To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

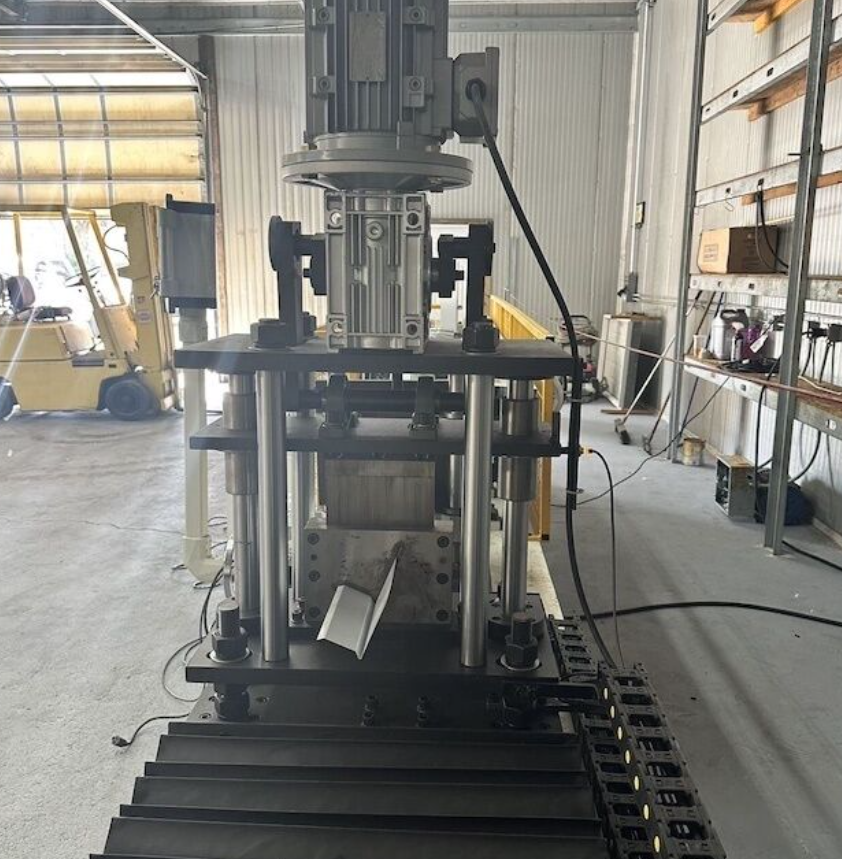

Metal Drip Edge Manufacturer Roll Forming Machine - California, USA

The Metal Drip Edge Manufacturer Roll Forming Machine is a high-performance solution designed for fabricating precise and durable drip edge profiles. Engineered to operate efficiently in high-demand manufacturing environments, this machine is ideal for metal roofing, construction, and flashing fabrication industries. Manufactured with precision, the machine is built to meet specific customer requirements and is shipped directly from our trusted manufacturing partners.

Our roll forming machine can produce a variety of standard and custom drip edge profiles, including:

This machine is widely used in various industries, including:

Each machine is custom-built based on customer-specific profiles and machine requirements. Our machines are brand new and shipped directly to the customer’s location from our manufacturing facility. We also provide optional add-ons and custom features to meet unique production needs.

Machine Matcher is a global supplier of high-quality roll forming machines, including:

We offer comprehensive machine sales, maintenance, repair, and setup services to ensure our customers achieve optimal performance in their manufacturing processes.

For pricing inquiries, optional extras, or custom machine requirements, contact us for a tailored quote. If you have profile drawings or specifications, please email details to [email protected].

Q: What power supply does this machine require?

A: This roll forming machine requires 240V three-phase 60Hz power for operation.

Q: What is the production speed of this machine?

A: The machine operates at a speed of 80 feet per minute, ensuring high efficiency in production.

Q: Can this machine produce custom drip edge profiles?

A: Yes, the machine can be customized to produce custom drip edge profiles in addition to the standard profiles.

Q: What materials can this machine work with?

A: The machine is compatible with aluminum, galvanized steel, and copper materials in various thicknesses.

Q: What are the available face sizes for the drip edges?

A: Available sizes range from 1 1/2 inches (F5) to 4 inches (F10) to accommodate different roofing applications.

Q: How long does it take to manufacture and ship the machine?

A: Lead times vary based on custom specifications, but standard production and shipping typically take 4-6 weeks.

Q: Does the machine come with a warranty?

A: Yes, all machines come with a one-year warranty covering manufacturing defects.

Q: What kind of after-sales support is provided?

A: We provide maintenance, repair, setup, and adjustment services to help customers optimize their machine's performance.

Q: How can I get a quote for this machine?

A: To receive a tailored quote, send us your profile drawings, material specifications, and any additional requirements to [email protected].

For further inquiries, reach out to Machine Matcher, your trusted supplier for premium roll forming solutions!

Copyright 2026 © Machine Matcher.