To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

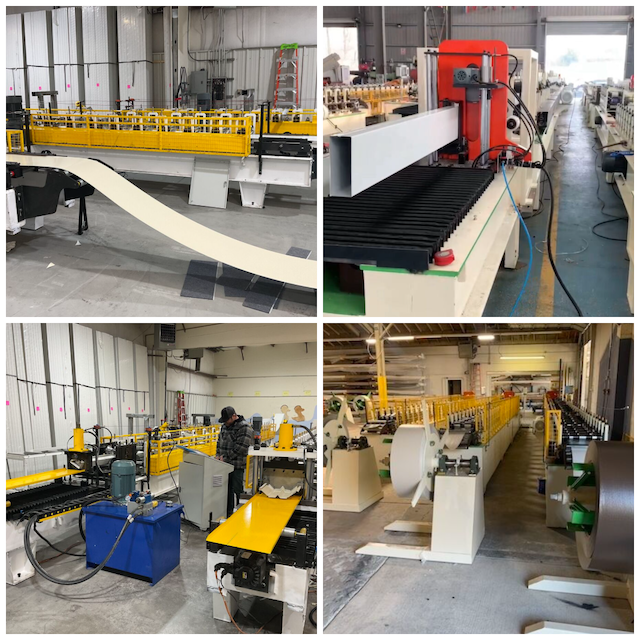

A Pergola Column Roll Forming Machine is a specialized manufacturing unit designed to produce high-quality metal columns used in pergola structures. These machines cater to the growing demand for stylish and durable pergola systems in residential and commercial landscaping projects. Designed to handle the unique requirements of the USA market, this machine ensures compliance with local specifications and standards.

The Pergola Column Roll Forming Machine is engineered to provide precision and efficiency for manufacturers catering to the pergola market. Its robust build and advanced features ensure long-term reliability and consistent performance.

Key features include:

The machine is designed to produce high-quality metal columns used in pergola systems. These columns can vary in shape, size, and finish, depending on the end-user requirements.

The machine is delivered with comprehensive setup instructions and on-site installation support. A skilled technician can assist in connecting the electrical systems, calibrating the PLC, and testing the machine to ensure it is operational.

Regular maintenance ensures the longevity of the machine:

Q1: What materials can this machine process?

A1: The machine can process steel (galvanized or stainless) and aluminum, commonly used for pergola columns.

Q2: How long does it take to install and set up the machine?

A2: Installation and setup typically take 2-3 days with professional assistance.

Q3: Is the machine suitable for custom column designs?

A3: Yes, the machine can produce a variety of column profiles with adjustments to the rollers and PLC settings.

Q4: What safety features are included?

A4: The machine includes fully enclosed safety covers and multiple emergency stop buttons for enhanced safety.

Q5: Does the machine comply with USA electrical standards?

A5: Yes, it is designed for a 240V, 3-phase, 60Hz power supply, ensuring compatibility with USA standards.

Q6: What is the lead time for delivery in the USA?

A6: Typical lead time is 6-8 weeks, including shipping and customs clearance.

Q7: Are spare parts readily available?

A7: Yes, spare parts are readily available and can be shipped directly to the USA.

Q8: Can the machine integrate with an automated production line?

A8: Yes, the machine can be equipped with optional extras such as automated stackers and material handling systems.

This Pergola Column Roll Forming Machine is an ideal choice for manufacturers in the USA seeking efficiency, precision, and reliability in producing high-quality pergola columns.

Copyright 2026 © Machine Matcher.