To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

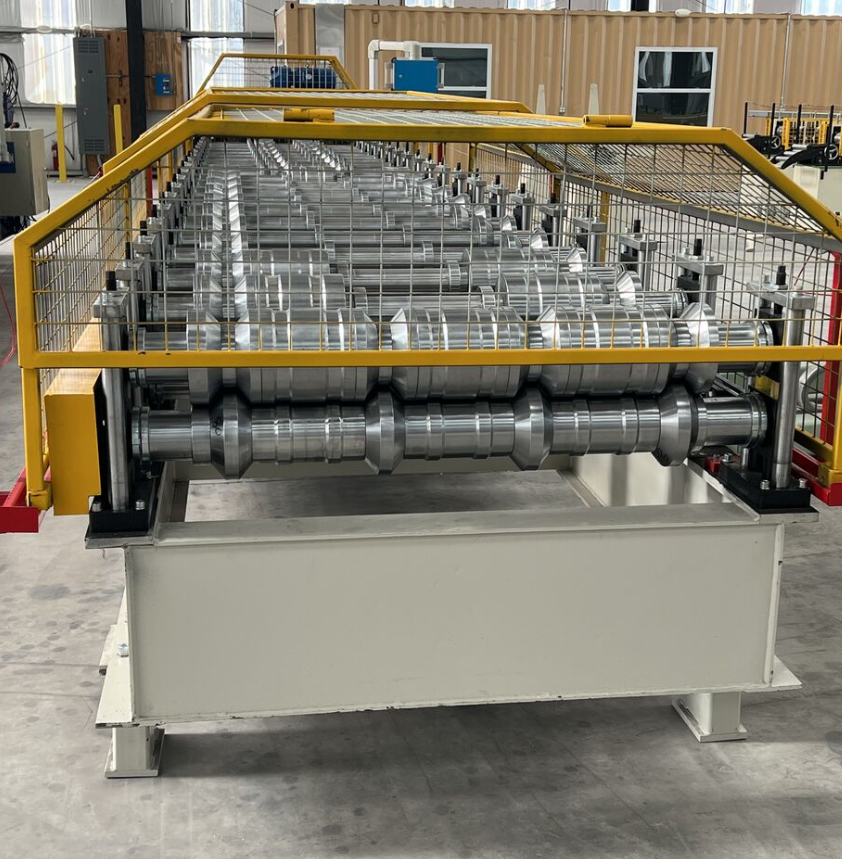

PBR-Panel Roll Forming Machine – Architectural Sheet Metal & Panel Production

Location: Colorado, USA

The PBR-Panel Roll Forming Machine is a high-performance solution designed for manufacturing PBR metal roof panels, commonly used in architectural sheet metal applications. This heavy-duty roll forming system is ideal for producing precise and durable panels, meeting industry standards for strength and efficiency.

Engineered for reliability, this machine is built to handle a range of material gauges and incorporates advanced automation for optimized production. It is perfect for roofing, siding, and structural panel fabrication, catering to contractors, manufacturers, and metal building professionals in Colorado and beyond.

The PBR-Panel Roll Forming Machine serves industries such as:

Each PBR-Panel Roll Forming Machine is custom-built to meet the specific profile and production needs of our customers. The machine is shipped directly from our manufacturing partner to your location in Colorado or any other specified destination.

Machine Matcher supplies a wide range of roll forming equipment, including:

We also provide complete sales, maintenance, repair, setup, and adjustment services for roll forming machines.

To receive the most accurate quote for your PBR-Panel Roll Forming Machine, please email your profile drawings and specific requirements to [email protected].

This machine is designed to produce PBR metal roof panels, commonly used in commercial, industrial, and residential construction.

Yes, the machine can process 24g to 29g metal sheets, making it versatile for various roofing and cladding applications.

The computerized batching system automates panel length and quantity, improving production efficiency and reducing waste.

The 10,000lb uncoiler with a car ensures smooth coil handling, while the auto stacker organizes finished panels for easy transportation and storage.

The machine is shipped directly from our manufacturing partner to your location. Installation and setup support are available upon request.

Regular maintenance includes lubrication of moving parts, checking alignment, and ensuring the chain drive operates smoothly. Our team provides durable maintenance and repair support.

Pricing is customized based on optional features and specifications. Send your requirements and profile drawings to [email protected] for an accurate quote.

For more details or to request a quote, contact us today!

Copyright 2026 © Machine Matcher.