To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

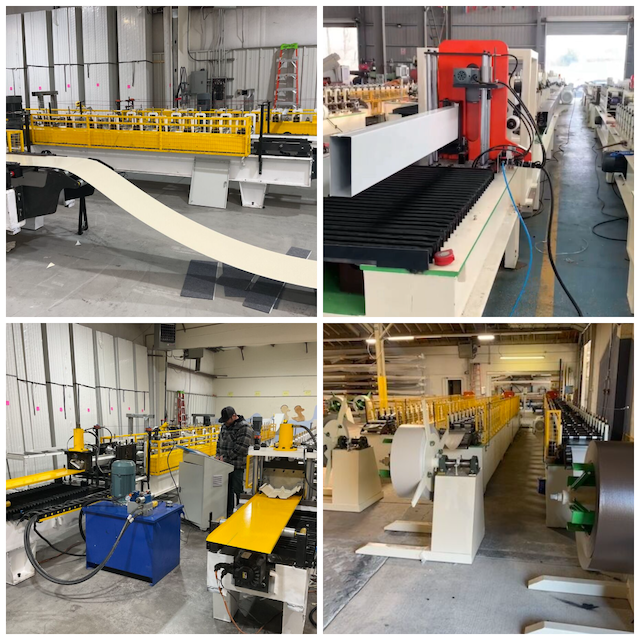

The Pergola Beam Roll Forming Machine is a cutting-edge solution designed for the efficient production of high-quality pergola beams. Specifically tailored for the USA market, this machine meets the rigorous demands of modern architecture and outdoor structures. With its robust build, precision engineering, and user-friendly controls, it is an essential tool for manufacturers in the construction and landscaping industries.

The Pergola Beam Roll Forming Machine offers unparalleled efficiency and accuracy in forming durable and aesthetically pleasing pergola beams. Its advanced design supports high-speed operation, making it ideal for large-scale production. The machine is built to cater to the unique needs of the U.S. market, complying with standard power requirements and safety regulations. It is suitable for forming beams of varying materials, including aluminum, galvanized steel, and coated steel.

| Feature | Details |

|---|---|

| Forming Speed | 70 - 80 ft/min |

| Machine Weight | 6 Ton |

| Machine Footprint | 33 ft x 4 ft |

| Main Power | 240V - 3 Phase - 60Hz |

| Motor | 8 HP |

| Gearbox | Chain Drive |

| Stations | 22 |

| Control System | Delta PLC System |

| Safety Features | Safety Covers, E-Stops |

The Pergola Beam Roll Forming Machine produces profiles with exceptional dimensional accuracy and finish. The machine can process the following profiles:

Q1: What materials can this machine process?

A1: The Pergola Beam Roll Forming Machine can process aluminum, galvanized steel, and coated steel, making it versatile for different applications.

Q2: Is the machine compatible with U.S. power standards?

A2: Yes, the machine is designed for 240V - 3 Phase - 60Hz, adhering to U.S. power standards.

Q3: How much space is needed to install this machine?

A3: The machine requires a footprint of 33 ft x 4 ft, making it compact enough for most manufacturing spaces.

Q4: Does the machine include safety features?

A4: Yes, it includes safety covers and emergency stops (E-Stops) to ensure operator safety.

Q5: Can the machine produce custom profiles?

A5: Absolutely. The machine can be adjusted to produce custom pergola beam profiles as per client specifications.

Q6: What is the machine's weight, and how does it affect installation?

A6: The machine weighs 6 tons, ensuring stability during operation. Proper handling equipment is required for installation.

Q7: Is training required to operate the machine?

A7: Basic training on the Delta PLC system is recommended for efficient operation.

The Pergola Beam Roll Forming Machine is a versatile, high-speed solution tailored to meet the needs of the U.S. market. With its robust construction, precision engineering, and safety features, it is an excellent investment for manufacturers aiming to produce high-quality pergola beams efficiently.

Copyright 2026 © Machine Matcher.