To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

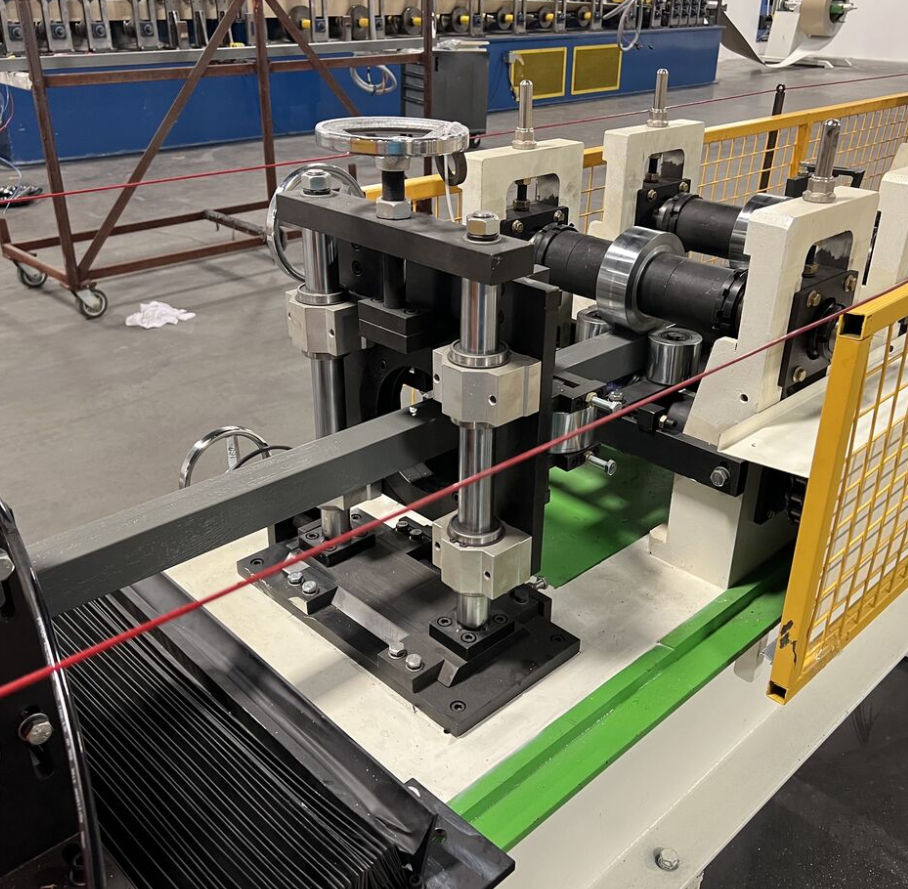

A metal tube cold roll forming machine is a specialized piece of equipment used to produce metal tubes and pipes of various shapes, sizes, and thicknesses through a cold roll forming process. The machine operates without the need for heating, making it energy-efficient while ensuring high precision and smooth finishes. These machines are widely utilized in industries such as construction, automotive, furniture manufacturing, and piping systems.

| Component | Details |

|---|---|

| Material Type | Steel, stainless steel, aluminum, copper, galvanized steel |

| Tube Profiles | Round, square, rectangular, and custom shapes |

| Tube Size Range | Diameter: 10 mm - 200 mm; Wall Thickness: 0.5 mm - 5 mm |

| Roller Material | Cr12 steel or GCr15 with heat treatment for durability |

| Forming Speed | 15-30 meters per minute (customizable) |

| Cutting System | Hydraulic or servo motor-controlled cutting |

| Main Motor Power | 11 kW to 37 kW (based on machine size and material type) |

| PLC System | Mitsubishi, Siemens, or Schneider |

| Frame Structure | Heavy-duty welded steel frame |

| Drive System | Chain drive or gearbox drive |

| Electrical System | 220V/380V/415V, 50/60Hz (customized as per Florida standards) |

| Control Panel | Touchscreen interface with pre-programmed settings |

| Optional Extras | Uncoiler, recoiler, inline welding system, punching system, stackers |

| Safety Features | Enclosures, emergency stop buttons, and safety guards |

Q1. What industries commonly use this machine in Florida?

A1. Common industries include construction (structural pipes), automotive (exhaust systems), furniture manufacturing, and piping systems.

Q2. What materials can this machine process?

A2. It can process a variety of materials including steel, stainless steel, aluminum, and galvanized steel.

Q3. Is the machine compatible with Florida's power supply standards?

A3. Yes, the machine can be customized for 220V, 380V, or 415V power requirements as per Florida regulations.

Q4. Can the machine produce custom tube profiles?

A4. Yes, with proper roller design, the machine can manufacture custom tube shapes.

Q5. How much space is required to install the machine?

A5. Depending on the model, a standard machine requires 10m x 3m space, including room for material handling.

Q6. Is operator training necessary?

A6. Yes, training is crucial to ensure safe and efficient operation.

Q7. How does the machine ensure precision in tube production?

A7. Precision is achieved through high-quality rollers, an advanced PLC system, and accurate calibration.

Q8. What is the lead time for delivery in Florida?

A8. Lead time typically ranges from 6 to 10 weeks, depending on customization requirements.

Q9. What safety measures are included?

A9. Safety features include enclosures, emergency stop buttons, and operator training to minimize risks.

Q10. Can this machine be upgraded with additional features?

A10. Yes, optional extras such as uncoilers, inline welding systems, and stackers can be added.

Copyright 2026 © Machine Matcher.