To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

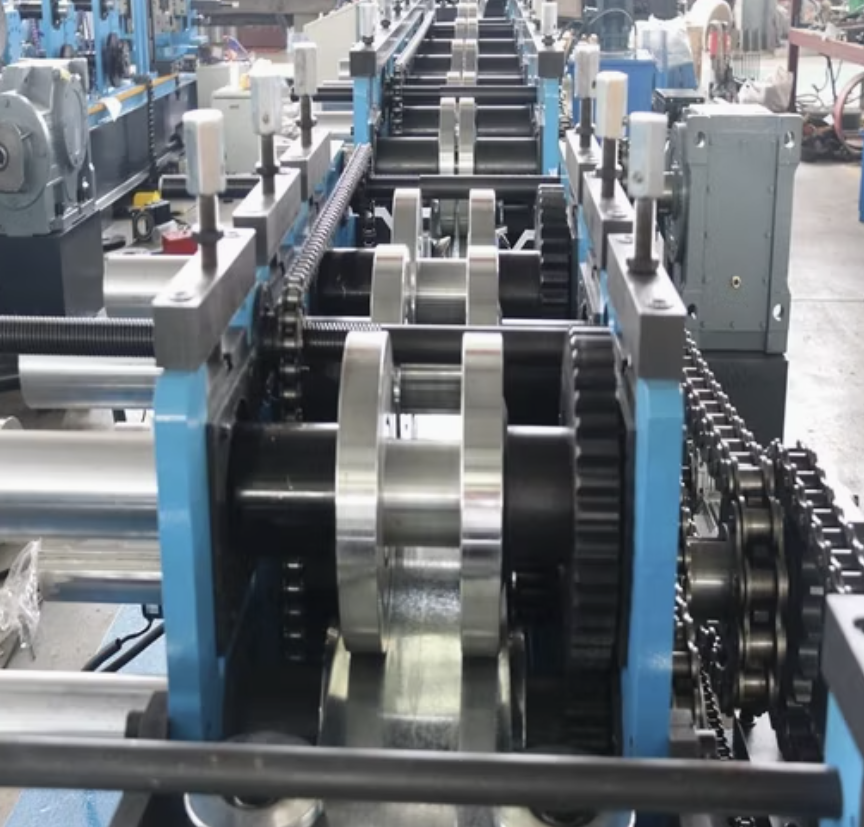

The Purlin Metal Building Roll Forming Machine is a high-performance industrial solution designed to produce C, Z, and U-shaped purlins for metal building construction. Purlins are structural components used in roofing and wall framing systems, providing support and durability. This machine offers precision, speed, and flexibility, making it an essential tool for manufacturers involved in the metal building industry.

Equipped with advanced technology, this machine can efficiently produce purlins of various sizes and thicknesses. Its versatility allows manufacturers to quickly switch between profiles, enhancing productivity and minimizing downtime. The roll forming process ensures uniformity, strength, and superior finish quality for purlins used in diverse applications, such as warehouses, commercial buildings, and residential projects.

1. Machine Components:

2. Technical Details:

3. Optional Add-Ons:

4. Safety Features:

1. What is a Purlin Roll Forming Machine used for?

The machine is used to manufacture structural purlins (C, Z, and U shapes) for supporting roofs and walls in metal building construction.

2. Can the machine handle different material types?

Yes, the machine can process galvanized steel, mild steel, and high-tensile steel, depending on the project requirements.

3. How quickly can it switch between profiles?

The quick-changeover mechanism allows profile switching within 10–15 minutes, minimizing downtime.

4. What is the typical production speed?

The machine operates at a speed of 20–40m/min, depending on the material thickness and profile type.

5. Is the machine suitable for the U.S. market?

Yes, the power supply and technical specifications can be customized to match U.S. standards (220V, 380V, or 440V).

6. What optional features are available?

Optional features include automatic stackers, pre-punching systems, remote PLC controls, and heavy-duty uncoilers.

7. How do I maintain the machine?

Regular maintenance involves cleaning the rollers, checking the hydraulic systems, lubricating moving parts, and ensuring the PLC system is updated.

8. Is training provided for operators?

Most manufacturers offer training and installation support to ensure seamless operation.

Copyright 2026 © Machine Matcher.