To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

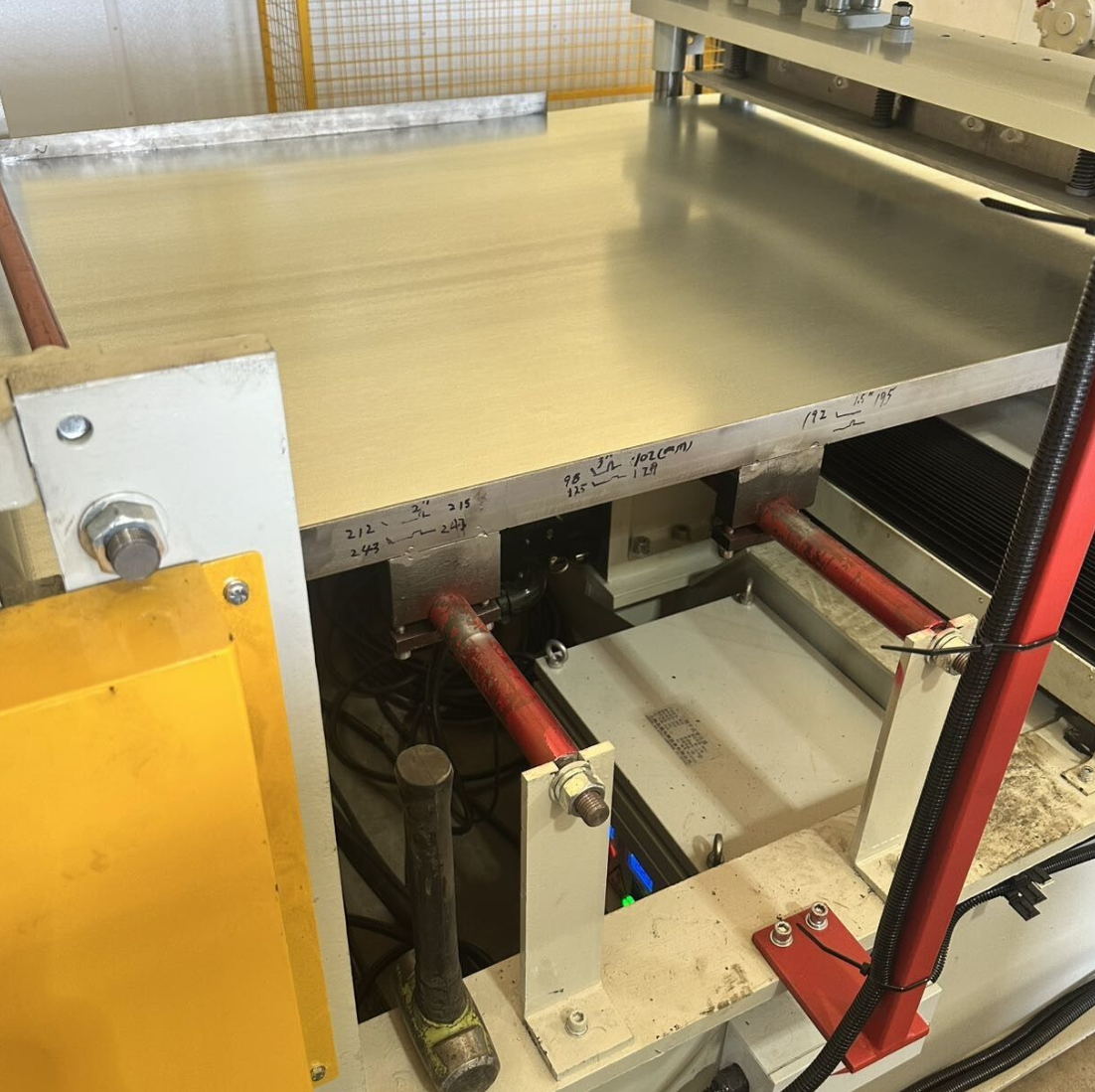

Metal Roof Deck & Floor Deck Roll Forming Machine – Available in Connecticut, USA

Custom Profiles | High Speed | Heavy-Duty Production

Product Overview

Machine Matcher proudly offers a high-performance Metal Roof Deck and Metal Floor Deck Roll Forming Machine located in Connecticut, USA, engineered for durability, accuracy, and efficient production. This machine is designed for use in commercial construction, structural decking, industrial buildings, and large-scale infrastructure projects where metal decking is essential for supporting concrete slabs or as roofing substrate.

With the ability to form various profiles including 1.5" B Deck, 3" N Deck, Composite Metal Deck, Steel Form Deck, and custom-designed options, this machine offers maximum versatility. Whether you're producing roof decking, floor decking, or custom decking panels, this machine delivers reliable output with a speed of 60+ feet per minute.

Machine Specifications

Industries Served

This roll forming machine is ideal for manufacturers and contractors in the following industries:

Delivery and Manufacturing

Every machine is custom-built to meet your exact profile and production requirements. It will be shipped directly from our manufacturing partner to your location in Connecticut or nationwide. Optional features such as auto stackers, cassettes, remote PLC access, and coil handling systems are available upon request.

Request a Quote

Pricing depends on selected profile, optional extras, automation level, and specific customization needs. For the most accurate quote, please provide your profile drawing, material gauge, coil width, and production requirements.

Email your specifications to: [email protected]

Frequently Asked Questions

Q: Can this machine handle both roof and floor deck profiles?

A: Yes. This roll former can be configured to produce multiple deck profiles including B Deck, N Deck, composite, and steel form deck. Cassette systems are available for easier profile changeover.

Q: Is it possible to order a machine for a completely custom deck profile?

A: Absolutely. We specialize in custom-built roll forming machines. Just send us your profile drawing or design requirements for a tailored solution.

Q: What material thicknesses does this machine support?

A: It can process steel from 18 gauge to 22 gauge, which covers most common roofing and flooring applications.

Q: Can the machine be operated by a standard power setup in the USA?

A: Yes, it operates on 480V, 3-phase, 60Hz, which is standard for industrial facilities in the U.S.

Q: Is installation support provided in Connecticut or the U.S.?

A: Yes. We provide full setup, calibration, and training support for customers in Connecticut and across the U.S., either on-site or remotely depending on your preference.

Q: Does this machine include an uncoiler?

A: Yes, it comes standard with a 15,000 lb hydraulic uncoiler with a coil car for efficient coil handling.

Q: What kind of maintenance is required?

A: Basic daily cleaning, periodic lubrication, and regular inspection of rollers, motors, and shear blades. Our team offers full support and can walk you through a proper maintenance schedule.

Why Choose Machine Matcher?

Machine Matcher is a global supplier of new and custom roll forming equipment. We serve customers across North America and beyond, offering machines for roof panels, flashing, trim, purlins, slitting, tile, uncoilers, embossers, and more.

We also provide repair services, on-site setup, and machine fine-tuning for optimal performance.

For questions or to discuss your project, email us today at [email protected] and get started with the right machine solution for your business.

Copyright 2026 © Machine Matcher.