To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

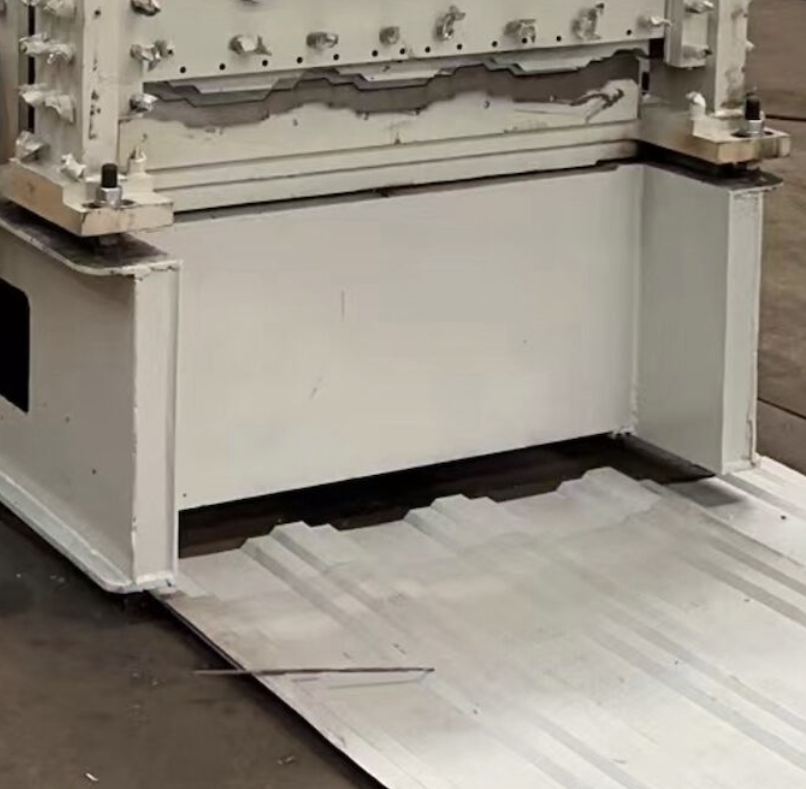

The Purlin Bearing Rib (PBR) Overlay Panel Cold Roll Forming Machine is designed to produce durable and precise PBR panels for roofing and siding applications. PBR panels are widely used in commercial, industrial, and agricultural projects due to their structural strength, weather resistance, and versatility. This machine is built for efficiency, capable of handling 41-inch coil widths and producing panels with gauges ranging from 24g to 26g. It operates seamlessly at a power specification of 240V, 3-phase, 60Hz, making it ideal for the Florida, USA market.

The machine integrates advanced technology, ensuring consistent quality and precision. Its post-shear cutting system guarantees clean and accurate cuts without deforming the panel edges. Additionally, the machine's robust construction and automated features minimize downtime and enhance production efficiency.

Q1: What power supply is required for this machine in Florida?

A: The machine is compatible with the standard Florida power supply of 240V, 3-phase, 60Hz.

Q2: What materials can the machine process?

A: The machine can process galvanized steel, aluminum, and other metals suitable for 24g to 26g thickness.

Q3: How does the post-shear system work?

A: The post-shear system uses hydraulic cutting to ensure precise cuts after the panel is formed, maintaining clean edges and profile integrity.

Q4: What is the maximum coil width supported?

A: The machine supports a coil width of up to 41 inches.

Q5: Can the machine operate continuously for long production runs?

A: Yes, the machine is designed for continuous operation with a robust frame, efficient cooling systems, and reliable components.

Q6: Are there optional extras available?

A: Yes, optional extras include automatic stackers, uncoiler and recoiler systems, remote PLC controls, and leveling systems.

Q7: How fast can the machine produce panels?

A: The machine operates at speeds of up to 30m/min, depending on the material and profile requirements.

Q8: Is the machine suitable for Florida’s construction industry?

A: Absolutely. The PBR panels produced are ideal for Florida's diverse building requirements, offering durability, weather resistance, and structural strength.

Q9: What are the maintenance requirements?

A: Regular lubrication, periodic roller inspection, and cleaning are essential. The PLC system also provides alerts for maintenance schedules.

Q10: Is training provided for operating the machine?

A: Yes, training and installation support are available to ensure smooth operation.

Copyright 2026 © Machine Matcher.