To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

Purlin roll forming machines are specialized industrial equipment designed to produce steel purlins used in roofing, wall framing, and structural supports in construction projects. These machines are widely adopted in the Georgia state market due to the construction boom in commercial and residential sectors. With the ability to form C, Z, U, or interchangeable profiles, these machines ensure precision, durability, and versatility, making them an indispensable asset for manufacturers and contractors.

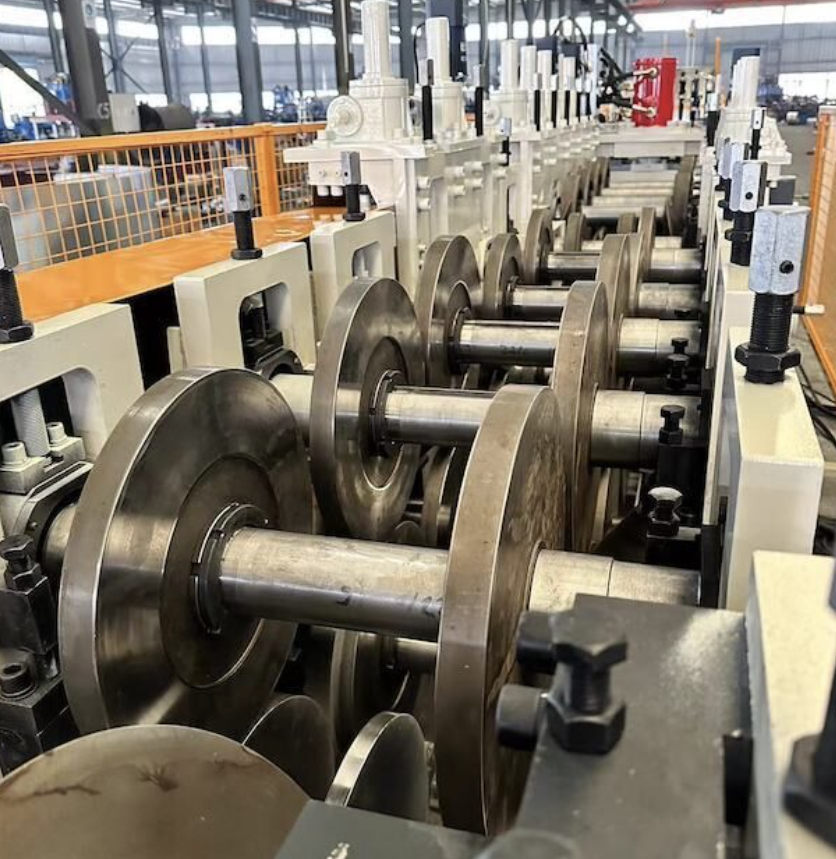

A purlin roll forming machine consists of high-grade components engineered to produce purlin profiles from steel or aluminum sheets. The process involves feeding raw material (coils), cutting, forming, and stacking the final product automatically. The machine can produce variable-sized purlins by adjusting parameters, eliminating the need for multiple setups.

Key features include:

| Parameter | Details |

|---|---|

| Roller Material | High-grade GCr15 steel with hard chrome plating for durability. |

| Profile Types | C, Z, U, and interchangeable purlins. |

| Material Thickness | 1.5mm to 3.0mm (customizable for specific needs). |

| Material Width | 100mm to 400mm adjustable. |

| Machine Speed | 10-25 m/min (varies based on the profile). |

| Frame Size | Heavy-duty H-beam structure. |

| Cutting System | Hydraulic post-cutting with servo control for precise cuts. |

| Motor Power | 15-20 kW (depending on the model). |

| PLC Control System | Mitsubishi or Siemens PLC for automatic operation. |

| Punching System | Hydraulic punching for holes (customizable based on project requirements). |

| Safety Features | Enclosures, emergency stops, and safety guards. |

| Power Supply | 220V/380V/440V, 3-phase, 60Hz (customizable for Georgia's power standards). |

In Georgia, the demand for purlin roll forming machines is growing due to:

By emphasizing customization, compliance with U.S. quality standards, and energy-efficient machines, manufacturers can penetrate the Georgia market effectively.

The cost varies based on specifications and features, ranging from $50,000 to $150,000. Customizations and optional extras like stackers and remote PLCs may increase the price.

With interchangeable profile systems, it takes about 15-30 minutes to switch between profiles, depending on the machine.

Regular lubrication, cleaning of rollers, inspection of hydraulic systems, and calibration of the PLC ensure optimal performance and longevity.

Yes, with proper configuration, it can process high-strength steel up to 3.0mm in thickness.

Most manufacturers provide on-site installation and training to ensure smooth operation.

Yes, the machines are designed with safety enclosures, emergency stops, and comply with U.S. OSHA standards.

A purlin roll forming machine is a critical investment for manufacturers and contractors in Georgia, offering the ability to produce versatile, high-quality purlins for diverse applications. With advanced automation, durability, and customizable features, these machines meet the growing demands of the construction industry while maintaining compliance with local standards. By targeting the Georgia market, businesses can leverage these machines to stay competitive and deliver exceptional results.

4o

Copyright 2026 © Machine Matcher.