To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

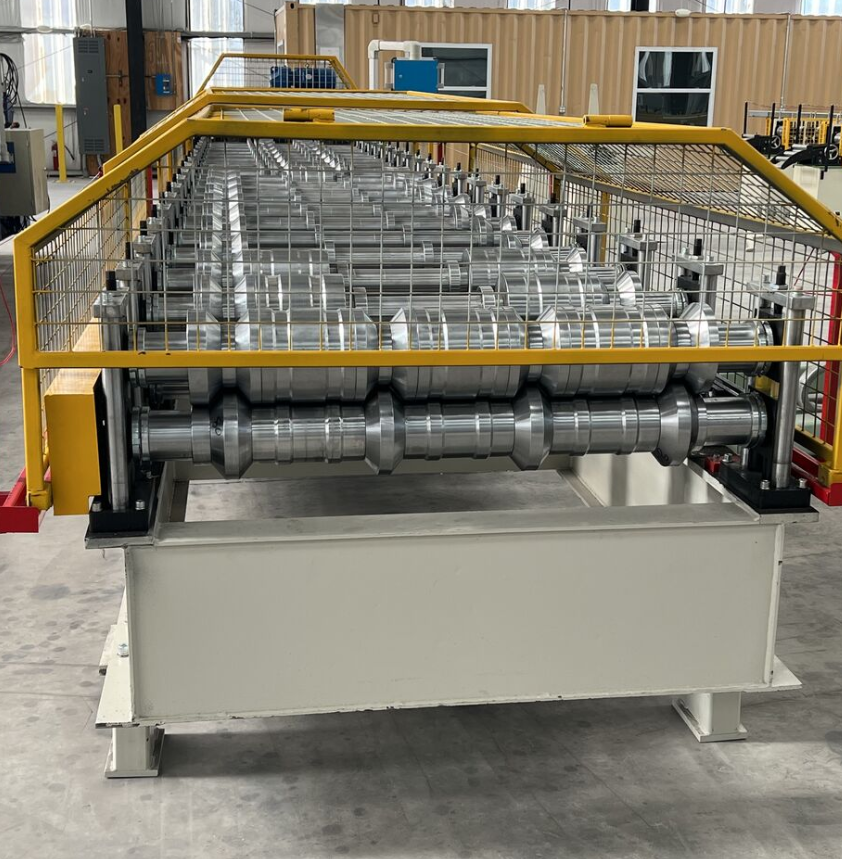

Metal Siding and Roofing Roll Forming Machine - Colorado, USA

The Metal Siding and Roofing Roll Forming Machine is a high-performance, industrial-grade system designed to manufacture durable and precise metal panels for roofing and siding applications. Engineered for efficiency and long-term reliability, this machine is custom-built to meet the exact profile and production requirements of customers in Colorado, USA. Whether for residential, commercial, or industrial metal construction, this roll forming machine is the perfect investment for businesses looking to enhance productivity and ensure consistent, high-quality output.

All machines are brand new, custom-built, and shipped directly from our manufacturing partner to your location in Colorado. With a one-year warranty from dispatch and ongoing maintenance and repair support, this machine is designed for long-term, efficient production.

This roll forming machine is ideal for industries such as:

With the ability to process a variety of gauges and customize profiles, this machine is a versatile solution for roofing and siding panel production in the Colorado construction market, where weather-resistant metal panels are essential.

Each Metal Siding and Roofing Roll Forming Machine is custom-built based on the customer’s specific profile and production requirements. The machine is tailored to meet local industry demands in Colorado, USA, ensuring seamless integration into existing production lines.

Pricing is determined based on:

For an accurate quote tailored to your needs, contact us directly or email your profile drawings and specifications to [email protected].

Machine Matcher supplies customers worldwide with high-quality roll forming solutions, including:

We provide comprehensive machine sales, maintenance, repair, machine setup, and adjustments to support businesses in the roll forming industry.

Each machine is custom-built, and the manufacturing process typically takes 6-10 weeks, depending on specifications. Shipping timelines vary based on location and logistics arrangements.

Yes! The machine can be designed to accommodate multiple profiles with additional tooling and setup.

It is designed for galvanized steel, aluminum, and other metal sheets within the 24g to 29g thickness range.

Yes, we provide operator training and technical support upon installation.

The power supply is customized based on the customer's facility requirements, ensuring seamless integration.

Simply email your profile drawings and specifications to [email protected], and our team will provide a tailored quote based on your exact needs.

Yes! All our roll forming machines come with a one-year warranty from dispatch, covering defects and technical support.

For more information or to place an order, contact us today at [email protected]!

Copyright 2026 © Machine Matcher.