To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

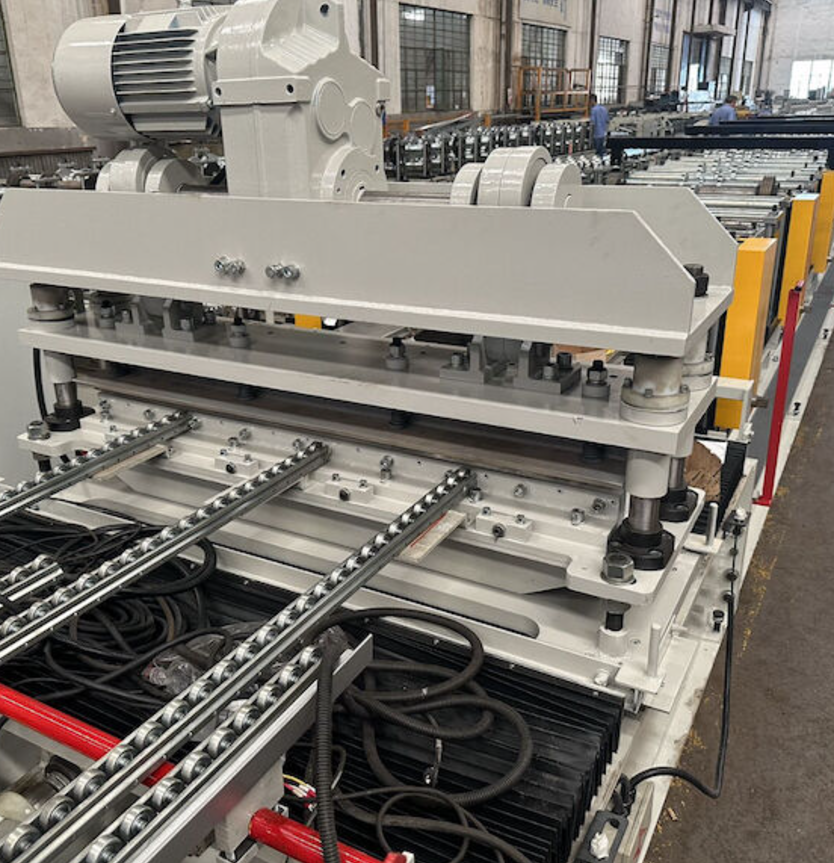

A Metal Deck Roll Forming Machine is a specialized piece of equipment used to produce metal decking profiles commonly used in construction projects for flooring, roofing, and composite slabs. These machines are designed to create durable, high-quality decking with precise dimensions and enhanced structural integrity.

The Oregon construction market, with its focus on sustainable and efficient building practices, benefits significantly from metal deck roll forming machines. These machines provide the capability to produce customized decking profiles, aligning with local requirements and reducing material waste.

Here are the key specifications typically found in a metal deck roll forming machine:

Q1: What types of metal can this machine process?

A: The machine can process galvanized steel, pre-painted steel, aluminum, and other metals, with thicknesses ranging from 0.7 mm to 1.5 mm.

Q2: How customizable are the deck profiles?

A: Highly customizable. The machine can adjust width, rib height, and punching patterns to suit specific project requirements.

Q3: How does it support sustainability in Oregon?

A: By minimizing material waste and allowing local production, it reduces transportation emissions and material loss.

Q4: What is the average production capacity?

A: Depending on the machine, it can produce 15 to 40 meters of metal deck per minute.

Q5: Are these machines compatible with Oregon’s power grid?

A: Yes, machines can be configured for 220V, 380V, or 440V, ensuring compatibility with Oregon's industrial power supply.

Q6: What is the maintenance requirement?

A: Regular lubrication of moving parts, periodic roller alignment checks, and cleaning ensure optimal performance.

The demand for metal decking in Oregon is fueled by its vibrant construction sector, driven by commercial, industrial, and residential projects. The versatility of these machines aligns with Oregon’s eco-friendly and cost-efficient construction goals. By investing in a metal deck roll forming machine, businesses in Oregon can ensure local availability of high-quality metal decking while reducing costs and environmental impact.

This blog not only provides valuable insights into metal deck roll forming machines but also aligns perfectly with the needs of the Oregon construction industry, making it a go-to resource for prospective buyers.

Copyright 2026 © Machine Matcher.