To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

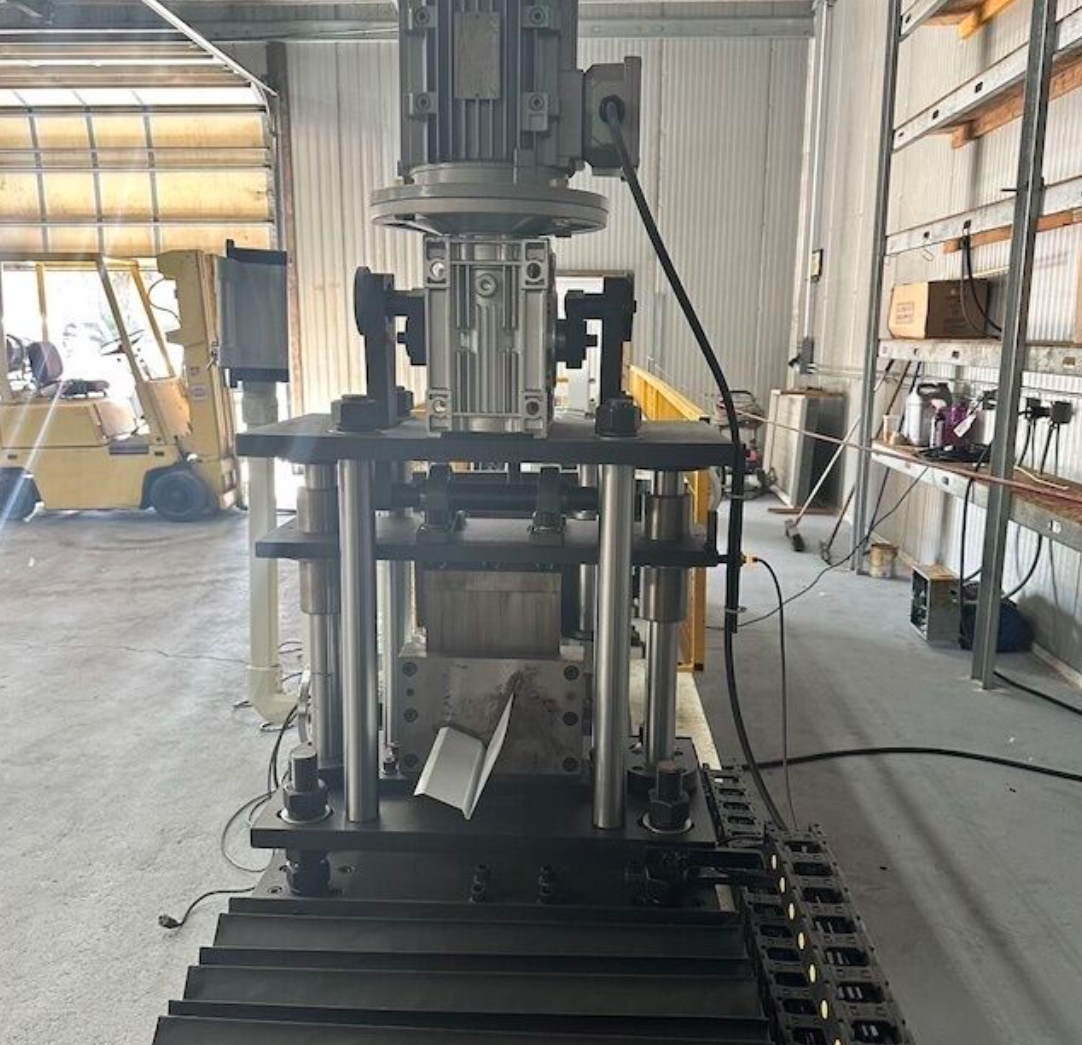

The Metal Drip Edge Roll Forming Machine is expertly designed for manufacturers in Alabama, USA, seeking to produce high-quality drip edges efficiently and with precision. Built to handle the demands of the local roofing and construction markets, this machine offers versatility, speed, and accuracy, ensuring that every profile meets industry standards.

With a robust frame and advanced features, this roll forming machine is capable of producing a wide range of drip edge profiles, including C5, C6, F4, 90 Degree, D Style, FHA, and even custom profiles. It’s engineered for high performance, capable of processing materials at a speed of 80 feet per minute, making it an ideal choice for manufacturers aiming to optimize production without compromising quality.

The Metal Drip Edge Roll Forming Machine is designed for easy installation, requiring minimal setup time. Comprehensive installation manuals and remote support are available to assist local manufacturers in Alabama.

Routine maintenance is simple and includes:

Pricing is determined based on optional extras and customization requirements. Contact us for a tailored quote based on your specific needs.

Q1: What power supply does this machine require?

A: The machine requires a 240V, three-phase, 60 Hz power supply, which is standard for industrial applications in Alabama, USA.

Q2: What materials can this roll forming machine process?

A: It is capable of processing galvanized steel, aluminum, and other standard drip edge materials.

Q3: How fast can this machine produce drip edges?

A: The machine operates at a speed of 80 feet per minute, making it highly efficient for large-scale production.

Q4: Can this machine produce custom profiles?

A: Yes, the machine supports custom profile production in addition to standard profiles like C5, C6, F4, and more.

Q5: Is on-site installation support available in Alabama?

A: Yes, we provide comprehensive installation support, including manuals and remote assistance.

Q6: How is the pricing determined?

A: Pricing is based on optional extras and customization requirements. Contact us for a detailed and personalized quote.

Q7: What kind of maintenance does the machine require?

A: Routine maintenance includes lubrication, roller and cutter inspections, electrical system checks, and regular cleaning.

Q8: Are there safety features integrated into this machine?

A: Yes, the machine is equipped with safety guards and emergency stop buttons, complying with OSHA standards for industrial safety.

Q9: What are the available drip edge profiles?

A: Available profiles include C5, C6, F4, 90 Degree, D Style, FHA, and custom profiles based on your requirements.

Q10: Can I upgrade the machine with additional features later?

A: Yes, optional extras such as remote PLC control systems, automated stackers, and uncoilers can be integrated at any time.

For more information or to get a personalized quote, contact us today!

Copyright 2026 © Machine Matcher.