To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

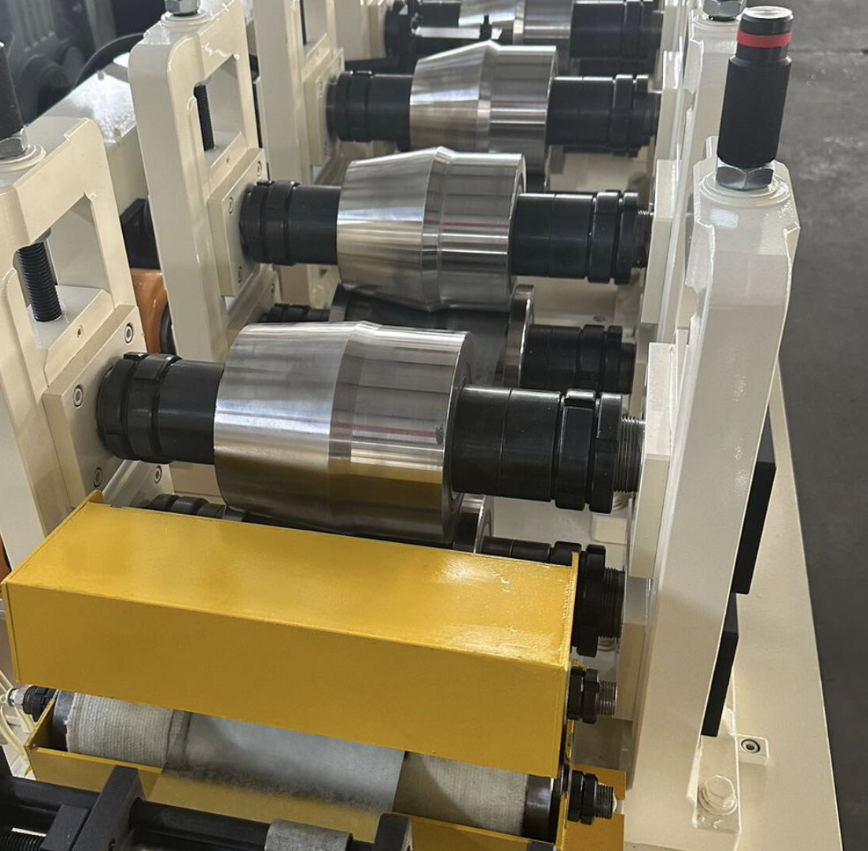

The Roof Drip Edge Roll Forming Machine is a custom-built, high-performance solution designed to manufacture a wide range of drip edge profiles for residential and commercial roofing systems. Located in Arkansas, USA, this machine is ideal for roofing contractors, metal fabricators, and manufacturers looking to streamline production and enhance output quality. Built to order and shipped directly from our manufacturing partner, this machine is engineered to meet specific profile requirements and industry standards.

The Roof Drip Edge Roll Forming Machine is widely used across various sectors, including:

Q1: What is a drip edge, and why is it important?

A: A drip edge is a metal flashing installed at the edges of the roof to direct water away from the fascia and prevent damage to the underlying roofing components. It enhances durability and prevents water infiltration.

Q2: Can this machine handle custom profiles and materials?

A: Yes, the Roof Drip Edge Roll Forming Machine is designed to handle a variety of custom profiles and materials, including aluminum, galvanized steel, and copper. Customizations are available based on specific requirements.

Q3: How fast can this machine produce drip edges?

A: The machine operates at a production speed of 80 feet per minute, ensuring high efficiency for both small and large-scale projects.

Q4: What are the power requirements for this machine?

A: The machine requires a 240V three-phase power supply at 60 Hz, suitable for most commercial and industrial setups in the USA.

Q5: Is there a warranty included with the purchase?

A: Yes, all machines come with a 1-year warranty covering parts and service support from the date of dispatch.

Q6: How can I get a quote for a custom profile?

A: To receive a tailored quote, send your profile drawings and specific requirements to [email protected]. Our team will respond promptly with detailed pricing and options.

Q7: What kind of maintenance support is provided?

A: Machine Matcher offers comprehensive maintenance and repair services, including setup, adjustments, and technical support to ensure optimal machine performance.

Q8: Can I order optional extras for enhanced functionality?

A: Yes, optional extras such as remote PLC systems, coil car tippers, and automatic stackers are available to enhance production efficiency and automation.

For more information or to request a quote, please contact us at [email protected]. Our experts are ready to assist you with all your roll forming machine needs!

Copyright 2026 © Machine Matcher.