To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

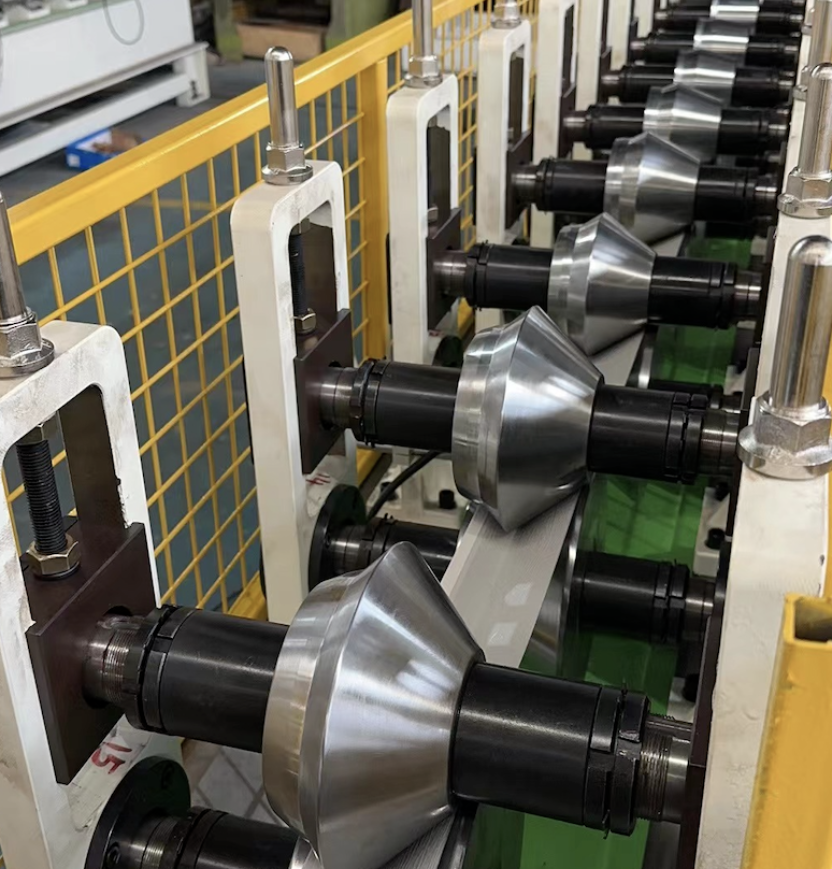

The Metal Drip Edge Roll Forming Machine is a premium solution for manufacturing a wide range of drip edge profiles used in residential, commercial, and industrial roofing systems. Built to the highest standards, this machine is custom-designed to meet the specific needs of roofing contractors, metal fabricators, and construction companies in Arizona, USA. With a focus on precision, efficiency, and durability, this roll forming machine ensures high-quality output while minimizing waste.

All machines are new and custom-built based on customer requirements, including specific profiles and customization options. They are shipped directly from our manufacturing partners to the customer’s location in Arizona. Machine Matcher offers comprehensive support, including sales, maintenance, repair, setup, and adjustments, ensuring smooth operation and maximum uptime.

The Metal Drip Edge Roll Forming Machine is designed for a variety of industries, including:

The machine comes with a detailed setup and installation guide, and Machine Matcher offers support services to ensure seamless integration at the customer’s site.

The Metal Drip Edge Roll Forming Machine can produce standard profiles like C5, C6, F4, D Style, FHA, and 90 Degree, as well as custom profiles based on customer requirements.

Yes, the machine can be customized to accommodate different material thicknesses (0.019 to 0.032 inches) and various profile sizes, including custom requests.

The machine requires a 240V three-phase power supply at 60 Hz, which is standard for industrial equipment in Arizona.

The machine operates at a speed of up to 80 feet per minute, ensuring high efficiency for large-scale production.

Yes, optional extras include remote PLC systems, stackers, coil car tippers, uncoilers, and recoilers for enhanced functionality and efficiency.

To get a tailored quote, please send your specific requirements, including profile drawings, material specifications, and any customization needs, to [email protected].

Yes, we offer comprehensive training and support to ensure your team can efficiently operate and maintain the machine.

The one-year warranty covers all parts and manufacturing defects from the date of dispatch, including maintenance support.

For more information or to get a personalized quote, contact us at [email protected] or visit our website.

Copyright 2026 © Machine Matcher.