To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

Purlin roll forming machines are essential equipment for the steel construction industry, particularly in creating structural supports like Z, C, and U-shaped purlins. These machines streamline the production of high-strength, lightweight steel purlins used in roofing, wall support, and building frames. Below is a full breakdown of their features, specifications, uses, and frequently asked questions (FAQs).

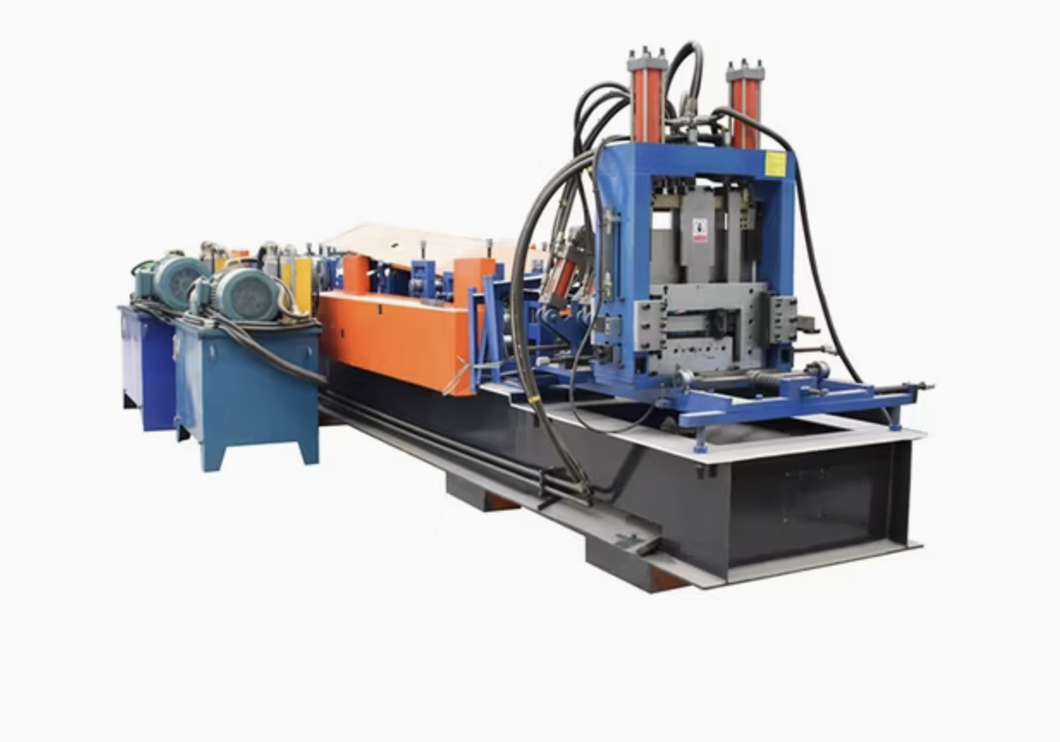

A Purlin Roll Forming Machine is a specialized piece of equipment designed to manufacture steel purlins through a cold-forming process. The machine takes in steel coils and processes them into desired purlin shapes with precise dimensions. It is widely used in industries like construction, agriculture, and warehouse infrastructure.

The machine features interchangeable rollers for producing various purlin profiles such as Z, C, and U. Advanced PLC systems allow customization of length, punching holes, and profile type. Automation and high-speed performance ensure maximum productivity and reduced waste.

Here are the typical specifications for a Purlin Roll Forming Machine available in the UK:

| Feature | Specification |

|---|---|

| Material Thickness | 1.2mm – 3.0mm (customizable) |

| Material Width | 80mm – 300mm |

| Material Type | Galvanized steel, stainless steel, carbon steel |

| Roller Material | High-grade GCr15 steel with chrome plating |

| Cutting System | Hydraulic cutting system with servo motor control |

| Frame Structure | Heavy-duty steel frame with precision welding |

| Machine Speed | 15–20 meters per minute |

| Punching System | Hydraulic or mechanical punching |

| Control System | PLC with touchscreen interface |

| Motor Power | 7.5KW to 15KW |

| Voltage | 380V, 50Hz (customizable for the UK market) |

| Profile Options | C, Z, U, and interchangeable profiles |

| Dimensions | 7,000mm x 1,500mm x 1,200mm (varies by model) |

| Weight | Approx. 6,000–8,000 kg |

| Optional Extras | Coil car, uncoiler, recoiler, stacker, leveling system |

Purlin roll forming machines are used in the following applications:

A standard purlin roll forming machine can produce C, Z, and U-shaped profiles. Advanced machines come with interchangeable rollers for flexibility.

Consider the range of material thickness, width, and profiles you intend to produce. Evaluate production volume requirements and available space in your facility.

Machines are typically configured for 380V, 50Hz, which aligns with UK industrial power standards. However, voltage customization is possible based on requirements.

Yes, hydraulic or mechanical punching systems integrated into the machine can create precise holes for connections and fittings.

Routine maintenance includes:

Yes, most advanced machines can be adjusted to handle custom profile dimensions and designs.

The price varies depending on the machine's features, automation level, and capacity, ranging from £40,000 to £100,000.

Installation is typically carried out by trained technicians provided by the manufacturer. They also provide operator training to ensure smooth operation.

Copyright 2026 © Machine Matcher.