To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

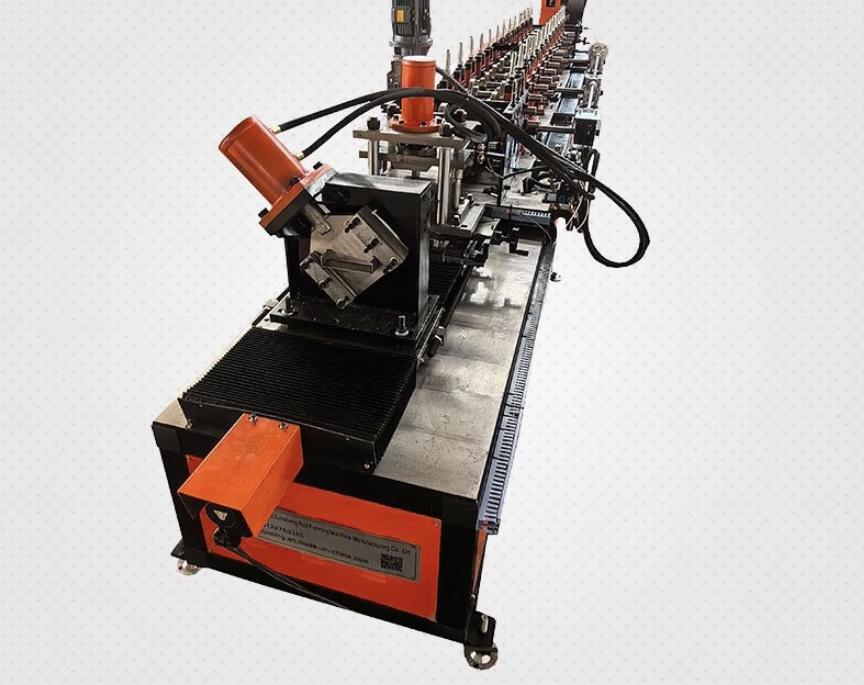

This shape profile roll forming machine is fully automatic and high speed producing continuously, one set of forming rolls can produce various sizes of Stud and Runner just by PLC,it is full automatic adjusting.

A drywall stud and track roll forming machine usually consists of manual decoiler, a feeding guide unit, a punching tool, a roll forming unit, a cutting unit, a transmission unit, a hydraulic unit, a control unit, and run-out tables. Under PLC control system, this drywall stud and track roll forming machine fully automatically produces 4-6 metal c studs or u tracks out of galvanized steel.

Effective width:Follow with design

Material Thickness: 0.4-1.0mm

Applicable material:Galvanized Steel(GI),Hot Roll Steel(HRC),With yield strength G235-390Mpa

Rolling Forming System

Forming mold: Cr12 molding steel, through vacuum quenching heat treatment to HRC60-62 °then grinding the inner

Hole and the end face. The precision machining roller surface with CNC lathe

Shafts material: 40Cr steel,CNC lathes,Heat Treatment,hard Chrome Coated

With thickness 0.04mm,surface with mirror treatment(for longer life and anti-rust)

Main motor and 14 reducers combination driving,about 12-step to form

Main Motor =5.5KW,Frequency speed control

Copyright 2026 © Machine Matcher.