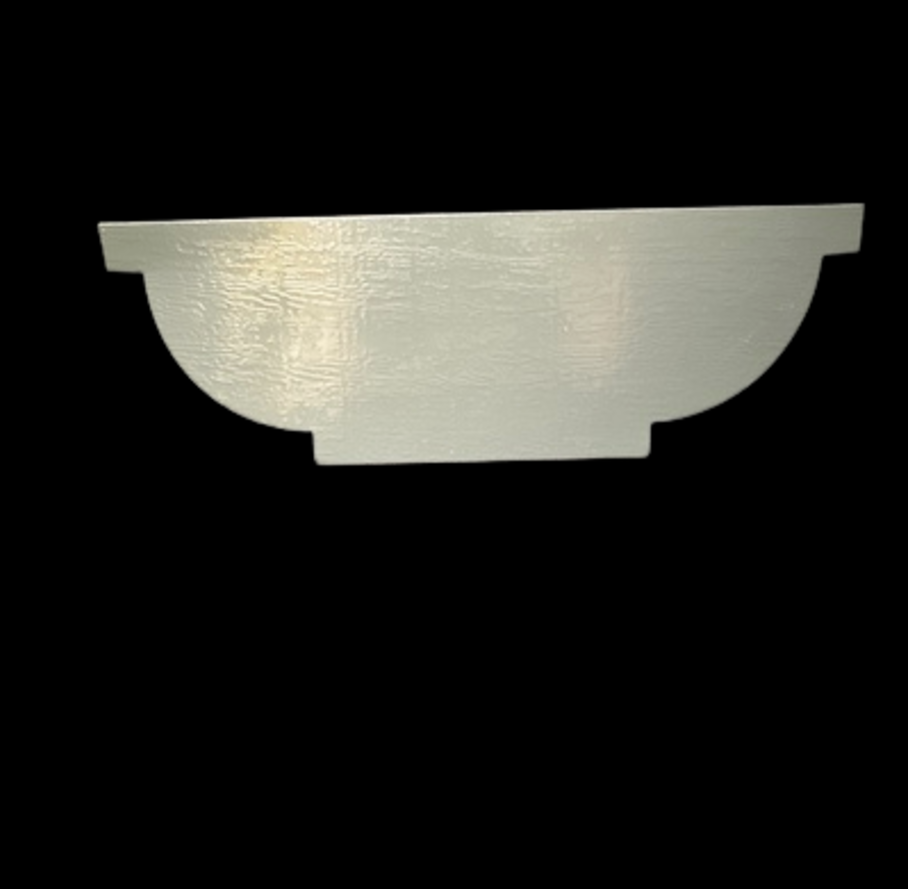

The Metal 3x8 Corbel Cutter Machine is a specialized tool designed to produce precise, intricate corbels for architectural applications. These machines are essential for creating corbels used in both structural and decorative applications, such as supporting overhanging structures, mantels, or shelves. Known for their precision, efficiency, and versatility, these machines cater to the growing demands of Florida's construction and design industry, where custom metalwork is highly valued.

| Specification | Details |

|---|---|

| Material Capability | Steel, Aluminum, Stainless Steel |

| Cutting Dimensions | Up to 3x8 feet per corbel |

| Cutting Mechanism | CNC-controlled precision cutting tools |

| Motor Power | 7.5 HP |

| Accuracy | ±0.1 mm |

| Control System | PLC with touch screen interface |

| Production Speed | 10–15 corbels per hour |

| Safety Features | Emergency stop, safety guards, and enclosures |

| Power Requirements | 220V/380V, 3-phase |

| Weight | Approx. 1,200 kg |

| Machine Dimensions | 4.5 x 3 x 5 feet |

Q1: What materials can the 3x8 Corbel Cutter Machine handle?

A: This machine can handle a variety of metals, including steel, aluminum, and stainless steel, making it versatile for multiple applications.

Q2: Is the machine suitable for a small business in Florida?

A: Yes, its efficient design, user-friendly controls, and compact size make it ideal for both small-scale workshops and larger enterprises.

Q3: Can the machine produce custom corbel designs?

A: Absolutely. The machine features CNC controls that allow for precise customization, accommodating a wide range of designs and dimensions.

Q4: What power supply is needed for operation?

A: The machine requires a 220V/380V, 3-phase power supply, common in commercial and industrial setups in Florida.

Q5: How safe is the machine to operate?

A: The machine includes advanced safety features such as an emergency stop button, safety guards, and enclosures to protect operators during use.

Q6: What is the average production rate?

A: The machine can produce between 10 and 15 corbels per hour, depending on the complexity of the design.

Q7: What maintenance is required?

A: Regular maintenance involves cleaning, lubrication of moving parts, and checking the CNC controls for updates or adjustments.

Q8: Is there local support for repairs and parts in Florida?

A: Yes, several local distributors and service providers in Florida offer support for the machine, ensuring minimal downtime.

Copyright 2026 © Machine Matcher.