To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

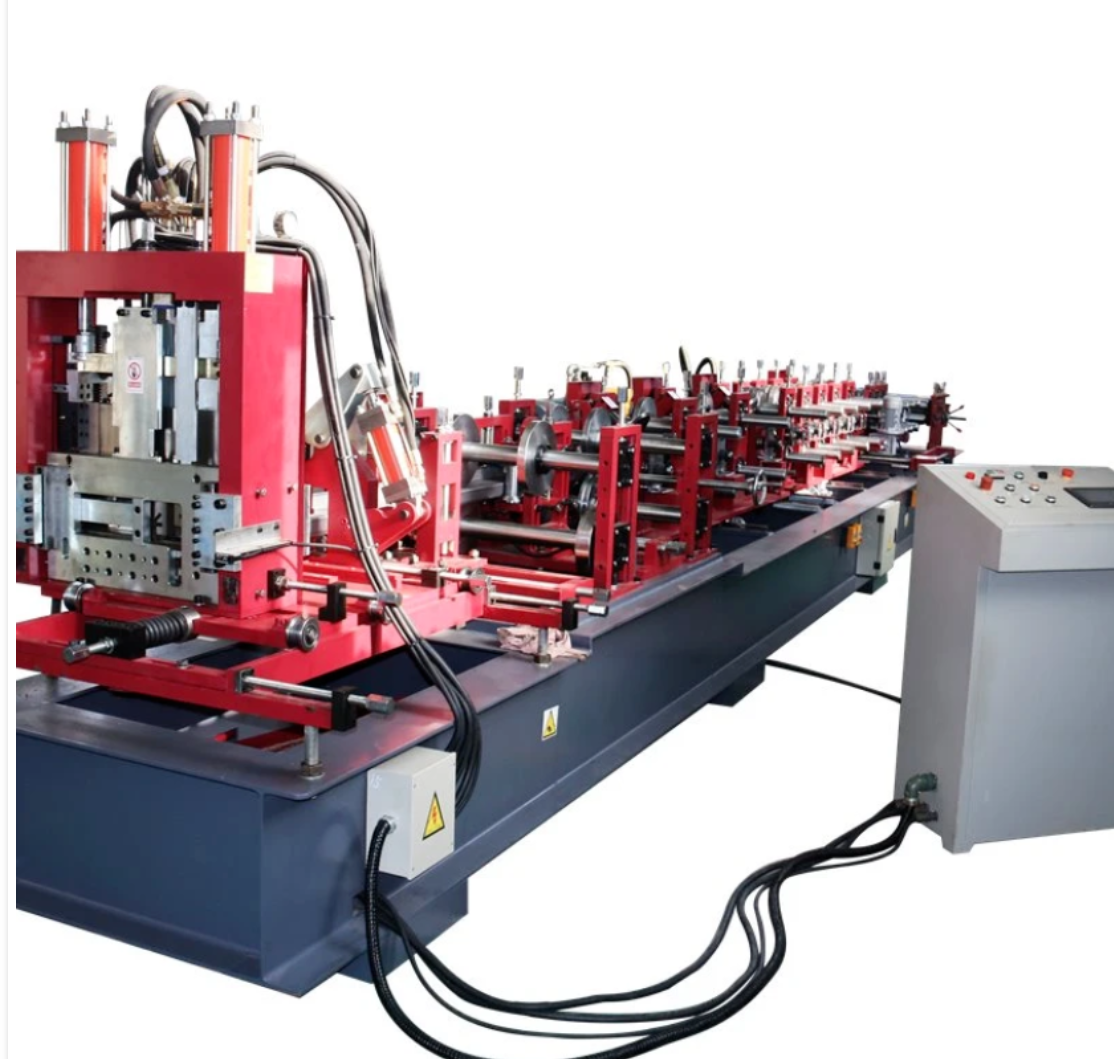

| Forming steps | 14 steps |

| Shaft diameter | 80mm |

| Machine stand | Steel Plate Welded |

| Machine frame | 350H steel |

| roller material | Cr15 with quenching |

| shaft material | 45# steel with quenching and tempering |

| Work speed | 0-15m/min |

| Transport | By chains |

| Power of main machine | 22kw |

| Voltage | 380V-50HZ-3P(as required) |

| Machine dimension | 14*1.5*1.2m |

| Machine weight | About 8.5T |

A purlin roll forming machine is designed to produce purlins, which are horizontal structural members used in buildings to support roofs and walls. This machine typically operates in a continuous process, transforming flat steel coils into shaped profiles through a series of rollers. Here’s an overview of its features, benefits, and applications:

In summary, a purlin roll forming machine is essential for manufacturers in the construction industry, enabling them to efficiently produce high-quality purlins that meet various structural requirements. If you're considering investing in a purlin roll forming machine, look for features like automation, flexibility in profile production, and strong support from manufacturers for maintenance and operation.

Copyright 2026 © Machine Matcher.