To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

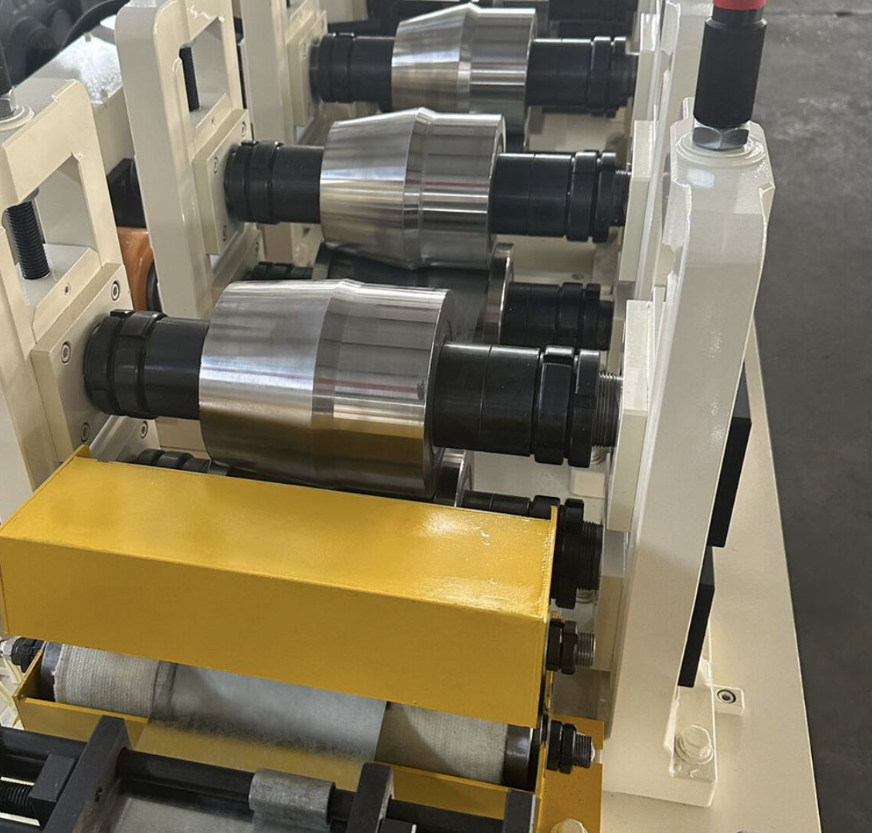

A Metal J Channel Roll Forming Machine is a specialized piece of equipment designed to produce precise and durable J channel profiles commonly used in construction, roofing, and cladding applications. These machines ensure high efficiency and consistent quality, making them indispensable for manufacturers serving industries like construction, automotive, and metal fabrication in the USA.

The Metal J Channel Roll Forming Machine is designed to produce J channel profiles from various materials, including galvanized steel, aluminum, and stainless steel. It automates the process, reducing manual labor and minimizing waste while maintaining tight tolerances and uniform shapes.

This machine features a robust steel frame and advanced components for durability and precision. Equipped with a user-friendly PLC system, it offers smooth operation and customization options for different channel dimensions and material gauges. The machine is capable of high-speed production, making it ideal for mass production in industrial settings.

Q1: What materials can the Metal J Channel Roll Forming Machine handle?

A: The machine can process galvanized steel, stainless steel, aluminum, and other metals with thicknesses ranging from 0.3mm to 2.0mm.

Q2: Can the machine produce multiple sizes of J channels?

A: Yes, the machine is customizable and adjustable to produce various J channel dimensions as per customer requirements.

Q3: How fast can the machine produce J channels?

A: The production speed ranges from 20 to 30 meters per minute, depending on the complexity of the profile.

Q4: What power supply is needed for the machine?

A: The machine typically requires 220V/380V, 50Hz/60Hz, but it can be adapted to other power specifications based on customer needs.

Q5: What optional features are available with the machine?

A: Optional features include automatic stackers, remote PLC systems, uncoilers, recoilers, and coil car tippers to enhance productivity and ease of use.

Q6: Is the machine suitable for small-scale manufacturers?

A: While it is designed for high-speed production, the machine can also be adapted for small-scale operations with the appropriate configurations.

Q7: What maintenance does the machine require?

A: Routine maintenance includes lubrication of moving parts, inspection of rollers and cutting systems, and regular cleaning to ensure optimal performance.

Q8: Can the machine be shipped and installed in the USA?

A: Yes, the machine can be shipped to any location in the USA, and professional installation and training services are available upon request.

Copyright 2026 © Machine Matcher.