To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

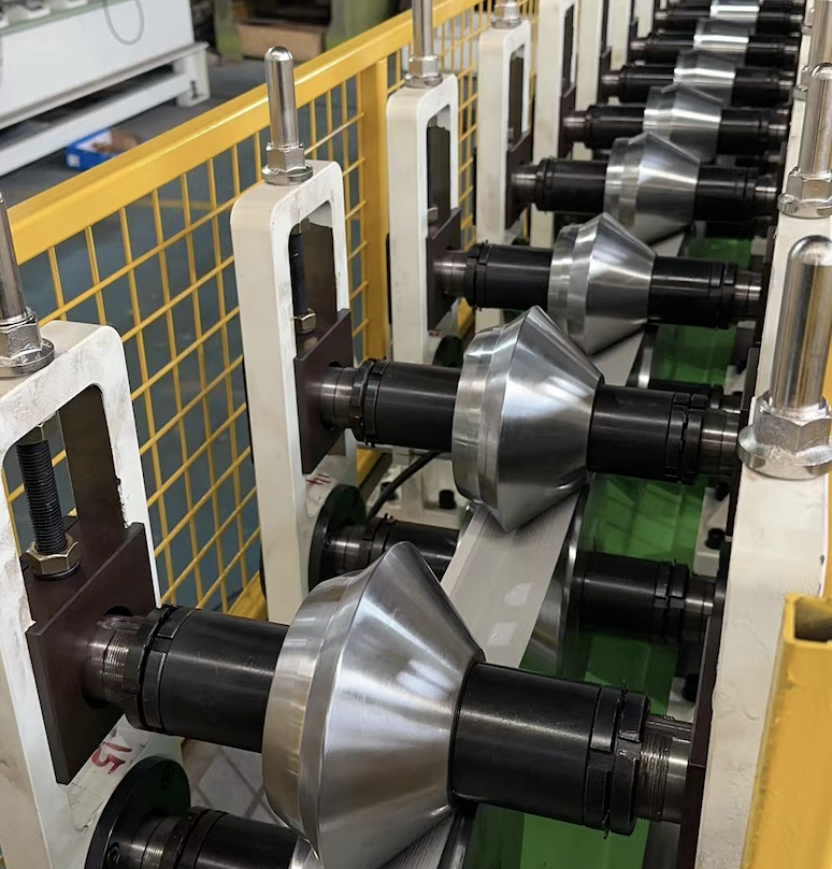

The Metal Drip Edge Roll Forming Machine is a state-of-the-art solution designed to produce high-quality drip edges for both residential and commercial roofing applications in Alaska, USA. Engineered to handle the challenging Alaskan climate, this machine is custom-built to meet specific profile and production requirements. It is part of Machine Matcher’s comprehensive lineup, which includes metal roof panel machines, metal flashing machines, purlin machines, metal trim machines, and more.

With a robust construction and advanced technology, this machine is capable of delivering precision and efficiency. It is designed to produce a variety of drip edge profiles, ensuring compatibility with different roofing systems commonly used in Alaska, from residential asphalt shingles to commercial metal roofing systems.

All machines are new, custom-built, and shipped directly to the customer’s location from our manufacturing partner. Pricing is tailored based on optional extras and customization needs. Contact us for a quote.

The Metal Drip Edge Roll Forming Machine can produce a wide range of profiles and sizes to suit various roofing applications in Alaska:

Available Profiles:

Standard Drip Edge Sizes (Face Width):

Common Widths (Horizontal Overhang):

Material Thickness (Gauge):

Common Materials:

This machine is particularly useful for the roofing industry in Alaska, where harsh weather conditions demand durable and reliable roofing solutions. Industries that benefit from this machine include:

1. Can this machine handle custom drip edge profiles?

Yes, all machines are custom-built to accommodate specific profile requirements, including unique drip edge profiles.

2. What are the power requirements for this machine in Alaska?

The machine requires a 240V three-phase 60 Hz power supply, which is standard for most industrial facilities in Alaska.

3. How long is the warranty, and what does it cover?

The machine comes with a 1-year warranty covering parts and manufacturing defects from the date of dispatch.

4. Is maintenance and repair support available in Alaska?

Yes, Machine Matcher offers comprehensive maintenance and repair services in Alaska.

5. How can I get a quote for this machine?

To receive a tailored quote, please send your profile drawings and requirements to [email protected].

6. What are the shipping options for Alaska?

We provide direct shipping to customer locations in Alaska, ensuring timely and secure delivery.

7. Can this machine handle heavy-duty materials like galvanized steel and copper?

Yes, the machine is designed to process a variety of materials, including aluminum, galvanized steel, and copper, with different gauges for residential and commercial applications.

8. Is installation included with the purchase?

Machine Matcher offers setup and installation support to ensure the machine is operational upon delivery.

For more information or to request a quote, contact us at [email protected].

Copyright 2026 © Machine Matcher.