To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

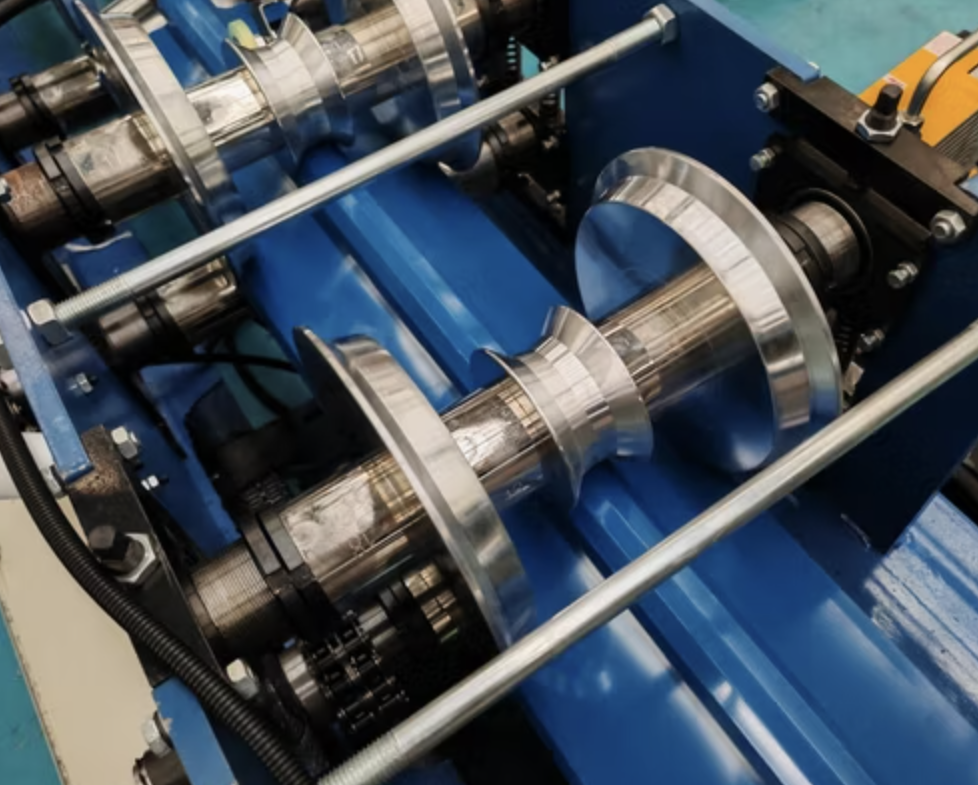

A Metal Flashing Siding Roll Forming Machine is a specialized manufacturing system designed to produce high-quality metal flashing and siding profiles. These profiles are essential for creating weather-resistant seals around windows, doors, roofs, and other building components. The machine ensures precision, consistency, and efficiency, catering to the growing demand for durable metal siding in the USA construction and home improvement sectors.

The machine processes metal coils into customized flashing and siding profiles through a series of rollers and cutting mechanisms. Its automated design reduces labor costs, speeds up production, and minimizes waste.

Q1: What are the primary uses of a Metal Flashing Siding Roll Forming Machine?

A1: The machine is used to produce metal flashing and siding profiles that provide weatherproofing and aesthetic finishes for buildings. These profiles are commonly used in roofing, windows, doors, and wall construction.

Q2: What materials can this machine process?

A2: The machine can process galvanized steel, aluminum, and stainless steel, with thicknesses ranging from 0.3 to 0.8 mm.

Q3: Is the machine suitable for small-scale production?

A3: Yes, it can be customized for smaller production batches, but its high-speed capabilities make it ideal for medium to large-scale manufacturing.

Q4: What is the average production speed?

A4: The production speed ranges from 20 to 30 meters per minute, depending on the material and profile requirements.

Q5: How is maintenance handled?

A5: Regular maintenance includes cleaning the rollers, lubricating moving parts, and checking the hydraulic and electrical systems. Manufacturers often provide detailed maintenance schedules and training.

Q6: Are there financing options available for purchasing the machine in the USA?

A6: Many suppliers offer financing options, including leasing and installment plans. It's recommended to discuss this with your supplier.

Q7: Can the machine produce custom profiles?

A7: Yes, the machine can be programmed to produce customized flashing and siding profiles based on specific requirements.

Q8: What industries benefit the most from this machine?

A8: Construction, home improvement, and industrial manufacturing industries gain the most value from this machine due to its efficiency and precision.

Copyright 2026 © Machine Matcher.